Plastic film display support

A technology of plastic film and support body, which is applied in the field of plastic film production workshop tools, can solve the problems of film wrinkles, troublesome handling, low work efficiency, etc., and achieve the effect of avoiding wrinkles and irregularities, meeting production needs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

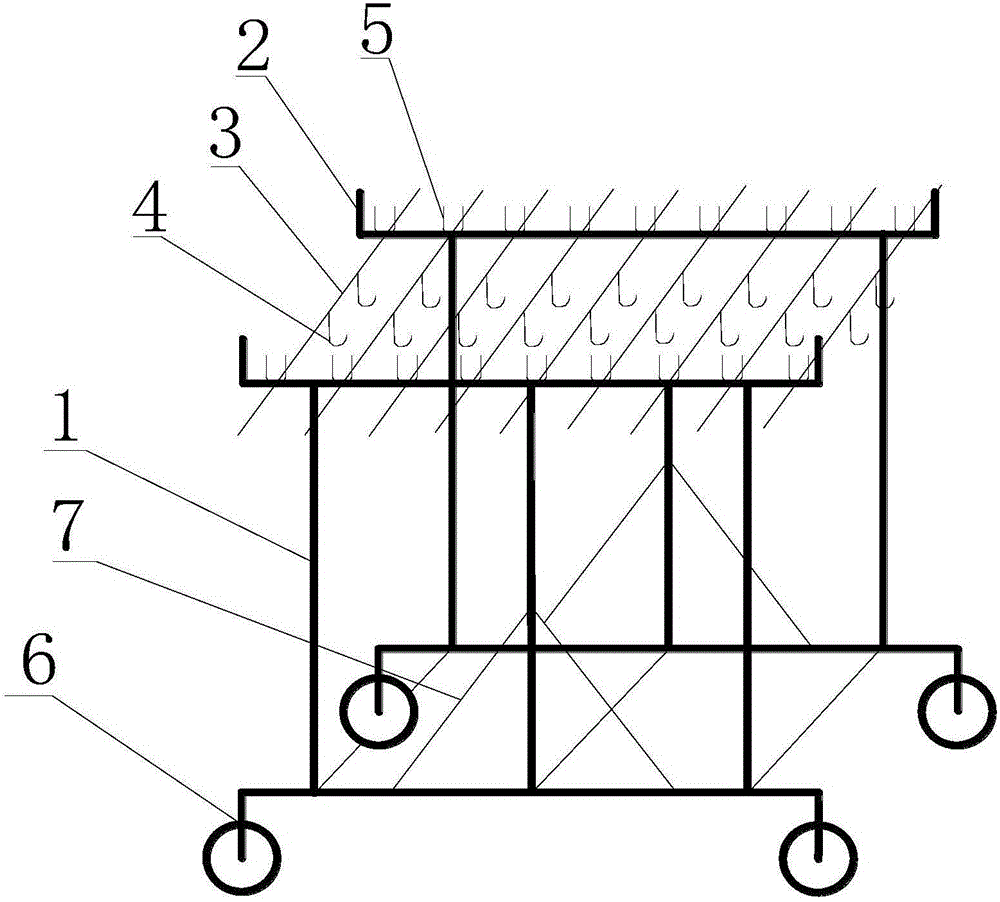

[0012] Such as figure 1 As shown, a plastic film display bracket includes a bracket body 1 and a film-hanging cross bar 3, universal rollers 6 are provided on the four corners of the bottom of the bracket body 1, and the two ends of the upper pole of the bracket body 1 are vertically arranged Limit stop rod 2, the limit stop rod 2 is a "["-shaped bracket with an upward opening, and several U-shaped cards 5 are arranged on the limit stop rod 2, and the multiple sets of U-shaped cards 5 slots Parallel film-hanging crossbars 3 are displayed, and a hook 4 is vertically arranged on the film-hanging crossbar 3. The vertical pole of the support body 1 and the pole at the bottom of the support are provided with reinforcing ribs 7, and the hook 4 has a plurality of , each interval is 10cm.

[0013] When this invention is in use, the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com