Aluminum alloy formwork opposite-pulling piece dismantling tool

A technology of aluminum alloy formwork and demolition tool, which is applied in the treatment of formwork, the preparation of building components on site, and construction, etc., can solve the problems of inconvenient operation, broken on the outside of the wall, uneven fracture, etc., and achieves high versatility. , accelerated fracture efficiency, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

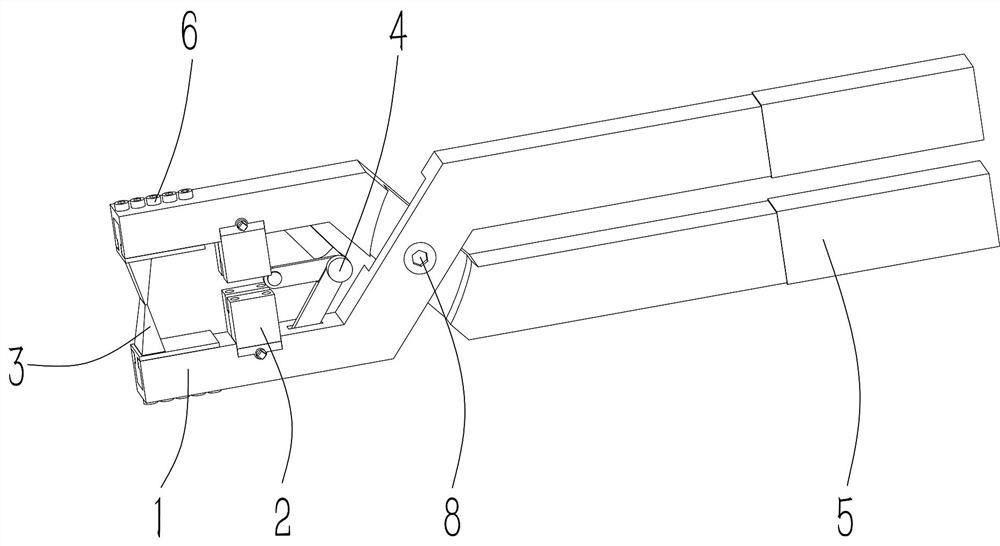

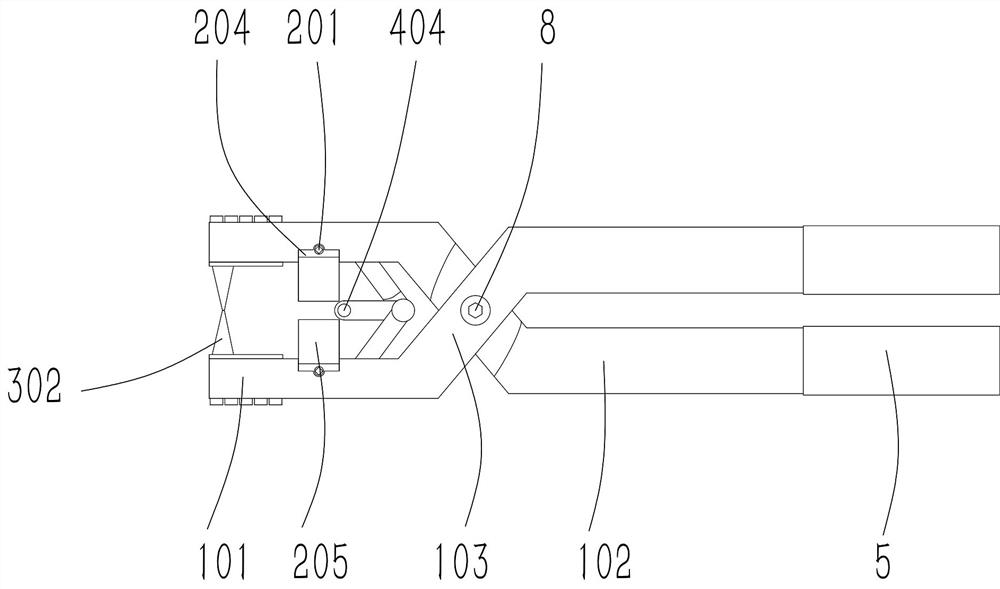

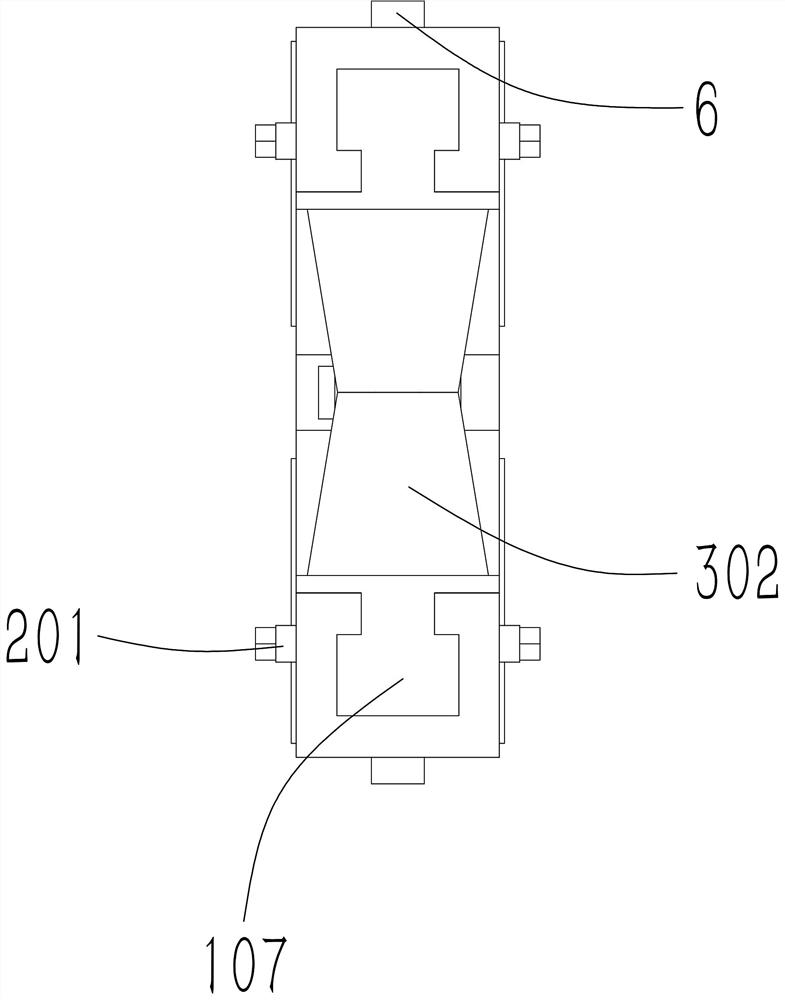

[0039] Such as Figure 1 ~ 13 As shown, an aluminum alloy template pair tapered tool, including two pair of penetration of opposite hinges, including holding head 101, one end of the clamp head 101, pair cutting unit 3, A fixed unit 2 is provided on one side of the unit 3;

[0040] There is also a holding unit 4, and the holding unit 4 is used to hold the tabs to be fixed. From this configuration, so that the fixing unit 2 passes the aluminum alloy template to the tab, two hinged pair of collapse 1 is closed when the two pair of cutting unit 3 is biting each other, and the aluminum alloy template pair shear.

[0041] Preferably, a slide 107 is provided on one side of the clamp head 101, and the upper portion of the slide 107 is penetrated with a plurality of first circular apertures 109, and the panel 3 includes a support plate 301, and the support plate 301 is slid. Inside the slide 107, the upper portion of the support plate 301 is provided with a plurality of threaded holes 303,...

Embodiment 2

[0051] How to use: When used, the user picks up the aluminum alloy template to remove the tool, two hands hold two pair of penetration 1, first align the aluminum alloy template to the pull, pull the aluminum alloy template to the pull A preliminary positioning between the two fixed blocks 205 placed on the fixing unit 2, placing the aluminum alloy template to the pull-pull tabs to the tabs, and put it, and put it, The pull-up fixing hole 11 cards on the round counter 404 of the drive plate 402, and then two hands are close to the compression, and the bias aluminum alloy template pair, so that the two pair of slices 302 of the coloster 1 are bite each other. At the same time, the two fixing units 2 are close to each other, and when the two slice 302 should be paid at the position of the aluminum alloy template to the pull of the tab, finally clamped the two pair of rod 1, and gently press the handle 102 can be cut;

[0052] The position of the slice 302 can be adjusted according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com