Flexible container, method of forming the container, unsealing guide of flexible container, method of filling liquid into container, and liquid

A guide device and a flexible technology, which are applied in the field of flexible containers and their formation, unsealing guide devices for flexible containers, and liquid and liquid encapsulation into flexible containers, which can solve the problem that the clip 220 cannot seal the opening 218, and it is difficult to control the outflow. Direction, operation difficulties and other problems, to achieve the effect of easy handling and storage, and prevent irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

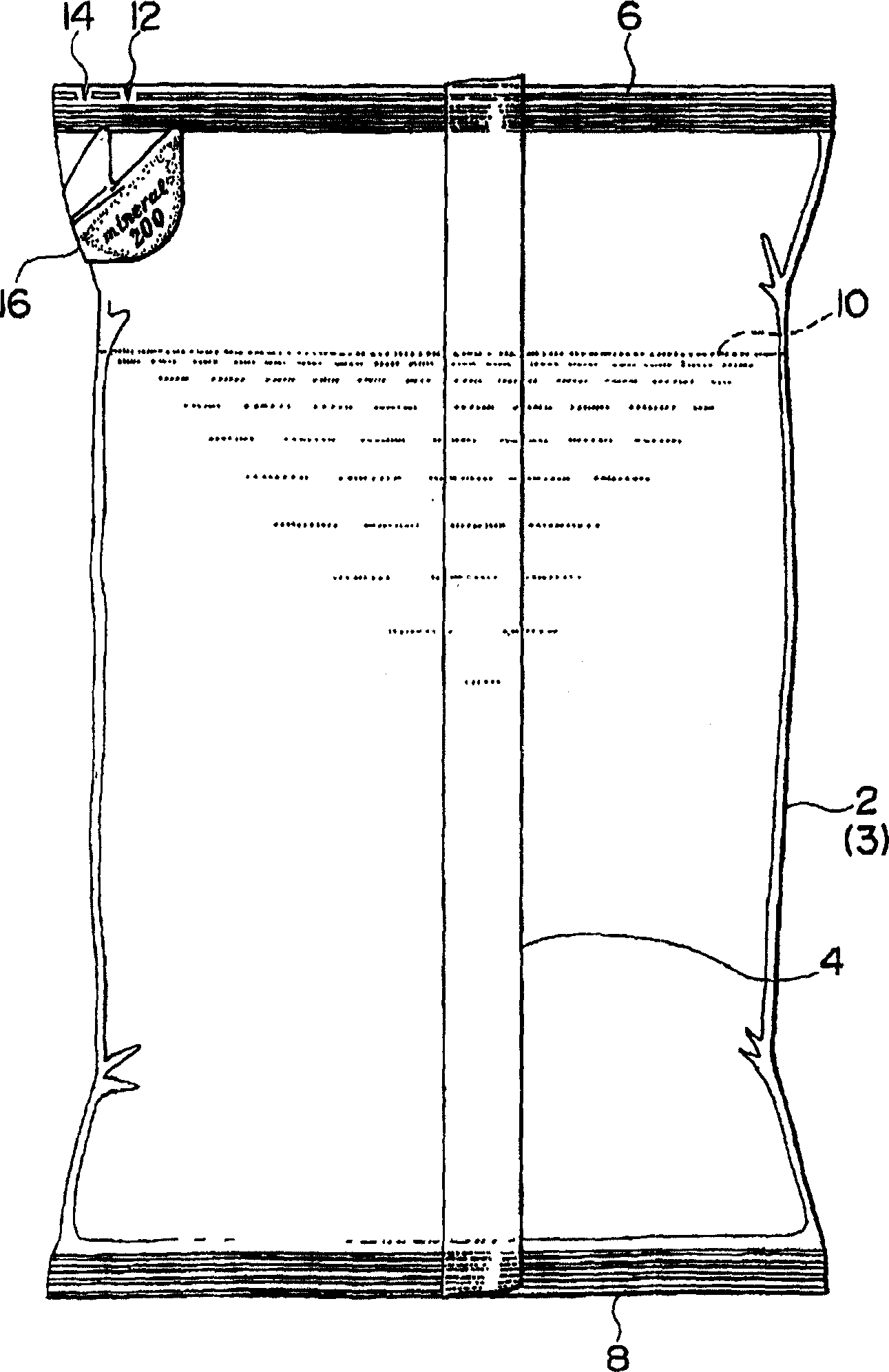

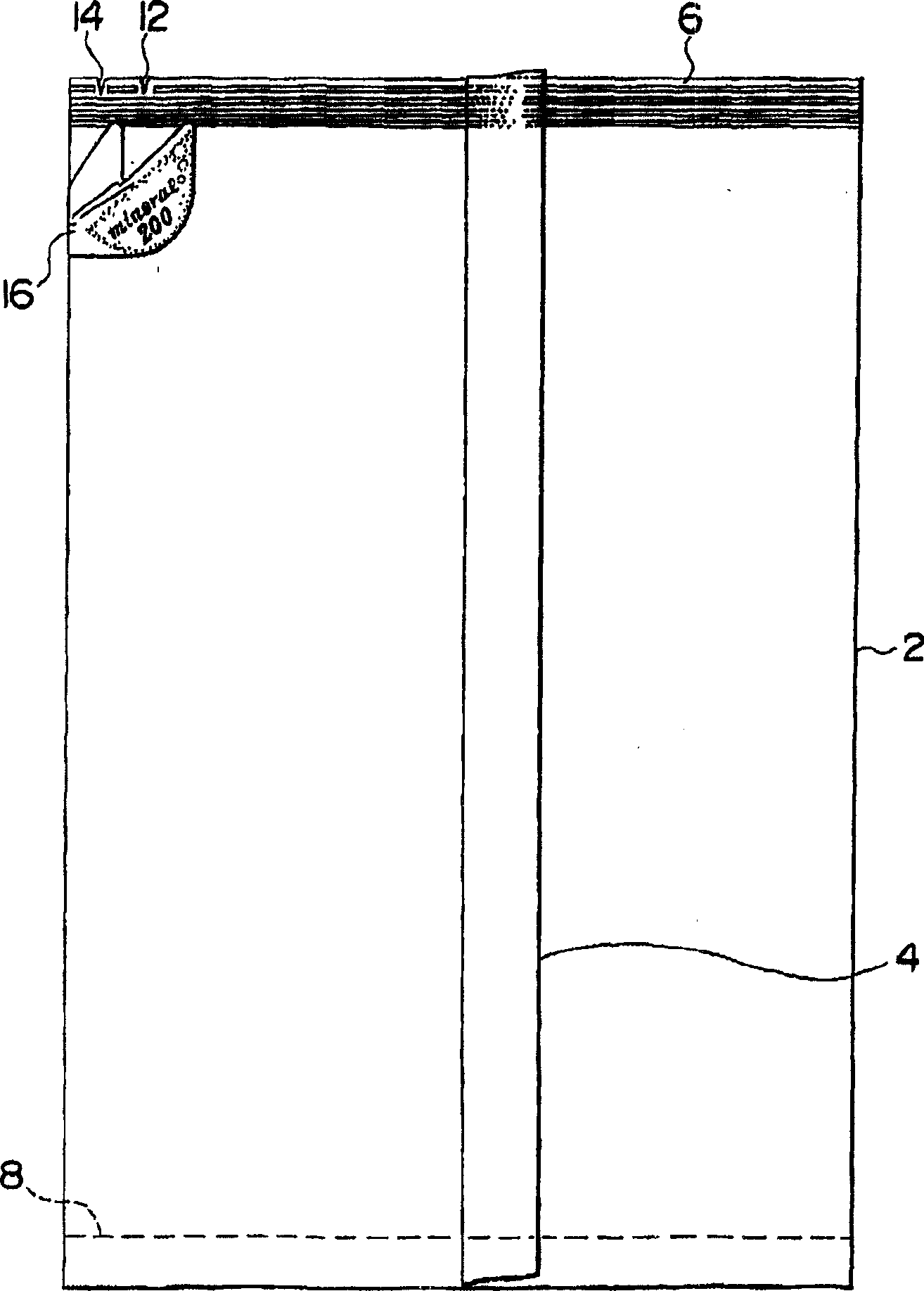

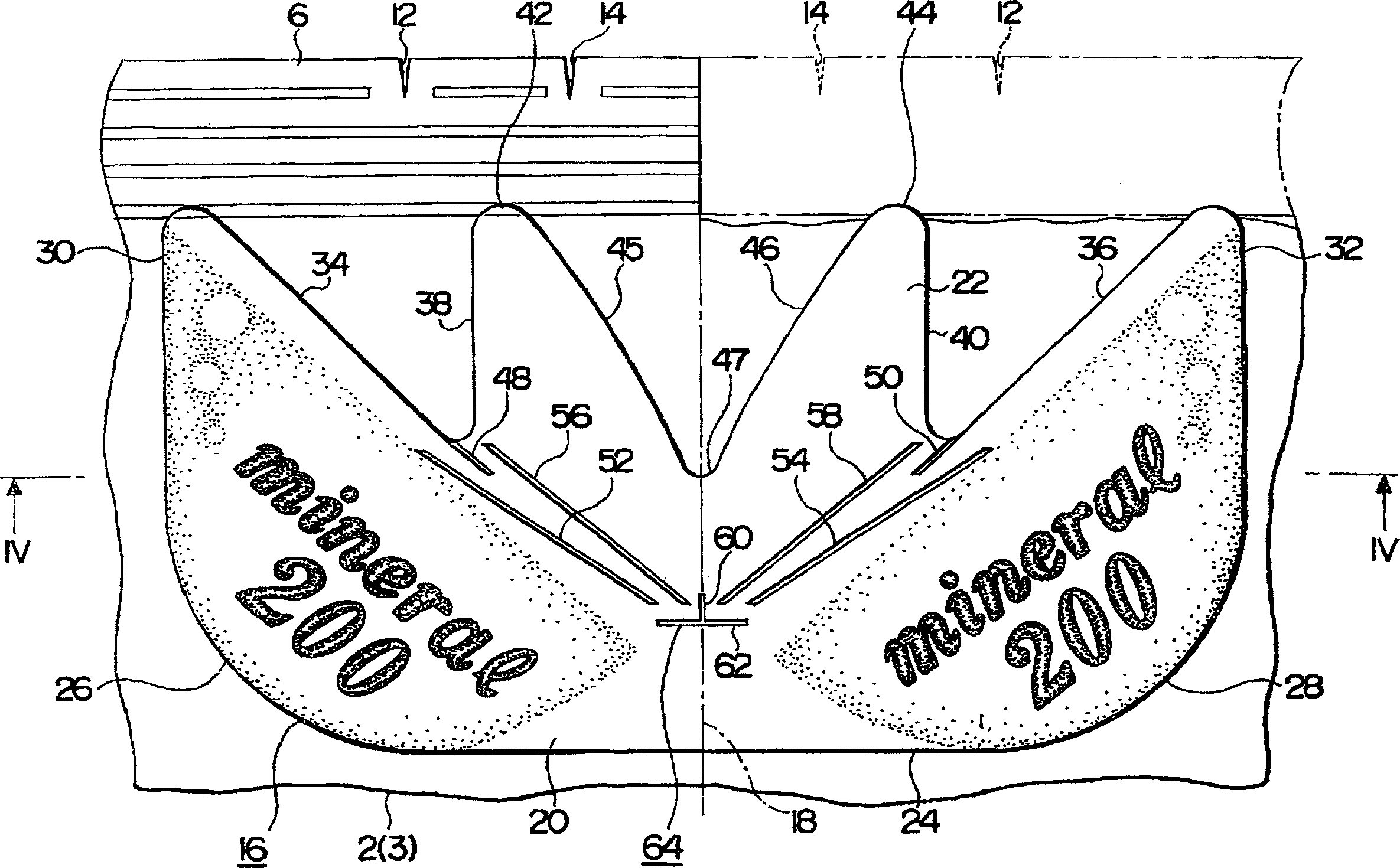

[0047] figure 1 and figure 2 Showing the first embodiment of the flexible container of the present invention, figure 1 Indicates the flexible container after enclosing water, figure 2 Indicates a flexible container before being filled with water. The flexible container has an accommodating portion 2 for storing water, liquid, etc. as a content, and is formed of a sheet-like flexible material 3 such as a synthetic resin film. In the present embodiment, as a mechanism for sealing the housing portion 2 in the longitudinal direction, a central sealing portion 4 is formed, and in a direction perpendicular to the central sealing portion 4, an upper side and a lower side for sealing the housing portion 2 are formed. The top sealing part 6 and the bottom sealing part 8. That is, the housing part 2 forms a sealed space sealed by the three sealing parts 4, 6, and 8, and in the present embodiment, the water 10 is housed therein. figure 2 It shows the storage part 2 when the bot...

no. 2 Embodiment approach

[0072] In addition, in the first embodiment, although the unsealing guide 16 is formed bilaterally symmetrically, when the material constituting the unsealing guide 16 is thicker than the flexible material 3 constituting the housing portion 2, for example, as Figure 10 As in the second embodiment shown, the protrusions 30 and 42 of one side of the unsealing guide 16 are formed asymmetrically so as to avoid thermocompression bonding on the top sealing part 6, and the thermal compression of the top sealing part 6 can be reduced. take on the burden. That is, in this unsealing guide 16, the height of the protruding portion 30 is lower than that of the protruding portion 32, the height of the protruding portion 42 is lower than that of the protruding portion 44, and the inclination angle of the inclined edge portion 34 is gentler than that of the inclined edge portion 36. The inclination angle of the inclined edge portion 45 is also gentler than that of the inclined edge portion 4...

no. 3 Embodiment approach

[0075] In addition, when the material constituting the unsealing guide 16 is thinner than the flexible material 3 constituting the housing portion 2, for example, as Figure 11 As in the third embodiment shown, the inclined edge portions 45, 46 are formed as horizontal edge portions 77, and the protruding portions 42, 44 are formed across the horizontal edge portion 77, and these protruding portions 42, 44 may be sandwiched between in the top seal 6. Furthermore, similarly to the first embodiment, even this structure can obtain a uniform opening by the unsealing guide 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com