Rolled cloth feeding and cutting device

A cloth and cloth feeding technology, which is applied in the field of roll cloth feeding and cutting devices, can solve the problems of wasting cloth, uneven cloth, affecting the appearance, etc., and achieve the effect of reducing labor intensity and avoiding irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

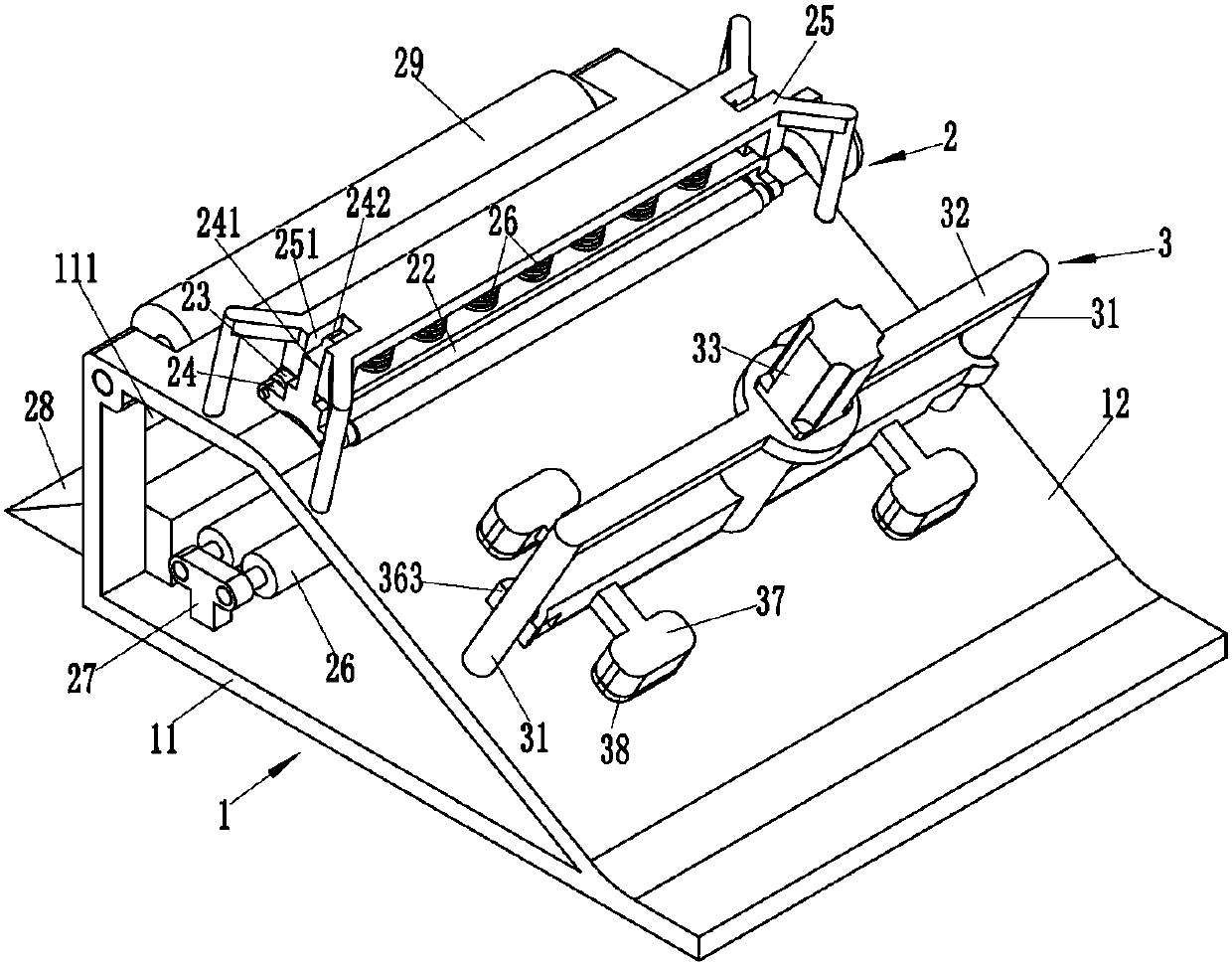

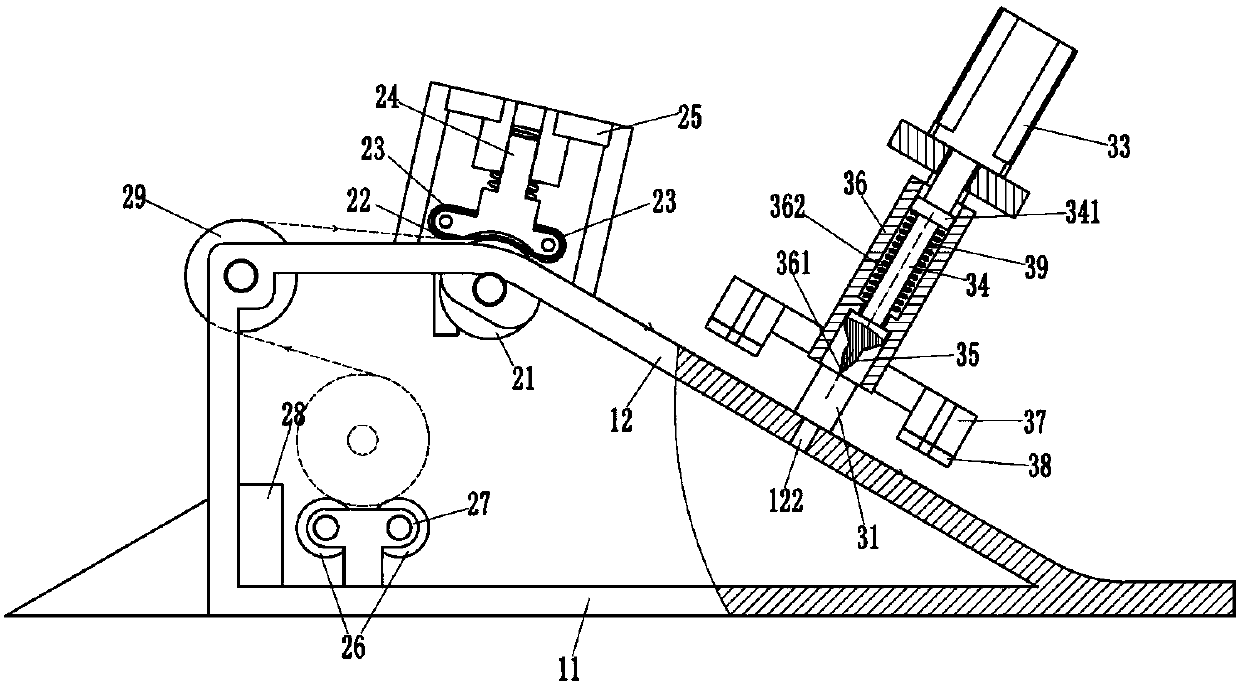

[0013] Examples, see e.g. Figure 1 to Figure 2 As shown, a roll-shaped cloth feeding and cutting device includes a frame 1, and the frame 1 includes a right-angle plate 11 and a folding plate 12 fixed on the right-angle plate 11, and the bending part of the folding plate 12 is formed with a long groove. The bending part of the folding plate 12 is provided with a cloth feeding device 2, and the inclined surface of the folding board 12 is provided with a cloth cutting device 3. The cloth feeding device 2 includes a driving roller 21 hinged in a long groove, and the driving roller 21 wears The rear side wall of the overlong groove is fixed with a motor, and the top of the driving roller 21 is provided with an extruding belt 22, and the extruding belt 22 is tensioned on the two extruding rollers 23, and the two ends of the two extruding rollers 23 are hinged on the floating On the bracket 24, the floating bracket 24 is sleeved on the fixed bracket 25, and the fixed bracket 25 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com