Silicon chip cutting device

A silicon wafer cutting and cutting knife technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of silicon wafer damage, waste, low cutting efficiency, etc., to avoid offset and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

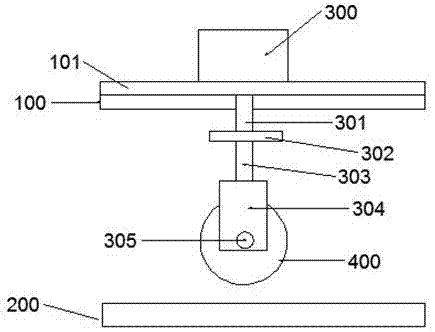

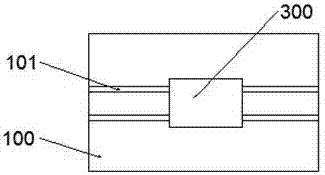

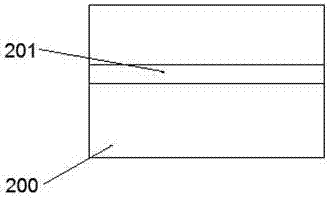

[0016] as attached Figure 1~3 As shown, the silicon wafer cutting device includes an upper support 100, a fixed table 200, a cylinder 300, and a cutting knife 400;

[0017] The upper bracket 100 is located above the fixed table 200, and the upper bracket 100 is provided with two slide rails 101, which are parallel to each other between the two slide rails 101, and the slide rails 101 and the fixed table 200 parallel to each other. The air cylinder 300 is horizontally arranged between the two slide rails 101, the telescopic end 301 of the air cylinder 300 is longitudinally arranged below the upper bracket 100, and the end of the telescopic end 301 close to the fixed table 200 is horizontally A push plate 302 is provided, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com