Can lid packaging machine

A packaging machine and can lid technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of irregular packaging, low work efficiency, waste of labor, etc., to avoid irregular packaging, save labor costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

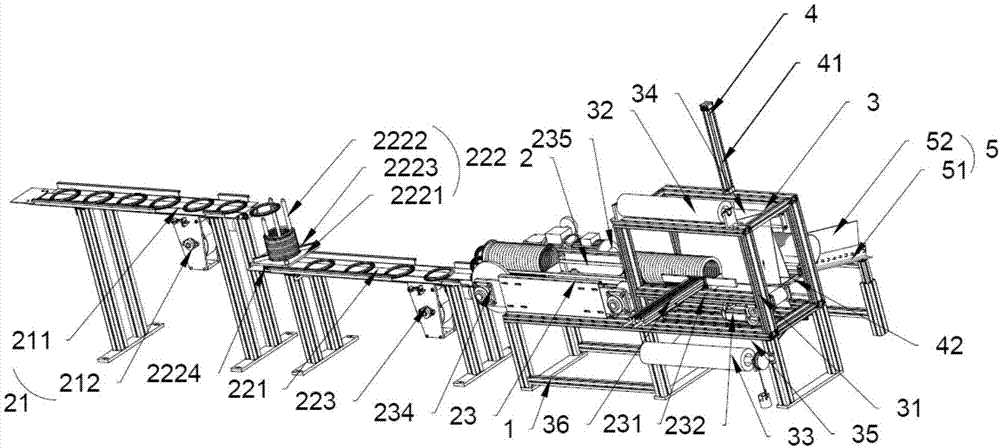

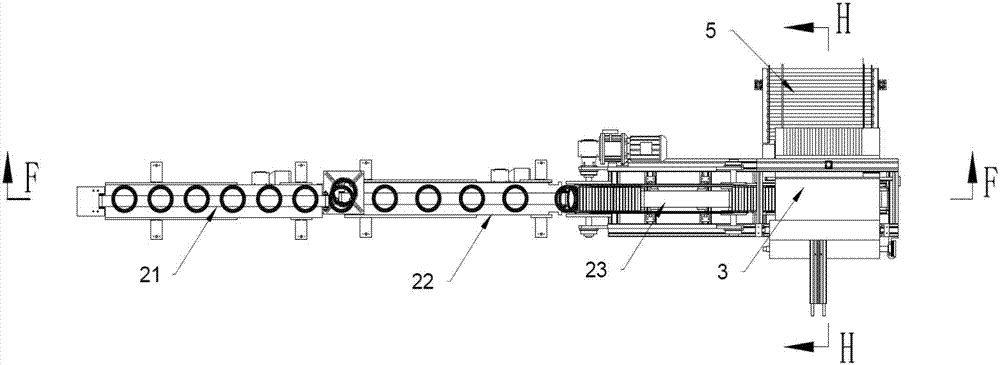

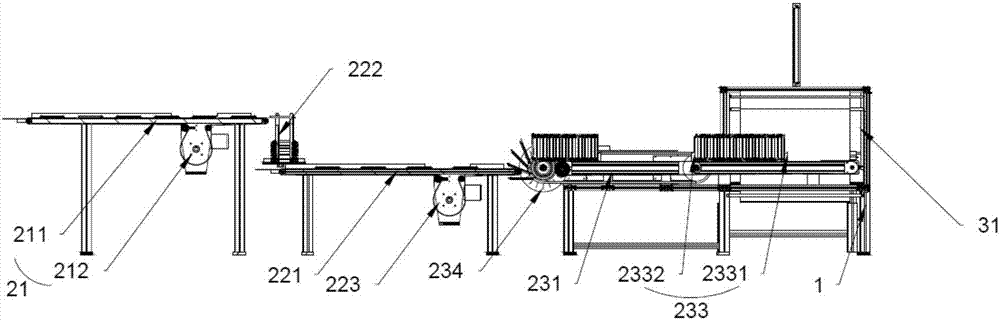

[0023] Please also see Figure 1 to Figure 5 , figure 1 It is an oblique view of the embodiment of the can lid packaging machine of the present invention; image 3 for figure 2 The sectional view along the F-F direction is shown; Figure 4 for figure 2 The sectional view along the H-H direction is shown; Figure 5 It is a side view of the embodiment of the can lid packaging machine of the present invention. The can lid packaging machine includes a frame 1 , a conveying device 2 arranged on the frame, a packaging device 3 , a heat cutting device 4 and a pre-tensioning device 5 . The conveying device 2 is used to convey the can ends on the punching line to the packaging device 3; the packaging device 3 is used to heat-seal the can ends through the shrink film; the thermal cutting device 4 is used to shrink the can ends The film is cut off, and then the packaging can end is obtained. The pre-tightening device 5 is used to pre-tighten the packaging can lid and transport i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com