Plane framework supporting structure capable of steel charge expansion

An inflatable deployment and support structure technology, which is applied to the support structure of photovoltaic modules, electrical components, antenna supports/mounting devices, etc., can solve the problems of poor reliability of deployment, heavy overall weight, and low folding efficiency, and achieve light overall weight , simple structure and high folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

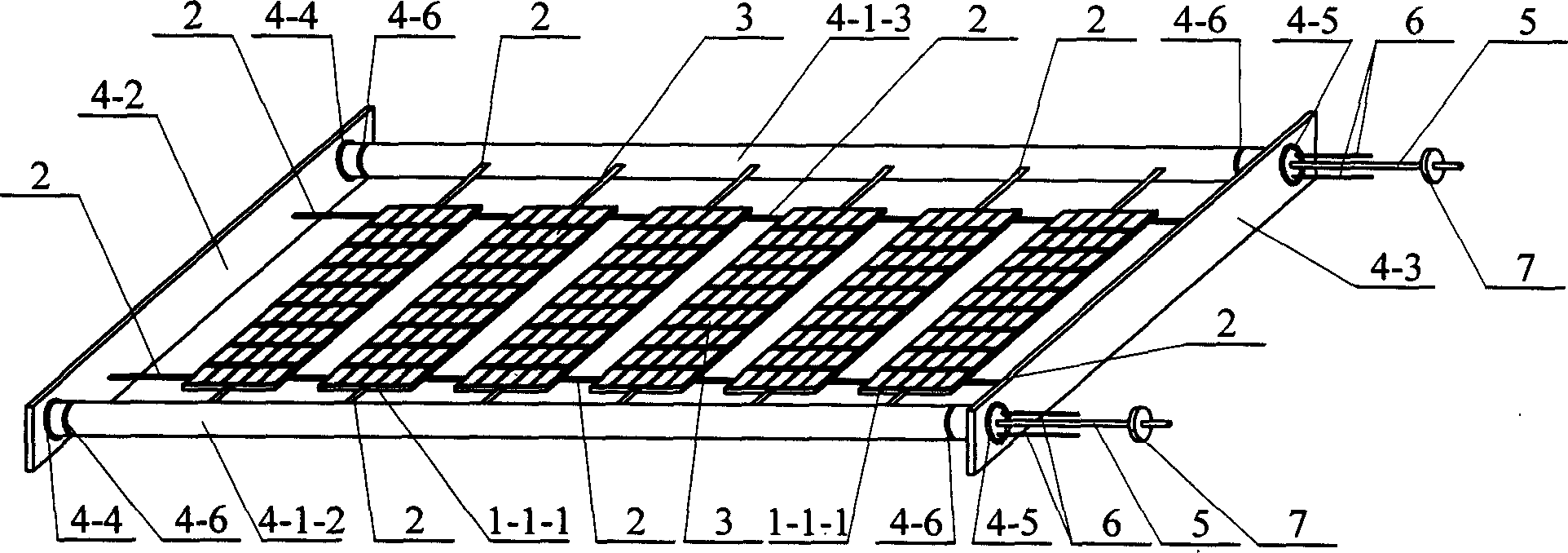

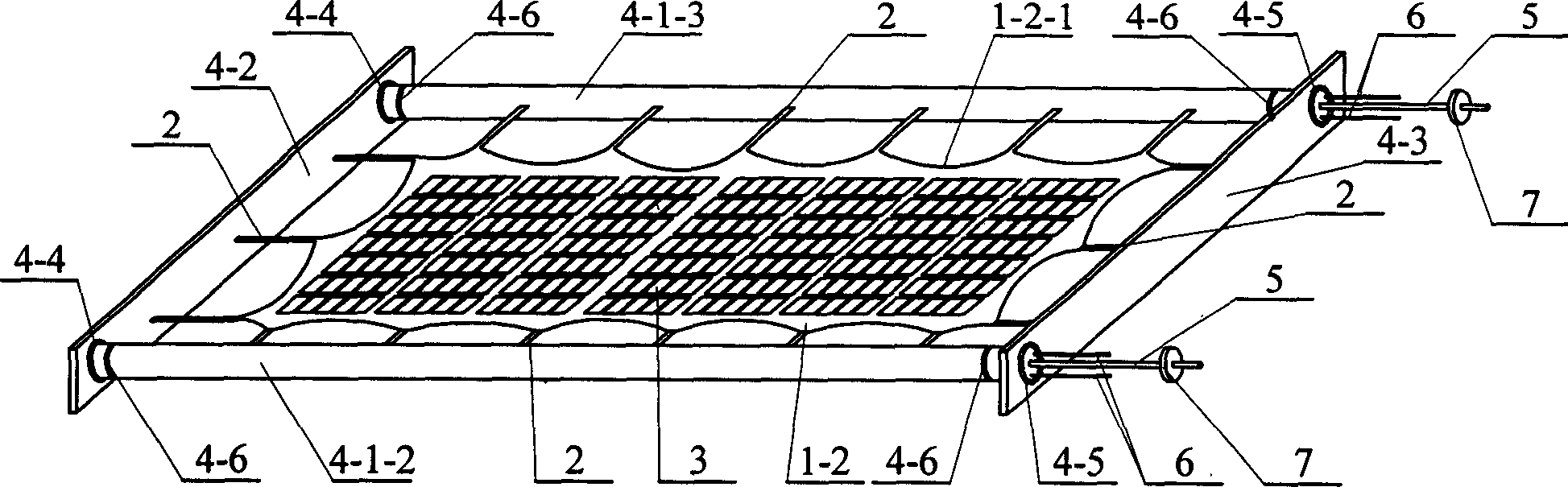

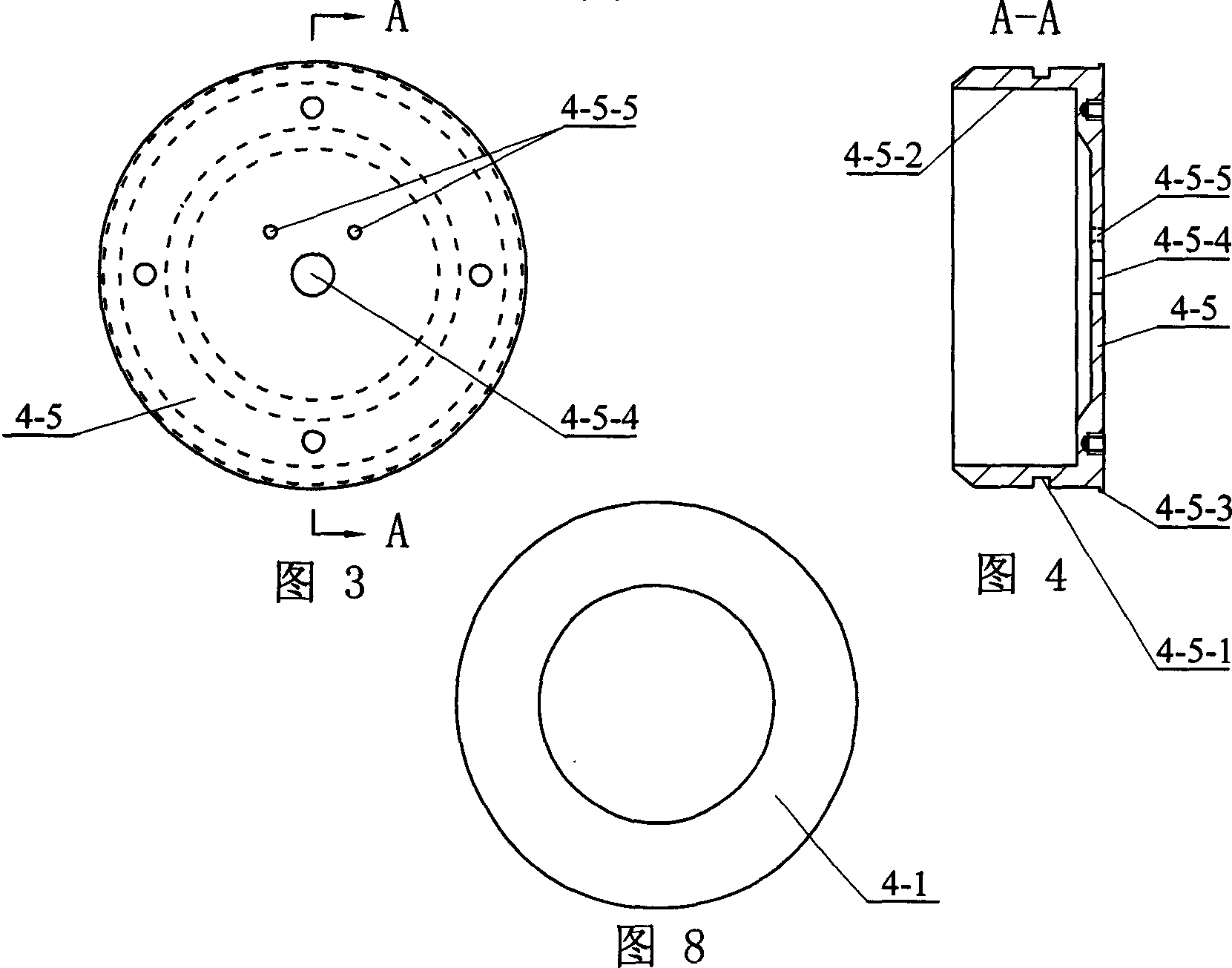

[0006] Specific implementation mode one: combine figure 1 , figure 2 , Figure 7, Figure 9 Describe this embodiment, this embodiment is made up of base plate, lace 2, patch layer 3, frame 4 that can be rigidized and inflated to expand, inflation pipeline 5, wire 6, control valve 7; Described frame 4 is equipped with along frame The substrate placed vertically, the substrate and the frame 4 are fixedly connected by a tie 2; the upper end of the substrate has a patch layer 3, and the left end of the wire 6 is installed on the support tube 4 on the frame 4, which can be rigidified and inflated -1 and is connected with the electric heating layer 4-1-1 of the support tube 4-1, the left end of the inflation pipeline 5 is installed in the support tube 4-1, and the control valve 7 is installed on the inflation pipeline 5; The substrate is a rigid substrate or a flexible substrate 1-2.

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 , Figure 9 Describe this embodiment, the rigid substrate of this embodiment is composed of a group of rigid substrate units 1-1-1 placed in parallel, between two adjacent rigid substrate units 1-1-1 and the rigid substrate unit 1-1-1 It is fixedly connected with the frame 4 through a tether 2. The base plate is composed of a group of rigid base plate units 1-1-1, and this structure can keep the base plate flat and easy to fold. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 2 , Figure 9 To illustrate this embodiment, the flexible substrate 1-2 of this embodiment is composed of at least one layer of polymer film or at least one layer of resin pre-impregnated fiber fabric, and the flexible substrate 1-2 is fixedly connected to the frame 4 through a tie 2 . The flexible substrate 1-2 has the advantages of simple structure, light weight, high folding efficiency and small folding volume. In this embodiment, in order to maintain the flatness of the flexible substrate 1-2, the outer periphery of the flexible substrate 1-2 is connected to the tether 2 in the form of a catenary 1-2-1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com