Multi-layer cavity type inflating expansion protection mechanism

A technology of inflatable deployment and protective mechanism, which is applied in the direction of aerospace vehicle anti-meteorite devices, aerospace safety/emergency devices, etc. It can solve the problems of low folding efficiency, low deployment reliability and small size of space debris impact damage, and achieve inflatable deployment. The process is stable, the protection effect is good, and the emission volume is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: This embodiment will be described with reference to FIGS. 1 to 7 and 19. This embodiment includes an inflatable support frame to be stiffened 1, at least two layers of protective screens, at least three inflatable support tubes to be stiffened 2, and at least three supports Tube inflation pipe 3, a main inflation pipe 4, at least one outlet pipe 5, at least three second electromagnetic inflation valves 6, at least six throat clamps 7 and at least six second end caps 8; the adjacent two The peripheral parts of the layers of protective screens are bonded together to form at least two layers of cavity-type inflatable expansion protection screens to be stiffened, and the at least two layers of cavity-type inflatable expansion protection screens to be stiffened are arranged on the inflatable support frame to be stiffened 1 and connected with the inflatable support frame 1 to be stiffened, one end of the main inflation tube 4 is installed in at least two...

specific Embodiment approach 2

[0010] Specific implementation mode two: the number of layers of the cavity-type inflatable protective screen to be rigidified in this embodiment is 2-20 layers, and the thickness of each layer of the cavity-type inflatable protective screen to be rigidified is 0.1cm- 5cm, and the diameter of the cavity-type inflatable deployment protective screen to be rigidified is 0.5m-10m. Such setting can resist the impact damage of space debris. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

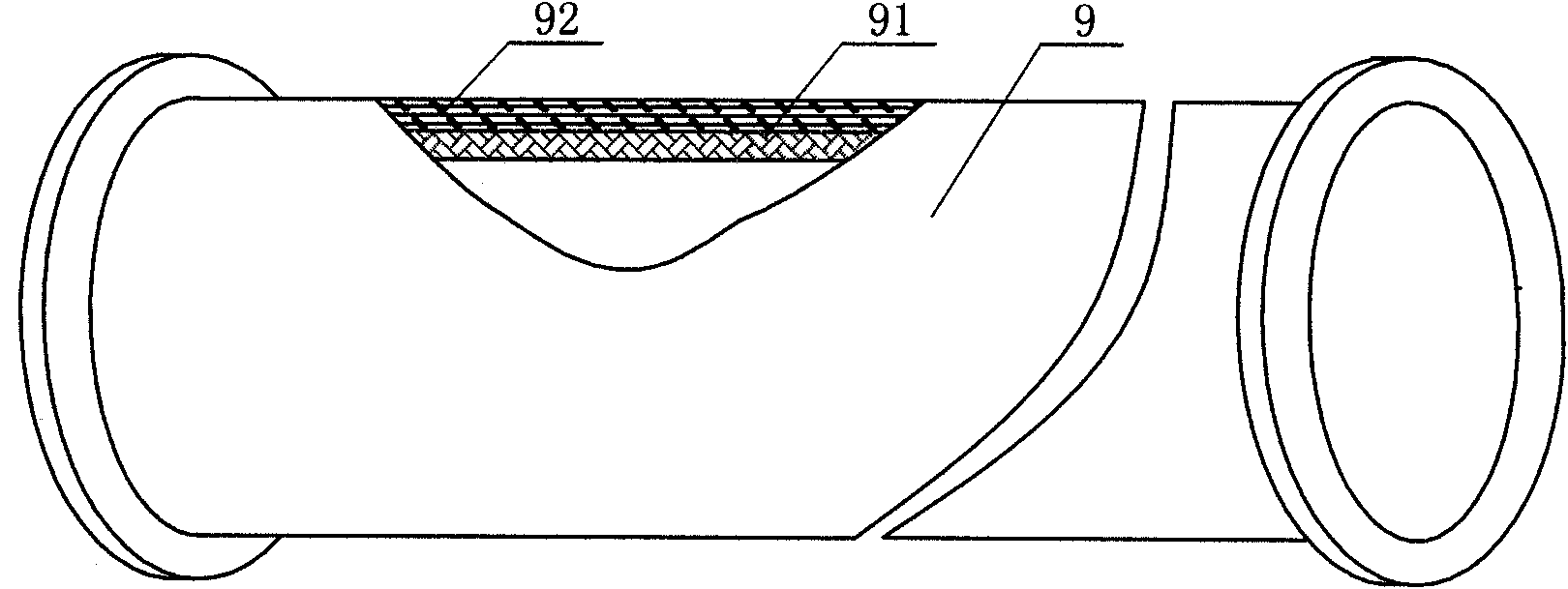

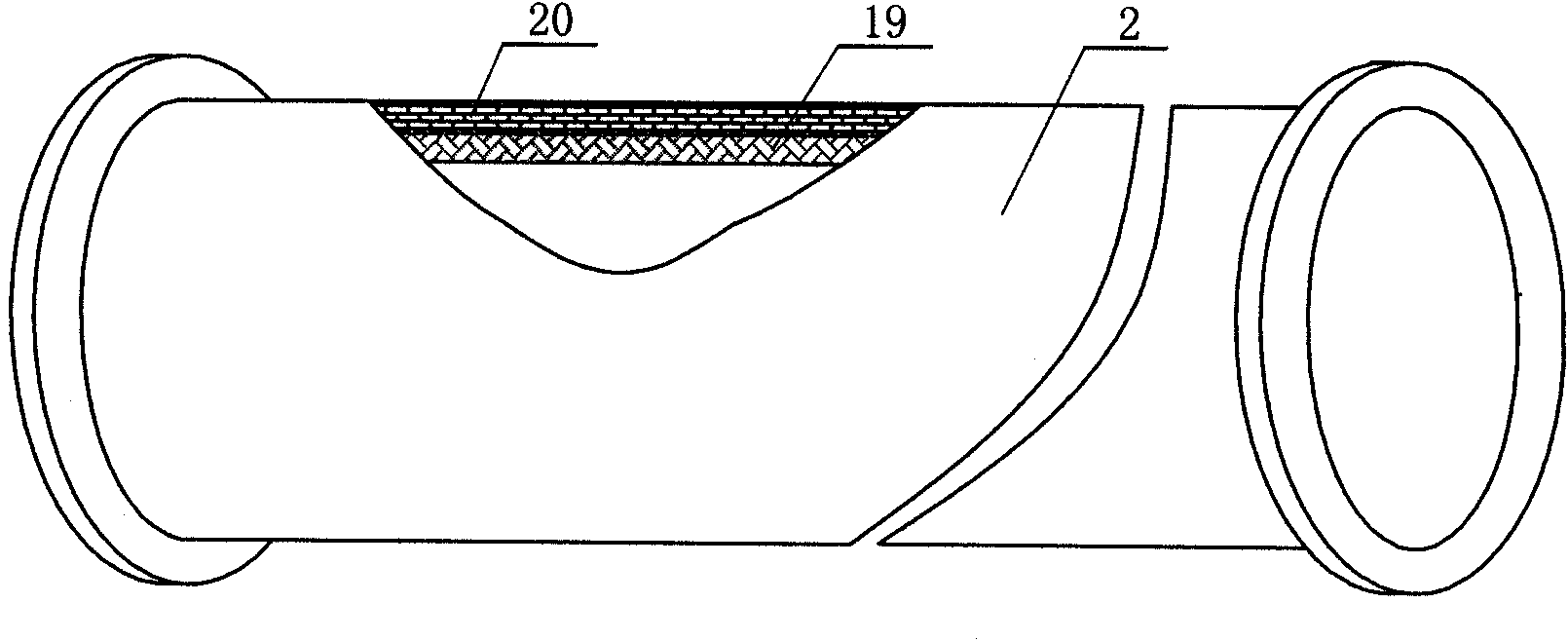

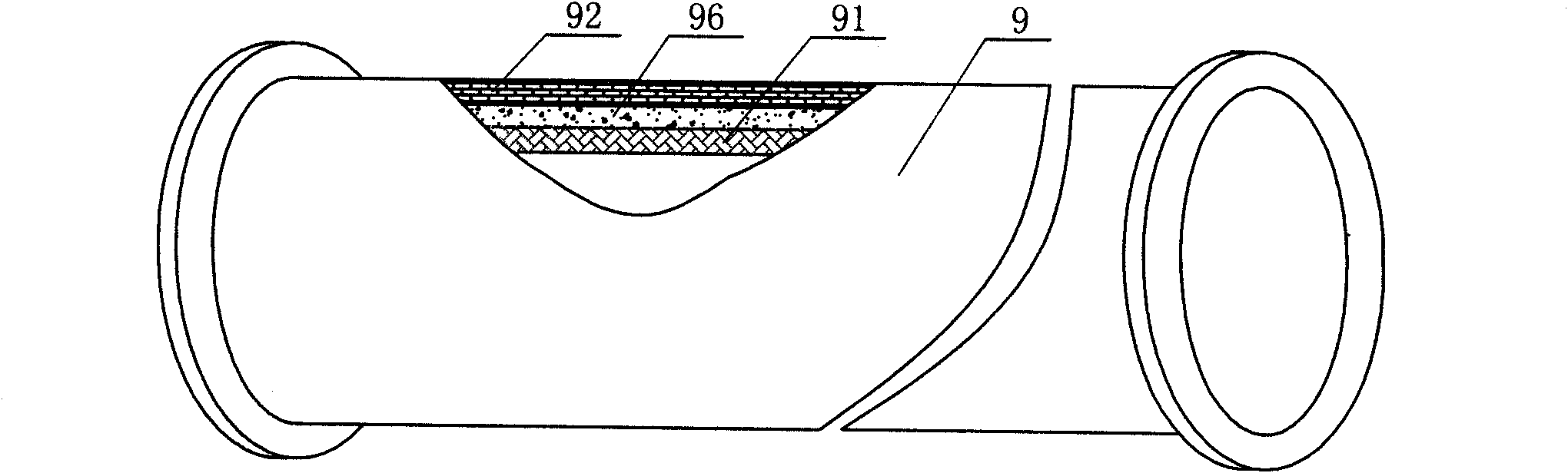

[0011] Specific Embodiment Three: This embodiment is described in conjunction with Fig. 1, Fig. 4, Fig. 9 and Fig. 10. The cavity-type inflatable deployment protective screen to be rigidized in this embodiment is a flexible cavity-type inflatable deployment protection screen to be rigidified 16. Each layer of the flexible cavity-type inflatable inflatable protective screen 16 to be stiffened includes a gas isolation layer 17 and a solidified layer 18 that are stacked and fixed together; each tube of the inflatable support tube 2 to be stiffened The wall includes a gas barrier layer 19 and a thermosetting layer 20 affixed together from the inside to the outside, and the tube wall of each inflatable tube 9 to be rigidified includes a barrier layer 91 and a thermosetting layer affixed together from the inside to the outside. Layer 92, the material for making the cured layer 18, the thermosetting layer 20 and the thermosetting layer 92 is a thermosetting resin prepreg fabric, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com