Space fragment and micrometeoroid impact resistant protection mechanism capable of inflating and expanding on rails

An inflatable deployment and protection mechanism technology, which is applied in the directions of aerospace vehicle anti-meteorite devices, aerospace safety/emergency devices, etc., can solve the problems of difficulty in achieving the folding efficiency of protective screens, difficulty in building multi-layer protection, and low deployment reliability. High deployment efficiency, good deployment reliability and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

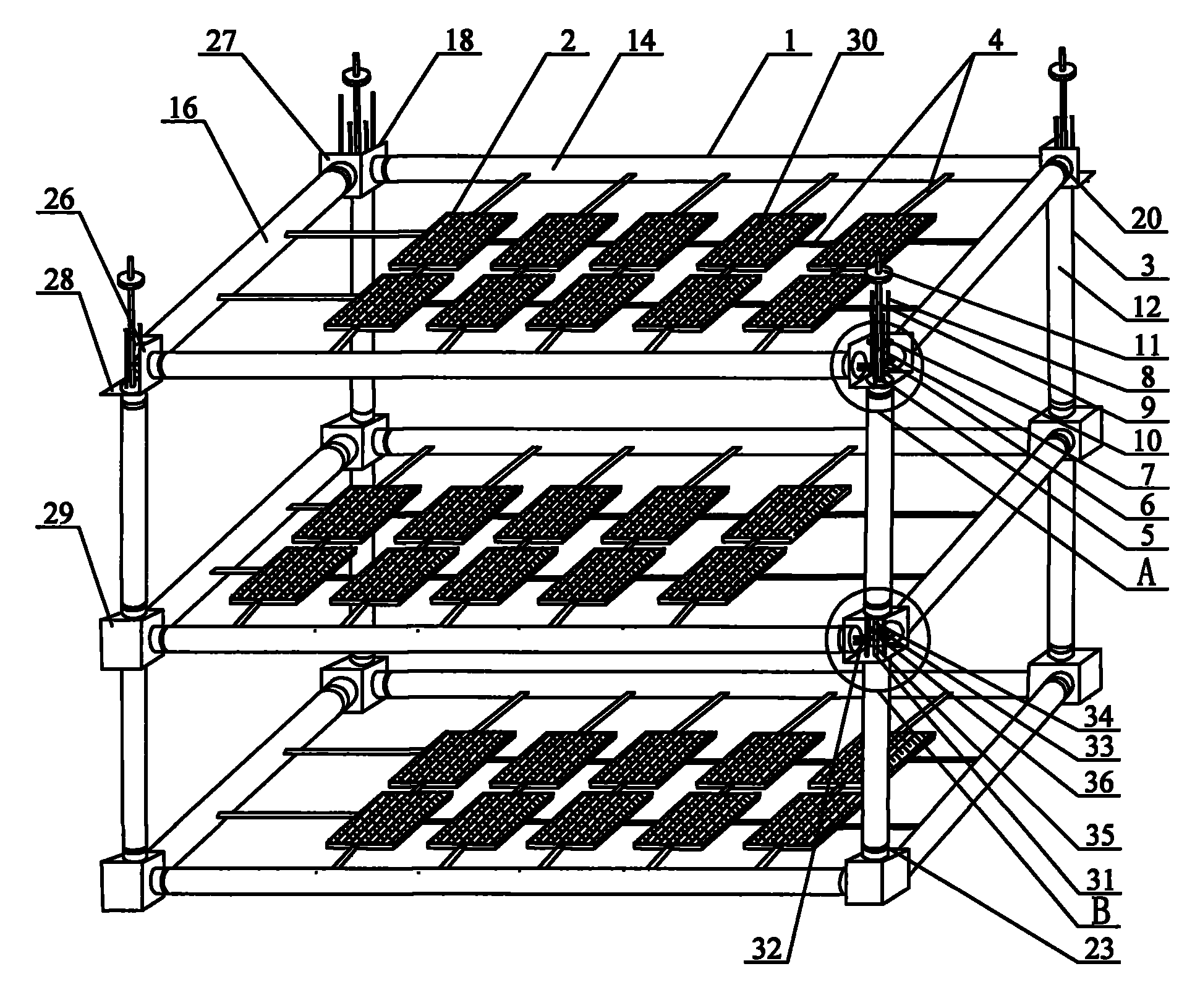

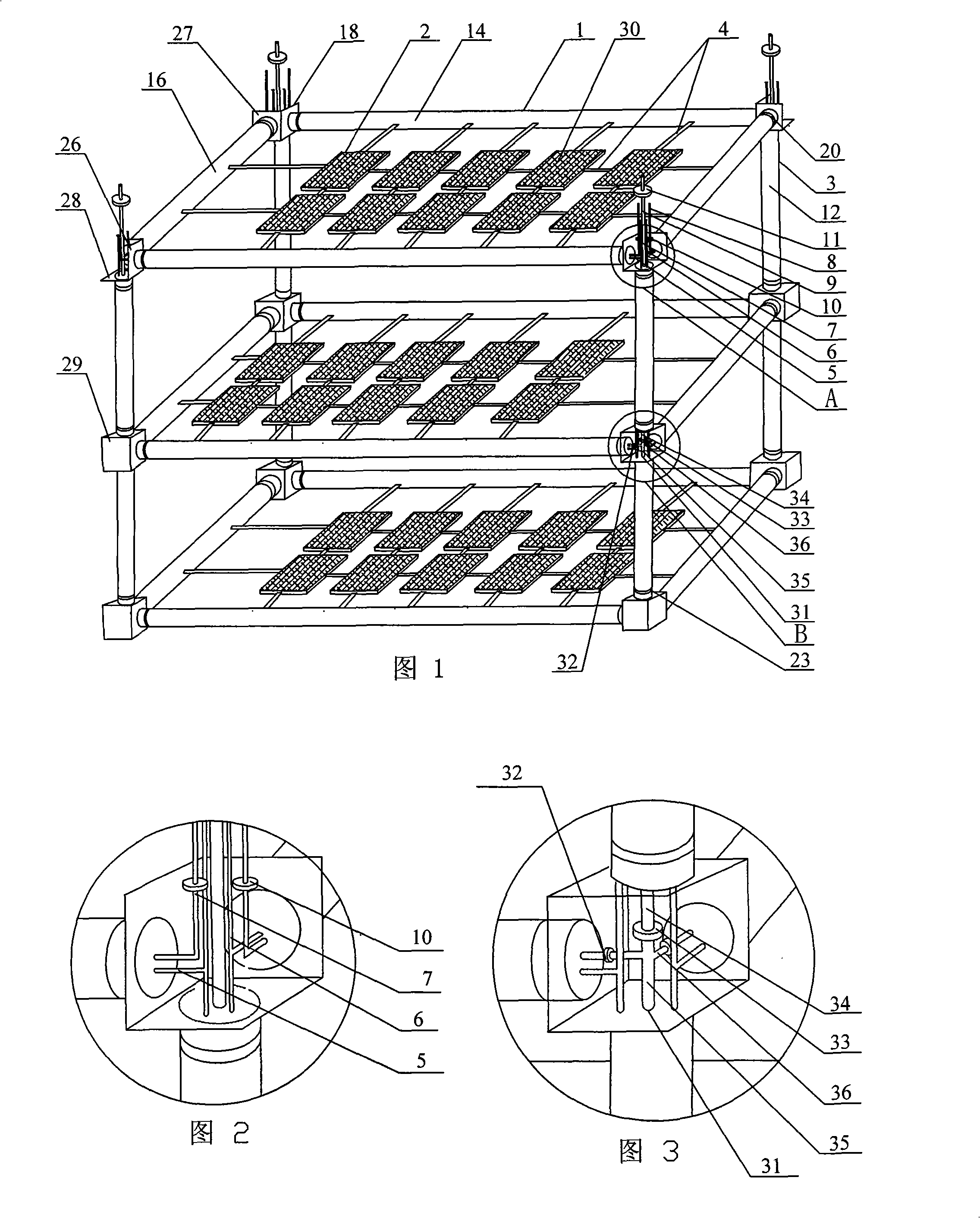

[0007] Specific Embodiment 1: This embodiment is described with reference to FIGS. 1 to 4 and FIGS. 9 to 11 . An inflatable deployment support riser assembly 3, a plurality of ties 4, at least two horizontal wires 5, four pairs of vertical parallel wires 6, two first inflatable tubes 7, two second inflatable tubes 8, four vertical Straight inflatable pipe 9, four horizontal inflatable control valves 10 and four control valves 11; the at least two layers of stiffened inflatable unfolded planar frames 1 are facing up and down and arranged in parallel, and the adjacent two layers of stiffened inflatable unfolded planar frames The four corner ends of 1 are connected by four inflatable deployment support riser assemblies 3 to form an airtight inflatable deployment support frame, and a protective screen 2 is arranged in each layer of rigid inflatable deployment plane frame 1, and each layer Each protective screen 2 is connected with the corresponding stiffened inflatable unfolded pl...

specific Embodiment approach 2

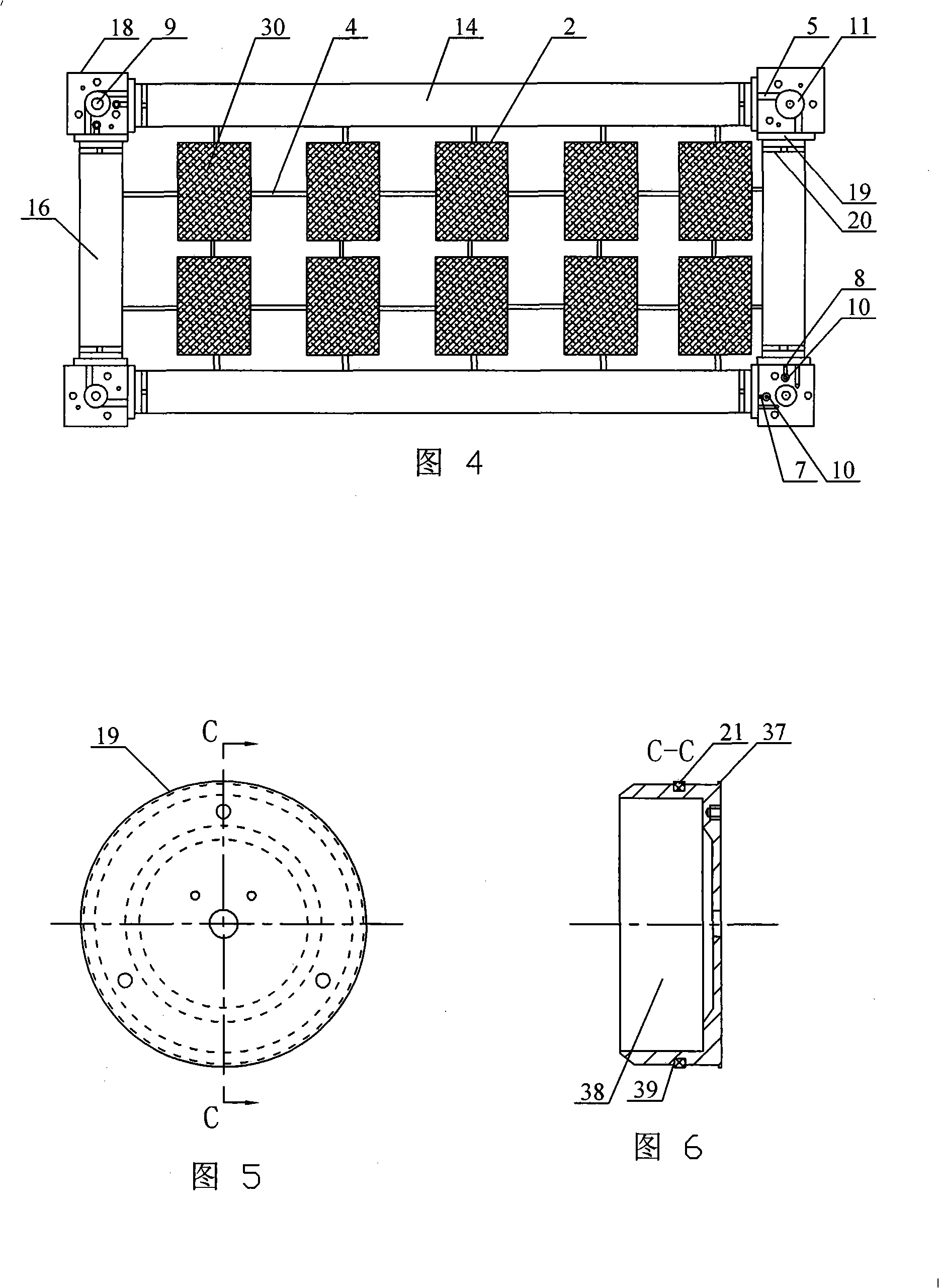

[0008] Specific Embodiment 2: This embodiment will be described with reference to FIGS. 1 to 4 , 5 and 6. Each layer of rigid inflatable and unfoldable planar frame 1 in this embodiment consists of two rigid inflatable and expandable long support tubes 14, two One stiffenable inflatable expandable short support tube 16, four connectors 18, eight end caps 19, eight clamps 20 and eight sealing rubber rings 21; the two rigidizable inflatable expandable long support tubes 14 and two stiffenable inflatable and expandable short support tubes 16 are set opposite to each other to form a rectangular frame, each corner of the rectangular frame is respectively provided with a connecting piece 18, each of the rigidizable inflatable expandable long support tubes An end cover 19 is installed respectively in the two ends of 14 and in the two ends of each stiffenable inflatable deployment short support tube 16, and the end cover 19 is connected with the stiffenable inflatable through the seali...

specific Embodiment approach 3

[0009] Specific Embodiment Three: This embodiment is described with reference to Figs. 1 to 4, Fig. 7 and Fig. 8. Each inflatable deployment support riser assembly 3 in this embodiment consists of a rigidizable inflatable deployment support riser 12 and two connection plates. 22. Two throat hoops 23 and two sealing rubber rings 24; each of the two ends of each stiffened inflatable support standpipe 12 is equipped with a connecting plate 22, and the connecting plate 22 is installed on its outer wall The sealing rubber ring 24 is airtightly connected with the inner wall of the stiffening inflatable support standpipe 12, and a hose clamp 23 is respectively installed on the outer wall of each stiffenable inflatable spread support standpipe 12 two ends, and each can be rigidified inflatable expand support standpipe 12. The two ends of the support standpipe 12 are fixedly connected to the connection plate 22 through the throat clamp 23 respectively, and the two ends of each rigidizab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com