Rapidly-controlled aeration releasing mechanism

A release mechanism and fast technology, applied in projectiles, self-propelled projectiles, offensive equipment, etc., can solve the problems of low folding efficiency and high weight, and achieve the effects of rapid unfolding, small size, fast and controllable unfolding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

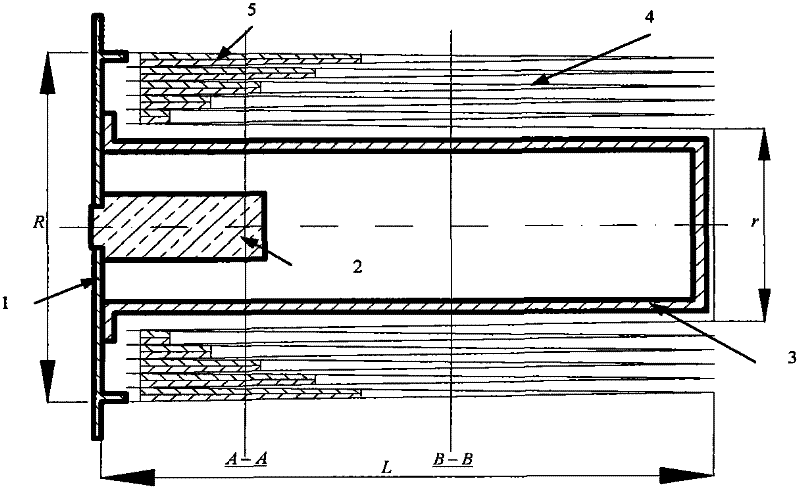

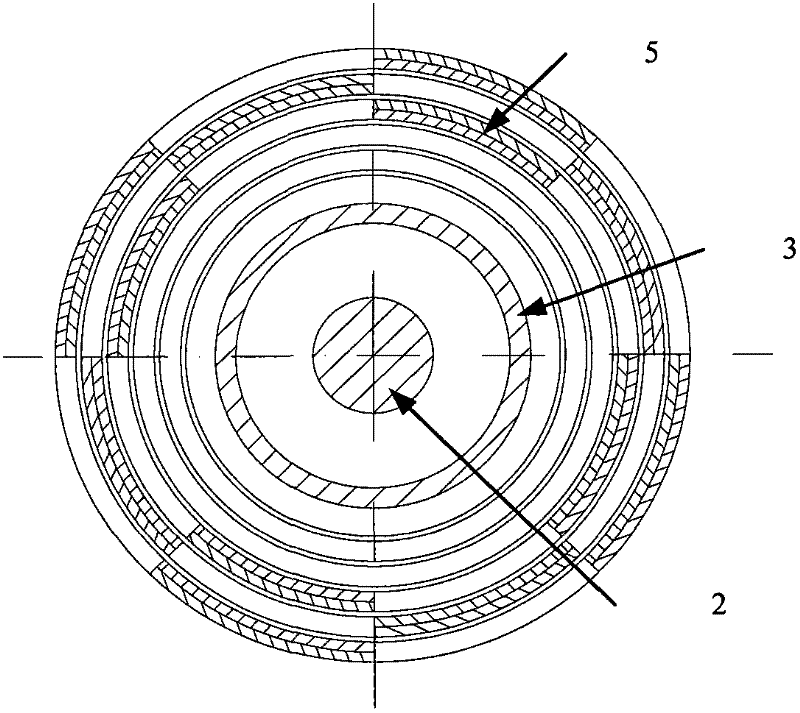

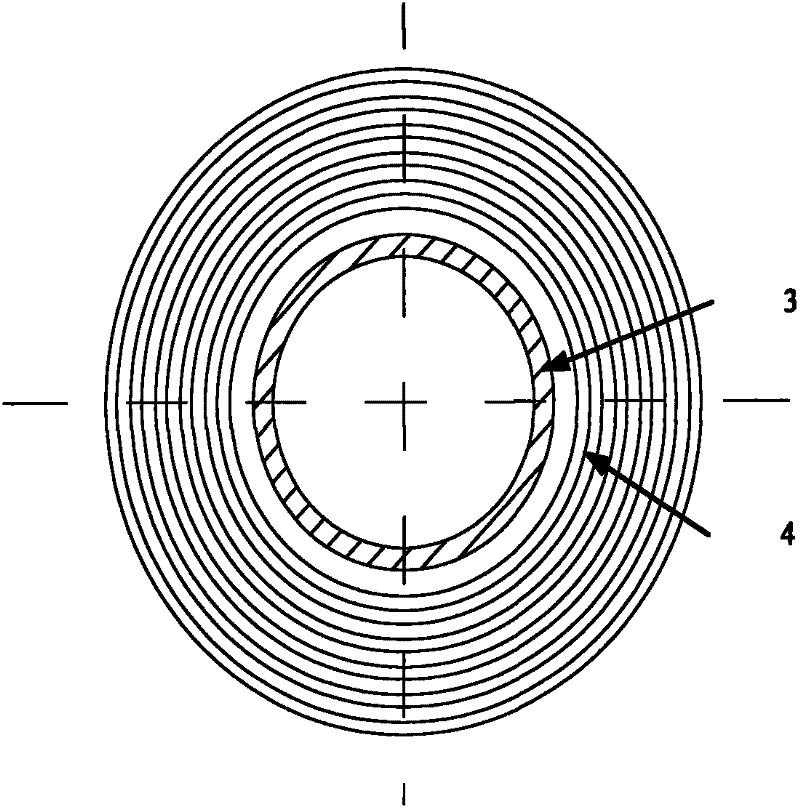

[0024] The invention provides a fast and controllable inflation release mechanism, which is mainly composed of five parts such as an end cover, a gas generator, a guide cylinder, a film tube and a sticky buckle. This mechanism mainly unfolds the folded film tube through the gas generated by the gas generator. Its working process is as follows. When it needs to be deployed, an electrical signal is sent to the gas generator from the outside. Under the action of the electrical signal, the gas-generating agent in the gas generator is detonated, and a large amount of gas is generated instantaneously. The gas first enters the guide cylinder. The other end of the guide tube has a small air outlet, such as Figure 5 As shown, the gas flows out through the air outlet and directly acts on the expansion end of the inflatable tube. Under the action of air pressure, the inflatable tube expands outwards along the guide tube in sequence. The expansion process is as follows: Figure 6 shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com