300-foot self-elevating drilling platform spud leg and shoe segmented carrying method

A drilling platform leg and jack-up technology, which is applied in the field of offshore engineering and ship construction, can solve problems such as undiscovered, and achieve the effects of controlling welding deformation, superior space conditions, and improving welding quality and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

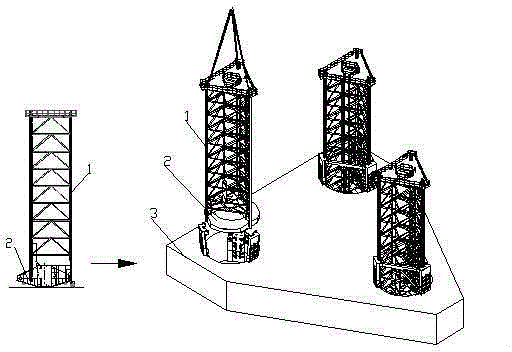

[0040] Such as figure 1 As shown, the present invention discloses a stepwise loading method of pile legs and pile boots for a 300-foot jack-up drilling platform. The method is to first fold the first section 1 of the pile legs and the pile boots 2 on the slideway of the offshore platform. Then, the first section of the pile leg is hoisted integrally into the enclosed shaft 3 sections for positioning.

[0041] Such as figure 2 As shown, the specific steps of the above-mentioned pile leg and pile shoe mounting method are as follows:

[0042] (1) The first section of the pile leg and the pile shoe are closed in sections:

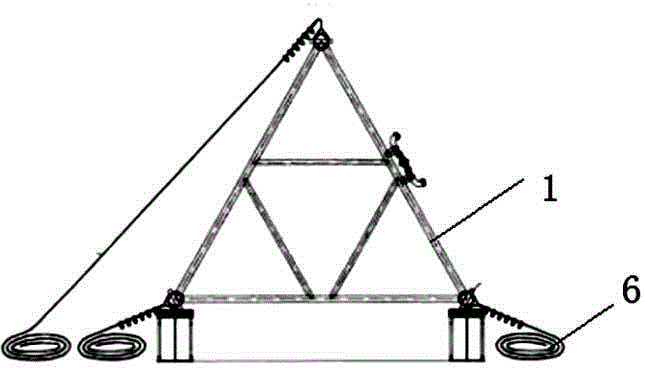

[0043] S1. Arrangement of pile shoe tire frame: such as figure 2 As shown, the pile shoes 2 are placed on the offshore platform 4 in sections, and a tire frame 5 is arranged at the bottom of the pile shoes 2, and then the levelness of the pile shoes 2 is measured and adjusted to keep the pile shoes level;

[0044] S2, the first section of the leg is turned over to in...

Embodiment 2

[0053] Such as Picture 9 As shown, this embodiment is on the basis of embodiment 1. In step S1, the level of the pile shoe is adjusted, and the level of the pile shoe section is measured based on the foreign punch hole 12 in the pile shoe section workshop. Degree, and ensure the levelness ≤ 2mm.

[0054] In this embodiment, the levelness of the pile shoe sections is measured by the foreign punching eyes on the pile shoe sections, and the levelness is guaranteed to be ≤ 2mm, which ensures the accuracy of the first section of the subsequent pile leg and the pile shoe.

Embodiment 3

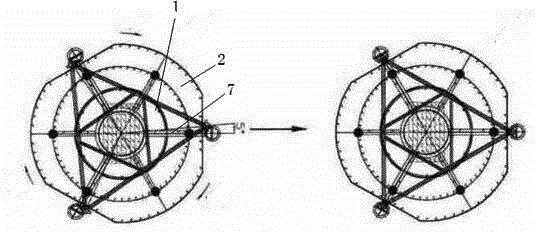

[0056] Such as Picture 10 As shown, this embodiment is based on embodiment 1 or embodiment 2, in step S3, in step S3, the hoisting of the first section 1 of the pile leg is staggered by 5° from the vertical plate 7 of the pile shoe segment, and the first section of the pile leg is rotated to view the pile shoe Adjust the assembly clearance between the top and bottom of the vertical plate and the rack plate. If the gap between the top of the vertical plate and the rack is too small, the legs cannot be rotated in place, and the vertical plate is repaired; if the gap between the bottom of the vertical plate and the rack is too small If it is too small, the leg cannot be rotated in place. Adjust the bottom of the main chord to the outside to rotate the leg in place.

[0057] In this embodiment, when hoisting, the first section of the pile leg is staggered by 5° with the segmented vertical plate of the pile shoe, and then the first section of the pile leg is rotated. By checking the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com