Clothes folding rack assembly for ironer

A technology for ironing machines and clothes hangers, applied in folders, laundry room devices, folding thin materials, etc., can solve the problems of difficulty in ensuring the quality and low efficiency of folding clothes, and achieve the effect of high folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

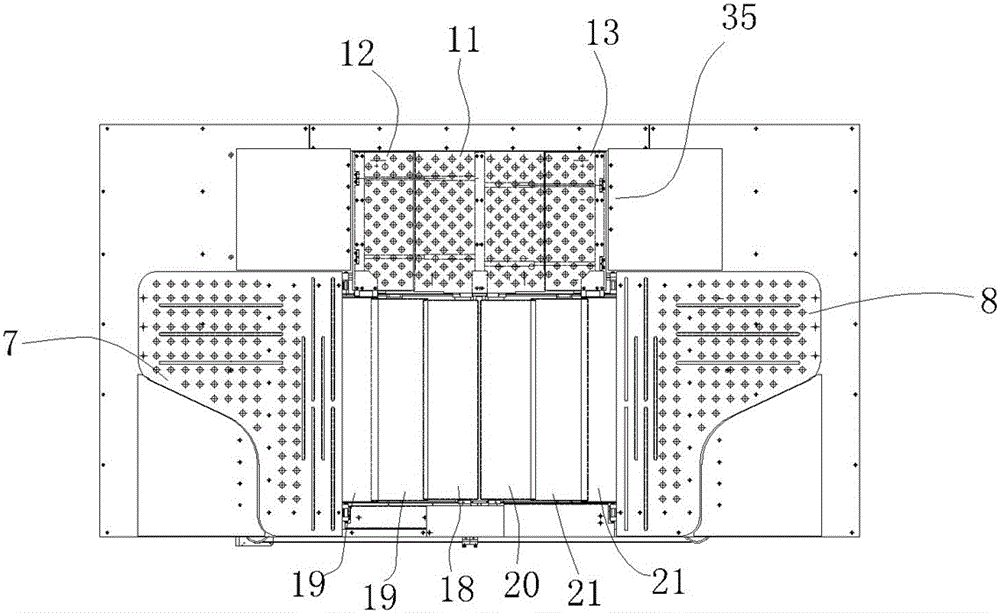

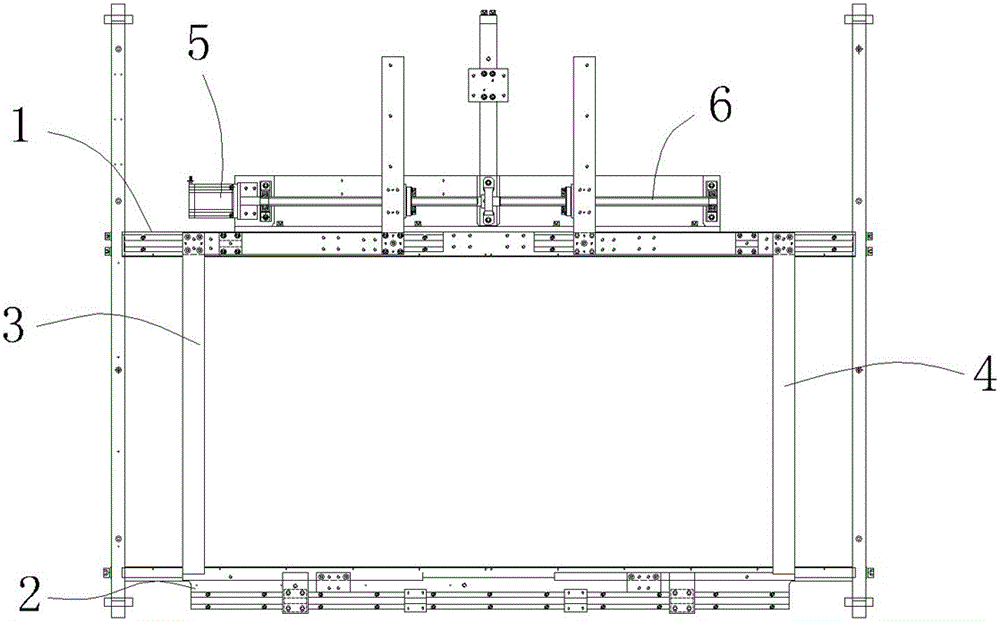

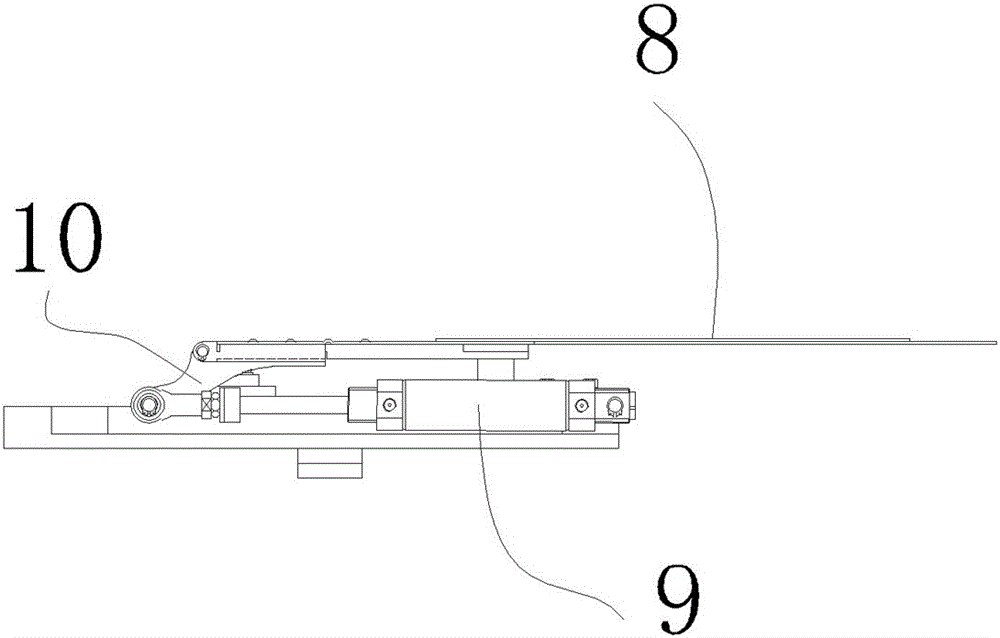

[0045] refer to Figure 1~Figure 14 , a folding hanger assembly of an ironing machine, including a bottom frame, the bottom frame has a front support beam 1 and a rear support beam 2, and a left sliding frame is slid on the front support beam 1 and the rear support beam 2 3. The right carriage 4 located on the right side of the left carriage 3, the left carriage 3 and the right carriage 4 are connected with a sliding drive mechanism for driving both slides, and the sliding drive mechanism drives the left The carriage 3 and the right carriage 4 move toward or away from each other. In this embodiment, the sliding driving mechanism includes a sliding driving motor 5 arranged on the chassis, the output shaft of the sliding driving motor 5 is connected to the screw rod 6, and the left sliding frame 3 and the right sliding frame are 4 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com