Method for producing N-acetylneuraminic acid by spore surface display system

A surface display system, acetylneuraminic acid technology, applied in the field of N-acetylneuraminic acid production, can solve the problems of whole-cell catalytic conversion rate of toxic substances, difficulty in large-scale production, and large-scale preparation of free enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

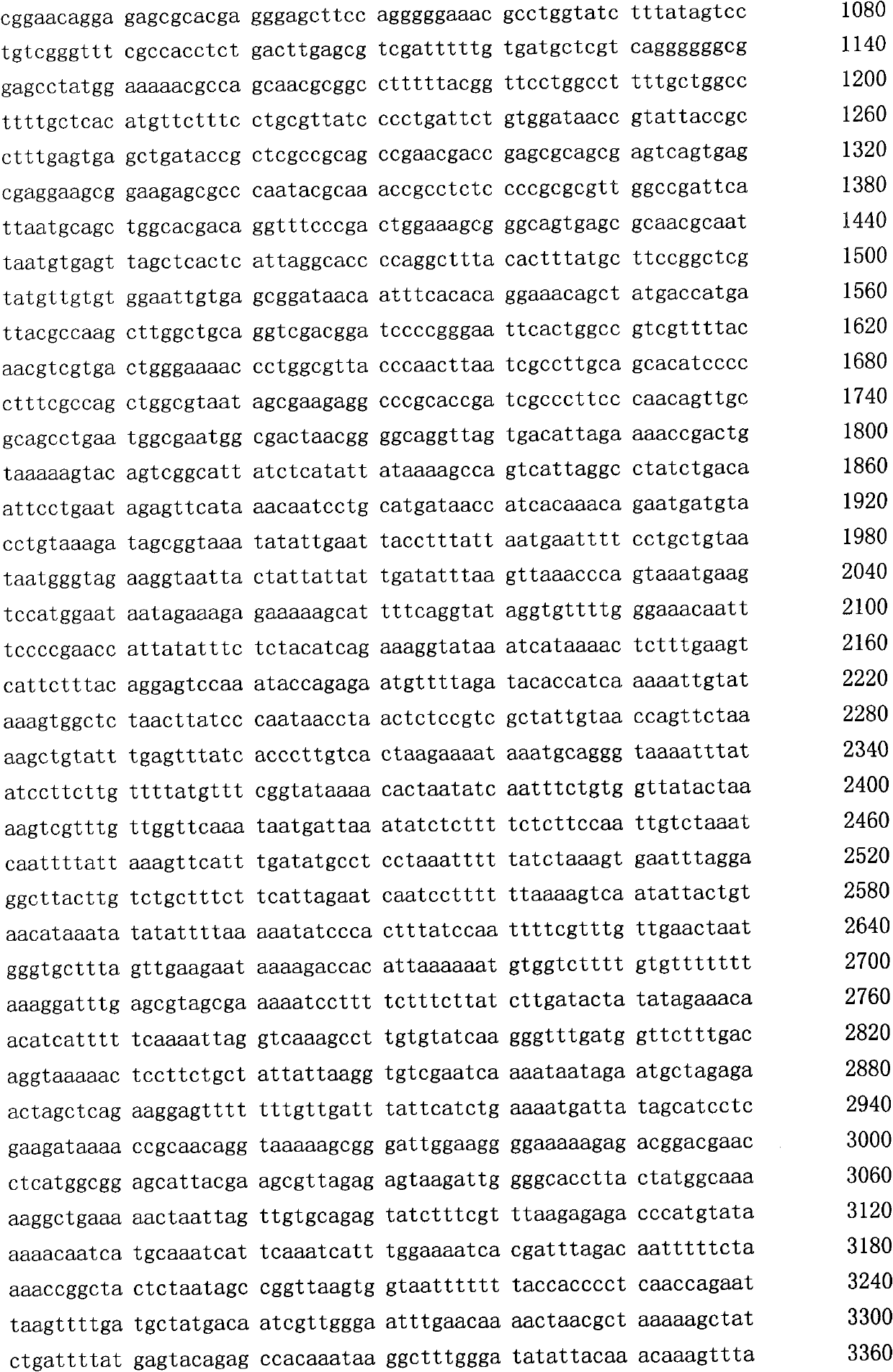

[0065] Embodiment 1: Construction of high copy shuttle vector pHPGD

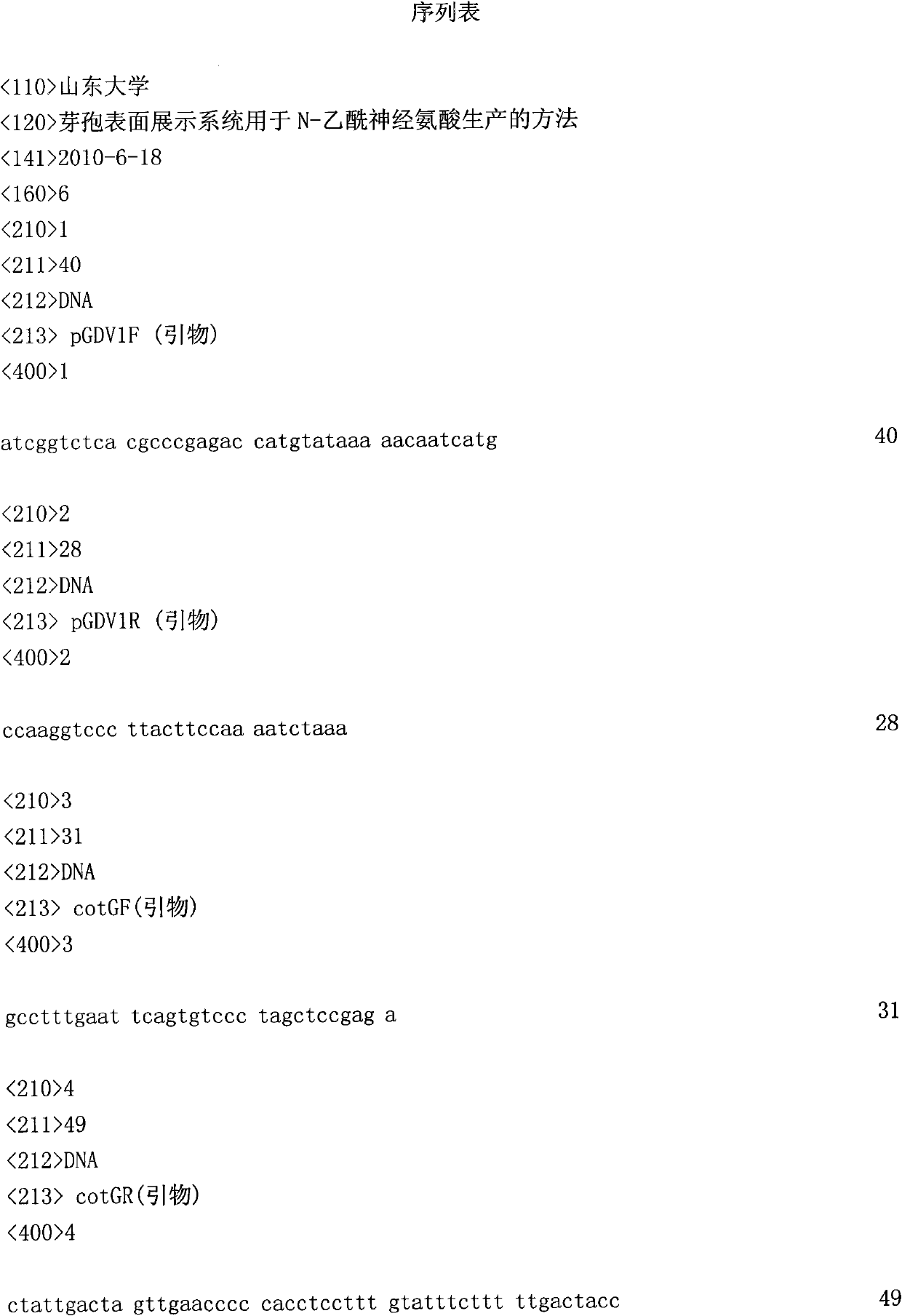

[0066] 1. Cloning of pGDV1 replicon

[0067] The plasmid pGDV1 of Bacillus subtilis 168 was extracted by a conventional method. For this process, reference may be made to the method for small-scale preparation of bacterial plasmids in the "Guidelines for Molecular Biology" published by Science Press. Using the synthesized primers, a high-copy replicon gene was amplified by PCR from the extracted plasmid pGDV1.

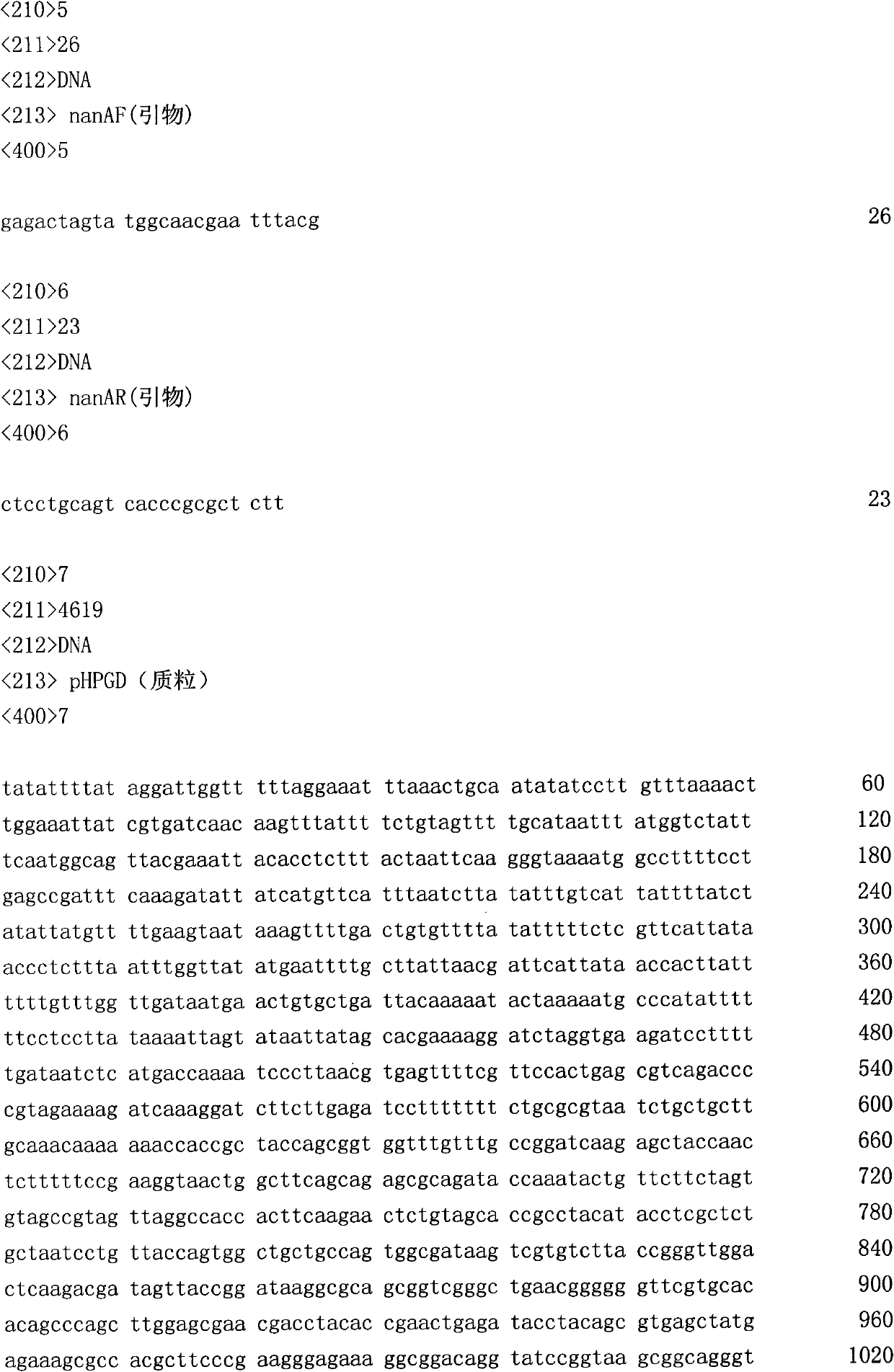

[0068] Among them, pGDV1 was purchased from Bacillus Genetic Stock Center (BGSC), Germany, and the query number was 1E60; the above-mentioned Bacillus subtilis was used as the source of the replicon gene, and primers were designed according to the known sequence of pGDV1: upstream primer pGDV1F: 5 '-ATCGGTCTCACGCCCGAGACCATGTATAAAAAACAATCATG-3', carrying a BasI restriction site; downstream primer pGDV1R: 5'-CCAAGGTCCCTTACTTCCAAAATCTAAA-3', carrying an EcoO109I restriction site.

[0069] 2. Construct...

Embodiment 2

[0074] Example 2: Construction of high-efficiency spore surface display system Bacillus subtilis (Bacillus subtilis) WB600 (PHPGD-cotG-nanA)

[0075] 1. Cloning of spore coat protein CotG gene (cotG)

[0076] Genomic DNA of Bacillus subtilis 168 was prepared by a conventional method. For this process, reference may be made to the method for small-scale preparation of bacterial genomes in "Guidelines for Molecular Biology" published by Science Press. The cotG gene was amplified by PCR from the genomic DNA of Bacillus subtilis 168 using synthetic primers cotGF and cotGR.

[0077] Wherein, the above-mentioned Bacillus subtilis 168 was purchased from Bacillus Genetic Stock Center (BGSC), Germany, and the query number is 1A1.

[0078] Primers were designed according to the reported genome sequence of Bacillus subtilis 168 and the reported cotG gene sequence.

[0079] Upstream primer cotGF:

[0080] 5'-GCCTTTGAATTCAGTGTCCCTAGCTCCGAGA-3', carrying an EcoRI restriction site;

[00...

Embodiment 3

[0107] Embodiment 3: The method that spore surface display system is used for the production of N-acetylneuraminic acid

[0108] (1) Plate culture: Streak the above-mentioned Bacillus subtilis (Bacillus subtilis) WB600 (PHPGD-cotG-nanA) strain onto a chloramphenicol LB plate containing 1.5% agar by mass volume ratio and containing 40 μg / ml, at 37° C. Incubate for 12 hours.

[0109] (2) first-class seed: under sterile conditions, pick a single colony on the flat plate of step (1) with a sterile toothpick, then inoculate into 5ml of liquid medium containing 40 μg / ml chloramphenicol, Incubate on a shaker at 37°C for 12 hours.

[0110] (3) Shake flask culture: under aseptic conditions, take the culture solution cultivated in step (2) with a volume ratio of 5% inoculum, and inoculate it into 1L of GYS medium containing 40 μg / ml of chloramphenicol, Incubate on a shaker at 37°C for 24 hours.

[0111] Wherein, the formula of the LB medium in the above (2) is: add 5 g of yeast powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com