Cloth overlock device for cloth processing and overlock method

A fabric and edge locking technology, which is applied in fabric edge trimming, fabric feeding mechanism, fabric kneading/softening treatment, etc., can solve the problems of fabric edge banding deviation, difficult folding of precise size, low efficiency, etc. To achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

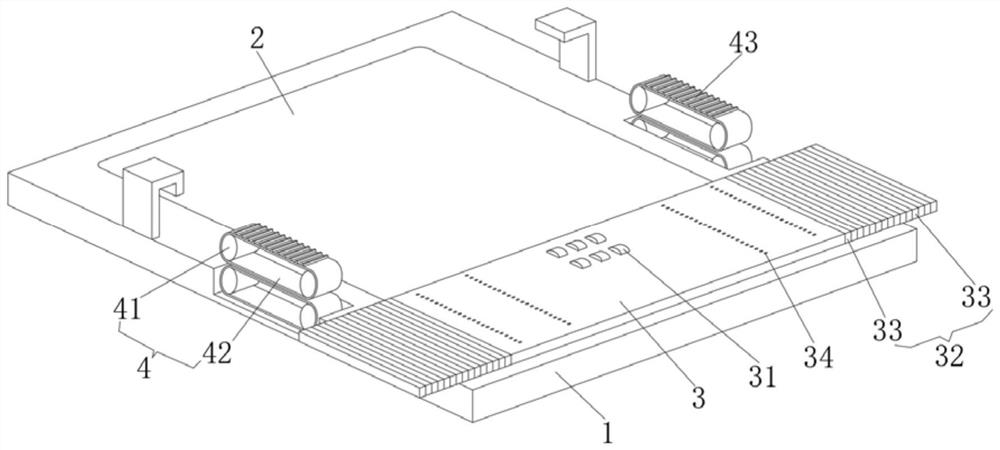

[0025] see Figure 1-2 , this embodiment provides a fabric sewing device for fabric processing, including a fabric conveying platform 1, the top surface of the fabric conveying platform 1 is provided with a sewing machine head, the sewing machine head is mainly used to sew and fix the folded area of the fabric.

[0026] The top surface of the cloth conveying platform 1 is provided with a conveying belt 2, and the surface of the conveying belt 2 can be provided with anti-skid lines, so that the cloth can be well conveyed during the edge sealing process.

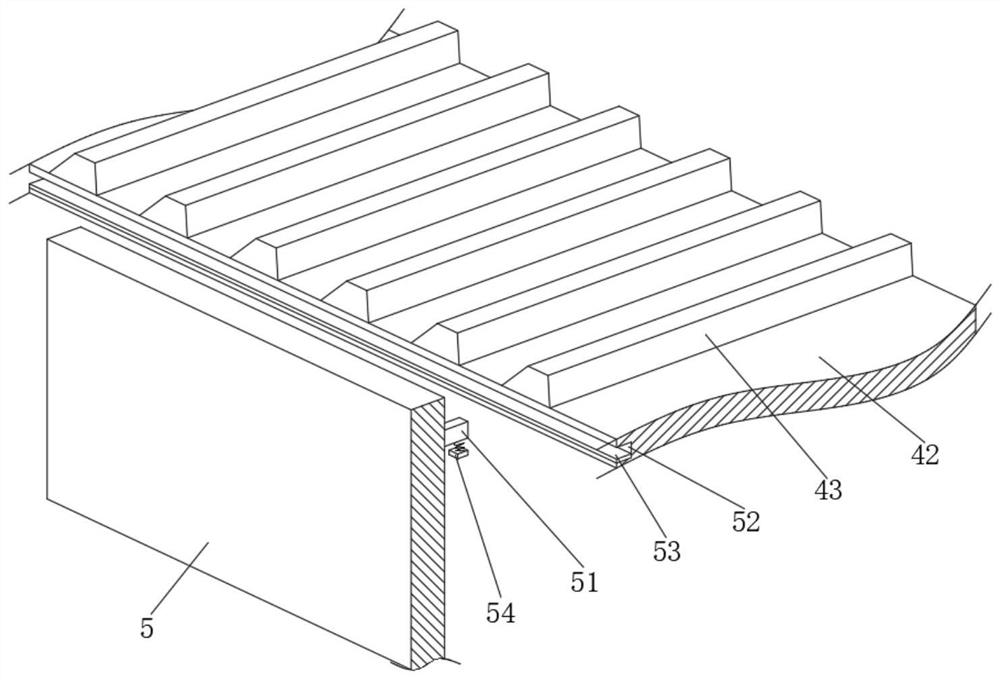

[0027] One side of the cloth transfer platform 1 is provided with a flanging plate 3 close to the conveyor belt 2, and the flanging plate 3 utilizes the bending of its side movable plate 32 to realize the folding of the corners of the cloth, and the flanging plate 3 and the conveyor belt 2 A conveyor belt 4 is arranged between them, and the conveyor belt 4 transmits the folded cloth, and uses two pressing belts 42 to press t...

Embodiment 2

[0038] see Figure 3-5 , On the basis of embodiment 1, a further improvement has been made: in the process of fabric production and processing, there are some fabrics of chemical materials, and the fabrics of chemical materials are often sealed by hot melting.

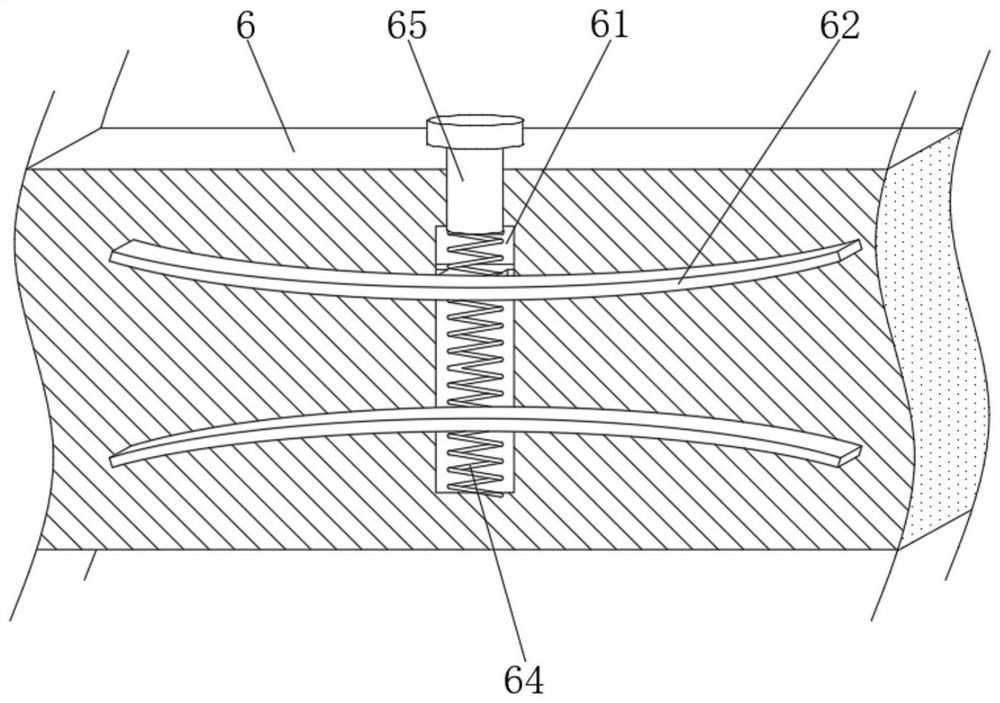

[0039] In order to satisfy the edge banding of fabrics made of special materials, an edge banding plate 6 is provided on the top surface of the cloth conveying platform 1 close to the conveyor belt 4, and a chute 61 is opened on the side of the edge banding plate 6 close to the conveyor belt 4, and the inside of the chute 61 There are two heating plates 62 with L-shaped structure slidingly installed. Heating wires are installed inside the heating plates 62. After the heating wires are energized, the temperature of the heating plates 62 rises. When the folded part of the fabric passes through the two heating plates When the temperature is between 62 and 62, under the effect of high temperature, a small amount of melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com