Color-deepening finishing agent for dyed polyester textiles

A technology of polyester fabric and finishing agent, applied in fiber processing, textile and papermaking, etc., can solve problems such as restricting product development and promotion, and achieve the effect of improving color fastness performance, enhancing color depth effect, and saving textile resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

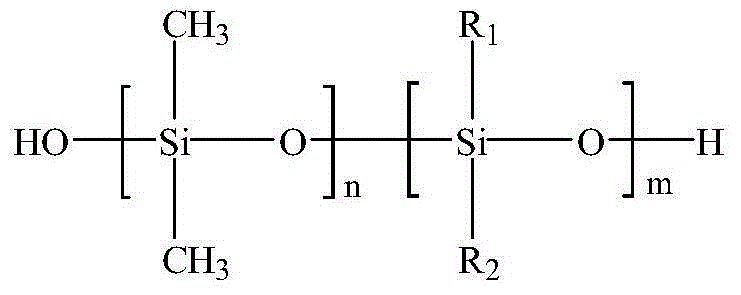

Method used

Image

Examples

Embodiment 1

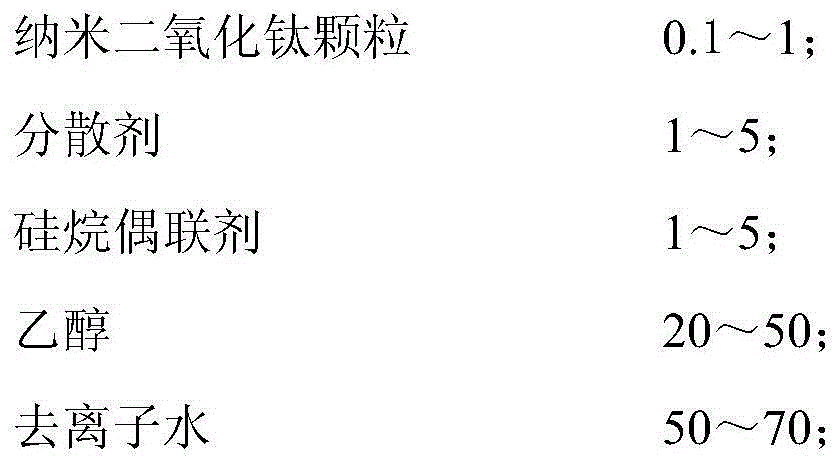

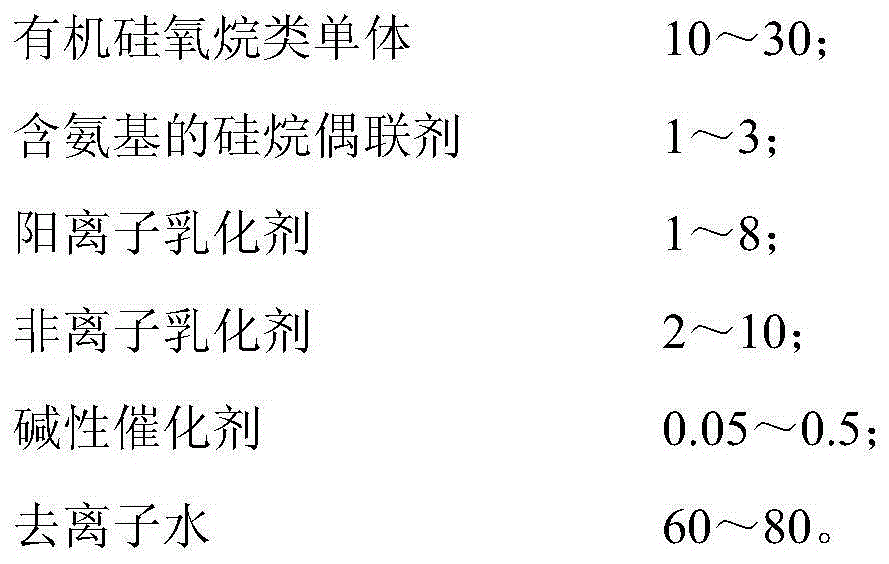

[0026] The preparation of the darkening finishing agent that dyed polyester fabric is used comprises the steps:

[0027] Add 1g of nano-titanium dioxide particles to 50mL of 5% triethanolamine aqueous solution, stir and mix for 2 hours, raise the temperature to 80°C, and add 50mL of γ-methacryloyl with a mass fraction of 0.5% (ethanol) dropwise. Oxypropyltrimethoxysilane was used for modification, and the stirring speed and reaction temperature were kept, and the reaction was carried out for 2 hours to prepare a modified nano-titanium dioxide emulsion. According to mass percentage, 2g of cetyltrimethylammonium bromide and 6g of fatty alcohol polyoxyethylene ether AEO-3 were dissolved in 50mL of deionized water, and 20g of octamethylcyclotetrasiloxane and 2g of N- (β-Aminoethyl)-γ-aminopropylmethyldimethoxysilane, and high-speed stirring, homogenization for 30 minutes to obtain a milky white pre-emulsion; dissolve 2g of cetyltrimethylammonium bromide Use 50mL of deionized wate...

Embodiment 2

[0033] The preparation of the darkening finishing agent that dyed polyester fabric is used comprises the steps:

[0034] According to the mass percentage, 0.1g of nano-titanium dioxide particles were added to 50mL of 0.5% octylphenol-10 aqueous solution, fully stirred and mixed for 1 hour, the temperature was raised to 75°C, and the mass fraction was added dropwise to 0.2% (the solvent was ethanol ) of γ-methacryloxypropyltrimethoxysilane for modification, keeping the stirring speed and reaction temperature, and reacting for 1 hour to prepare a modified nano-titanium dioxide emulsion. According to mass percentage, dissolve 2g of cetyltrimethylammonium bromide and 6g of fatty alcohol polyoxyethylene ether AEO-7 in 50mL of deionized water, add 20g of octamethylcyclotetrasiloxane and 2g of γ-ammonia dropwise Propyltriethoxysilane, and high-speed stirring, homogenization for 30 minutes, obtained a milky white pre-emulsion; 2g of cetyltrimethylammonium bromide was dissolved in 50mL...

Embodiment 3

[0041] The preparation of the darkening finishing agent that dyed polyester fabric is used comprises the steps:

[0042] According to the mass percentage, 2g of nano-titanium dioxide particles were added to 50mL of 5% Tween-80 aqueous solution, fully stirred and mixed for 1.5 hours, the temperature was raised to 60°C, and 50mL of 5% (solvent was ethanol) was added dropwise. γ-glycidyl etheroxypropyl trimethoxysilane was used for modification, and the stirring speed and reaction temperature were kept, and the reaction was carried out for 2 hours to prepare a modified nano-titanium dioxide emulsion. According to mass percentage, dissolve 2g octadecyltrimethylammonium chloride, 3g fatty alcohol polyoxyethylene ether AEO-3 and 3g octylphenol polyoxyethylene ether OP-10 in 50mL deionized water, and add 20g Hexamethyltrisiloxane and 1g N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane were stirred at high speed and homogenized for 40 minutes to obtain a milky white pre-emulsion; 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com