Automatic screw machine based on visual identification and screw installation method thereof

A visual recognition and screw machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to guarantee product processing accuracy and service life, high labor intensity, low production efficiency, etc., to save labor resources, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

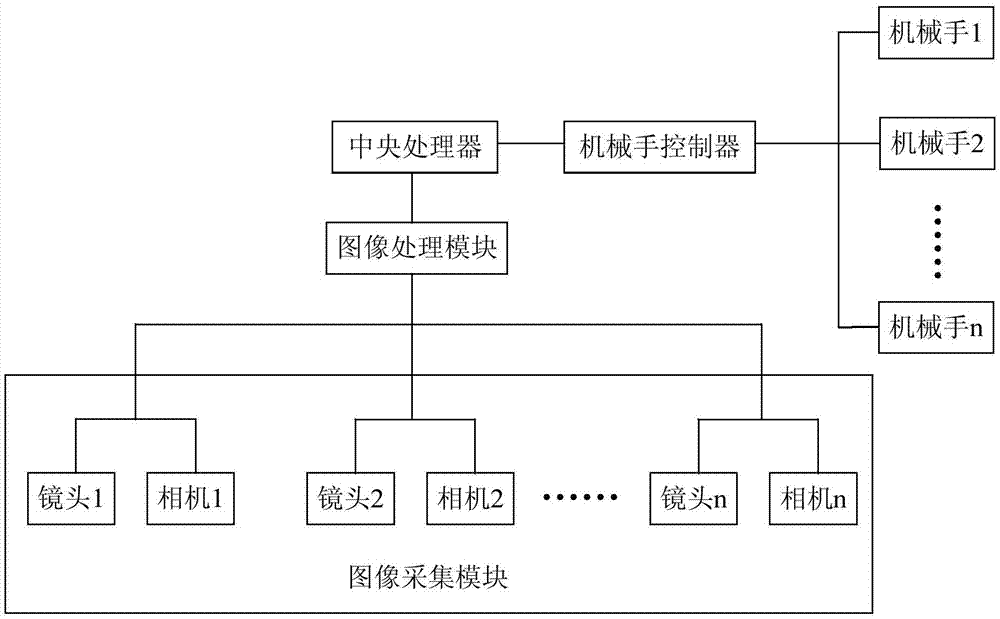

[0023] Such as figure 1 As shown, the automatic screw machine based on visual recognition of the present invention includes a visual recognition system, and the visual recognition system includes an image acquisition module and an image processing module, and the image acquisition module is used to collect image information of screw mounting holes. The image acquisition module includes at least one lens and at least one camera. The lens is used in conjunction with the camera, that is, a lens and a camera are used as a whole. The camera in this embodiment is a CCD camera. In this embodiment, there are multiple lenses and cameras. In this embodiment, the number of lenses and cameras can be set to n, where n≥3.

[0024] Both the lens and the camera are connected to the image processing module, and the image processing module obtains the image information of the screw mounting holes through the lens and the camera, and then converts the obtained image information into digital info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com