High-efficiency energy-saving type internal insulation day-light greenhouse

A solar greenhouse, energy-saving technology, applied in greenhouse cultivation, energy-saving measures, agricultural machinery and equipment, etc., can solve the problems of increasing safety hazards, wasting labor resources, wasting manpower, etc., to improve the ability to resist wind and snow, save labor resources, The effect of reducing operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

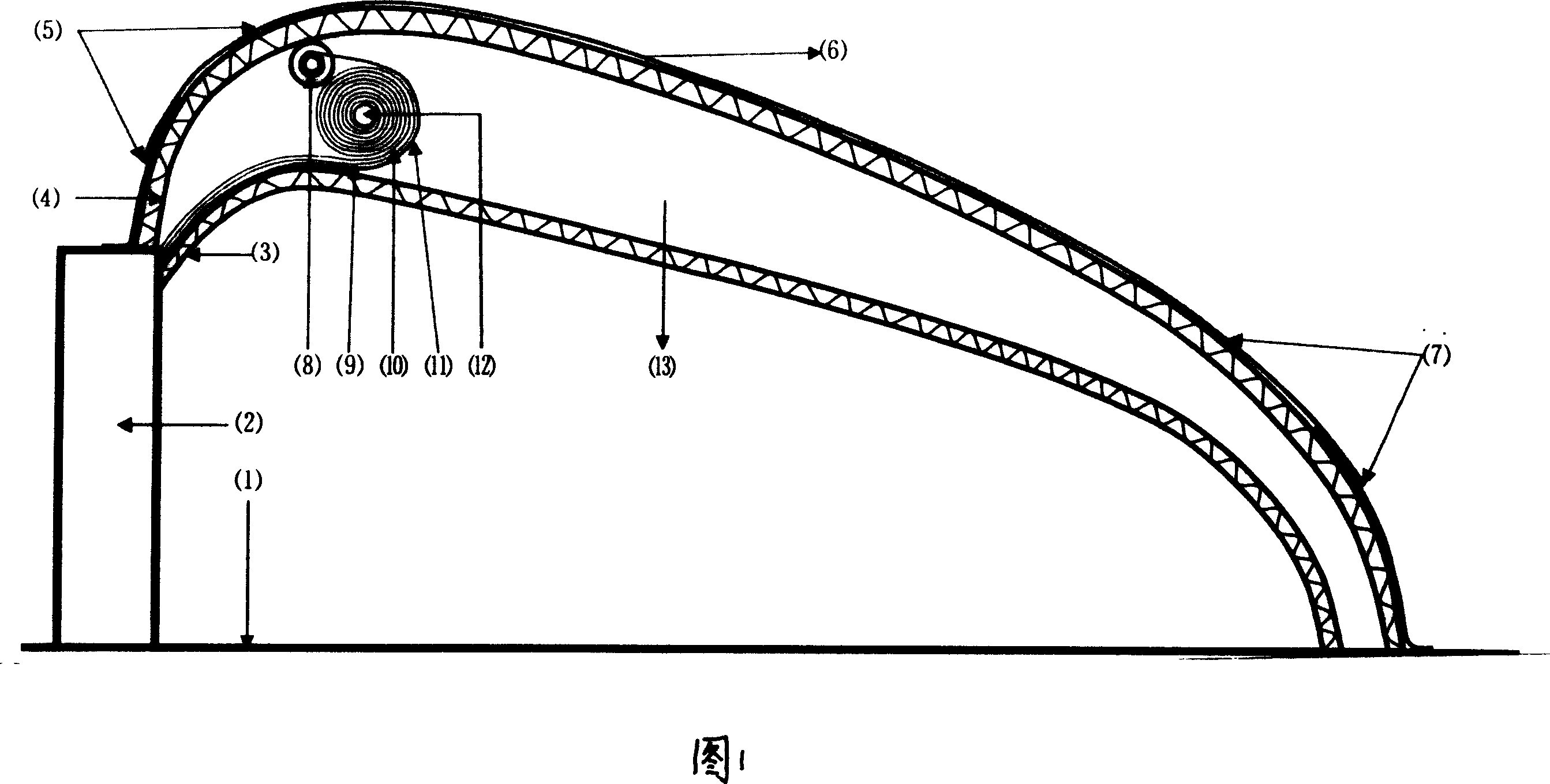

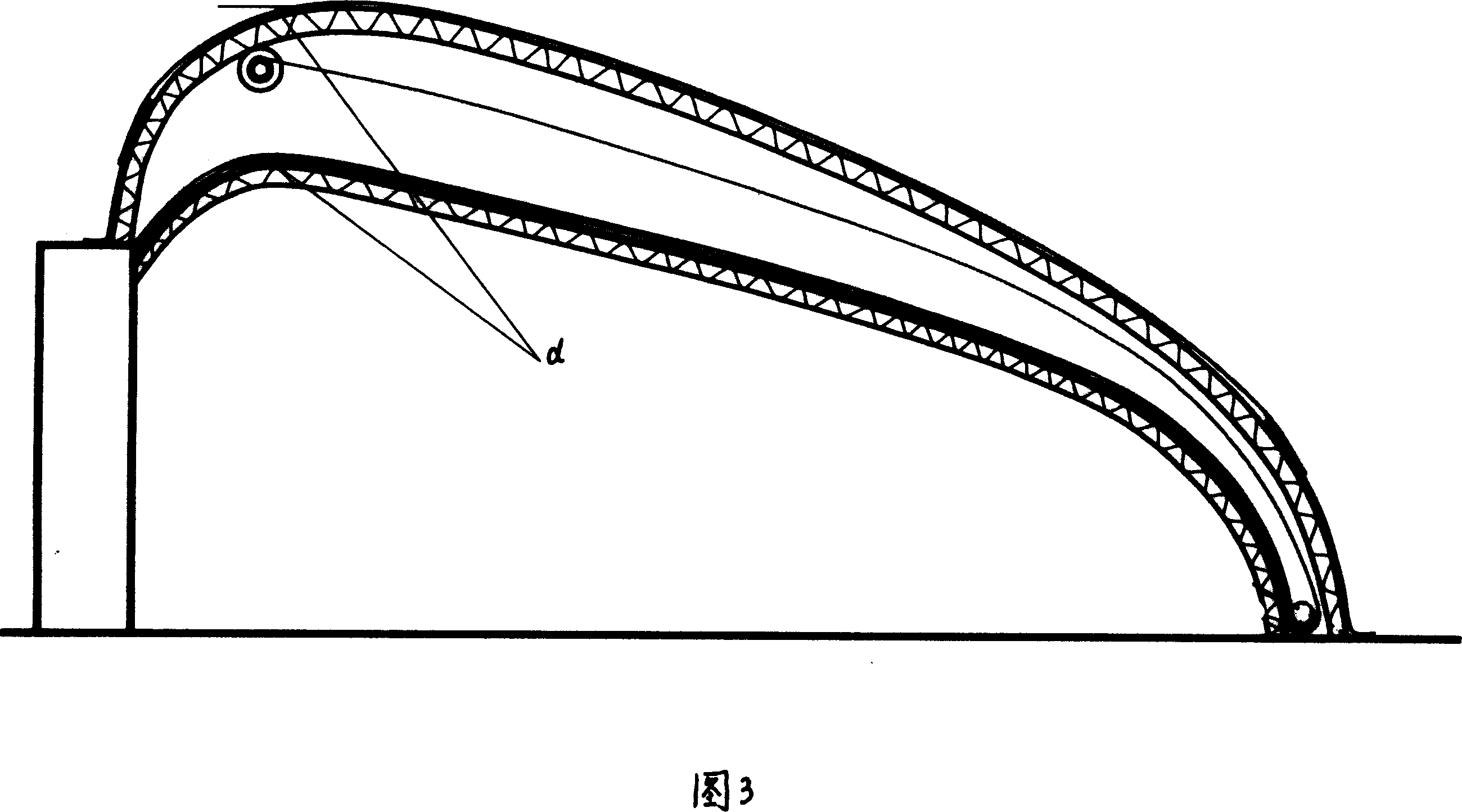

[0019] As shown in FIG. 1 , a high-efficiency and energy-saving thermal insulation solar greenhouse is fixedly installed on the ground plane 1 and the wall 2 . It consists of inner and outer frames 3 and 4, and the outer frame is provided with a rear air outlet 5 and a front air outlet 7. The surface of the inner and outer skeletons is respectively provided with an inner layer waterproof insulation film 9 and an outer layer of light-transmitting thermal insulation straw curtain (or thermal insulation quilt) 6, and a straw curtain (or thermal insulation quilt) 10 and a roller blind are arranged between the inner and outer layer skeletons. device, and an air heat insulation layer 13 is formed between the inner and outer skeletons.

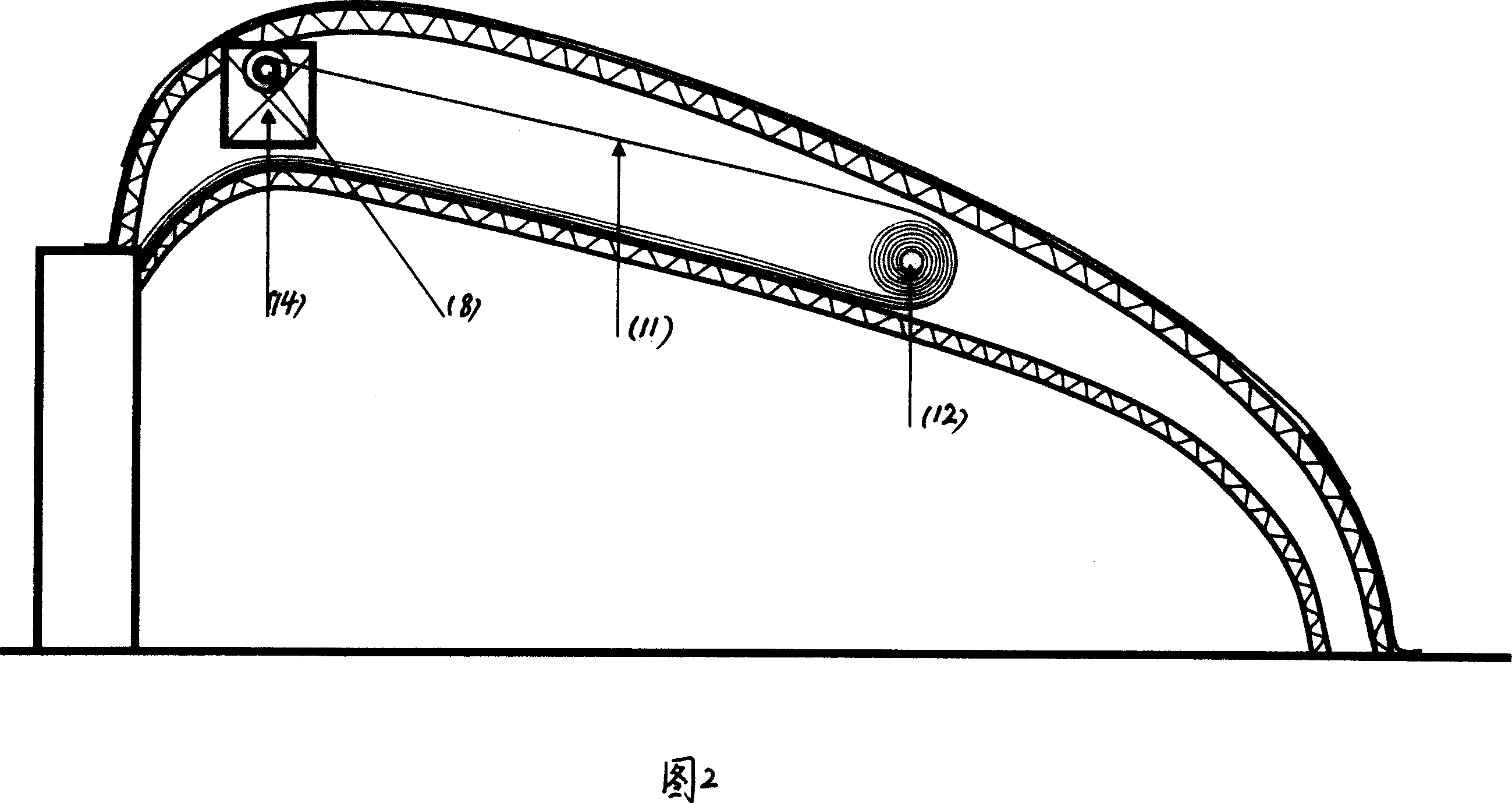

[0020] As shown in Figures 1 and 2: the above-mentioned shutter device is composed of a shutter machine 14, an active shutter shaft 8 fixed on the inside of the outer frame, a shutter rope 11 and a passive shutter shaft 12; the shutter machine and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com