Automatic production line for photo frames

A technology for automated production lines and photo frames, which is applied to picture frames, mirrors, household appliances, etc., can solve the problems of insufficient automation, production efficiency, low product quality, etc., to improve work efficiency and product quality, improve overall efficiency, and save labor. The effect of labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

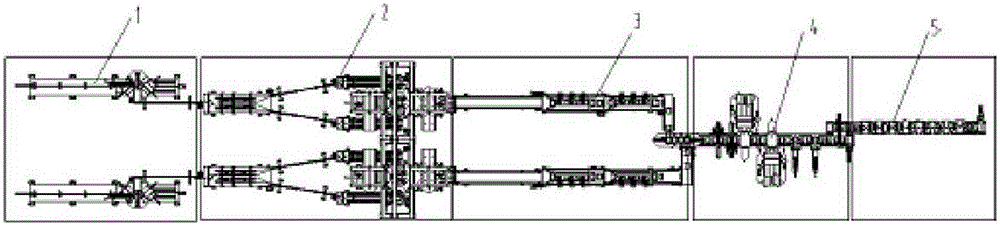

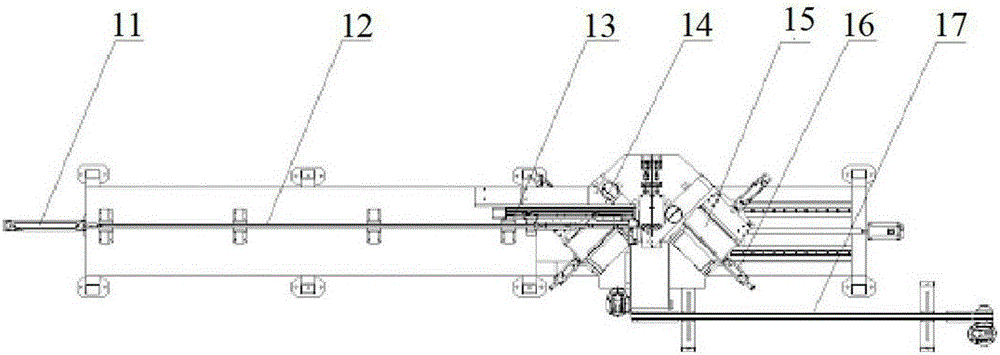

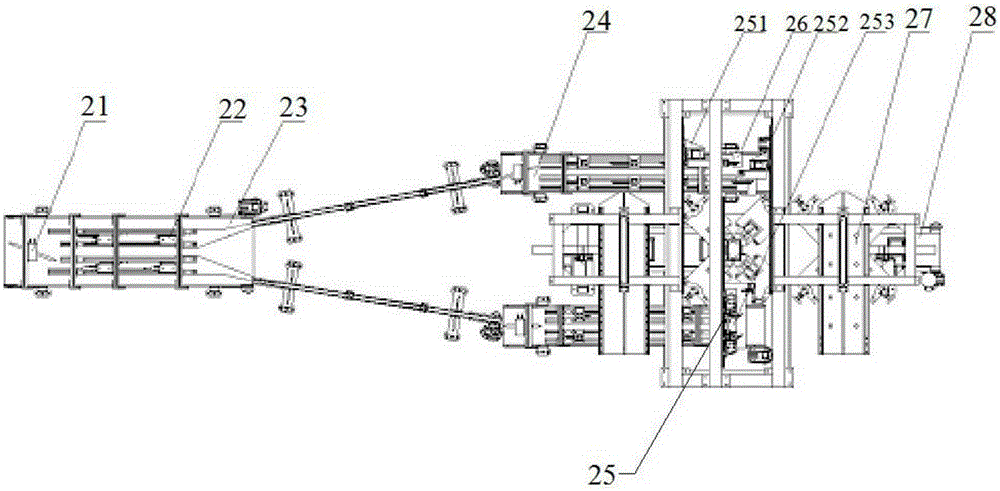

[0023] Photo frame automatic production line, including angle cutting machine 1, framing machine 2, cleaning machine 3, card issuing machine 4 and back nailing machine 5, the angle cutting machine 1, framing machine 2, cleaning machine 3, card issuing machine 4 and back nailing machine The machines 5 are connected in sequence to form a production line with the functions of corner cutting, framing, cleaning, card issuance and back nailing. The corner cutting machine 1, frame grouping machine 2 and cleaning machine 3 are all provided with two groups, symmetrically placed, and the materials are cleaned. Conveying, corner cutting, and conveying the processed materials to the framing machine 2, the framing machine 2 conveys, swings, sprays glue and nails the materials, and conveys the processed materials to the cleaning Machine 3, the cleaning machine 3 cleans the front and back sides of the material, and transports the processed material to the card issuing machine 4, and the card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com