Method and auxiliary device for pasting strain gages on circular bar and strain gage placing template

A technology of auxiliary devices and strain gauges, applied in the direction of measuring devices, instruments, etc., can solve problems such as easy mutual influence and difficult operation, and achieve the effect of uniform spacing, improved flatness, and guaranteed parallelism of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

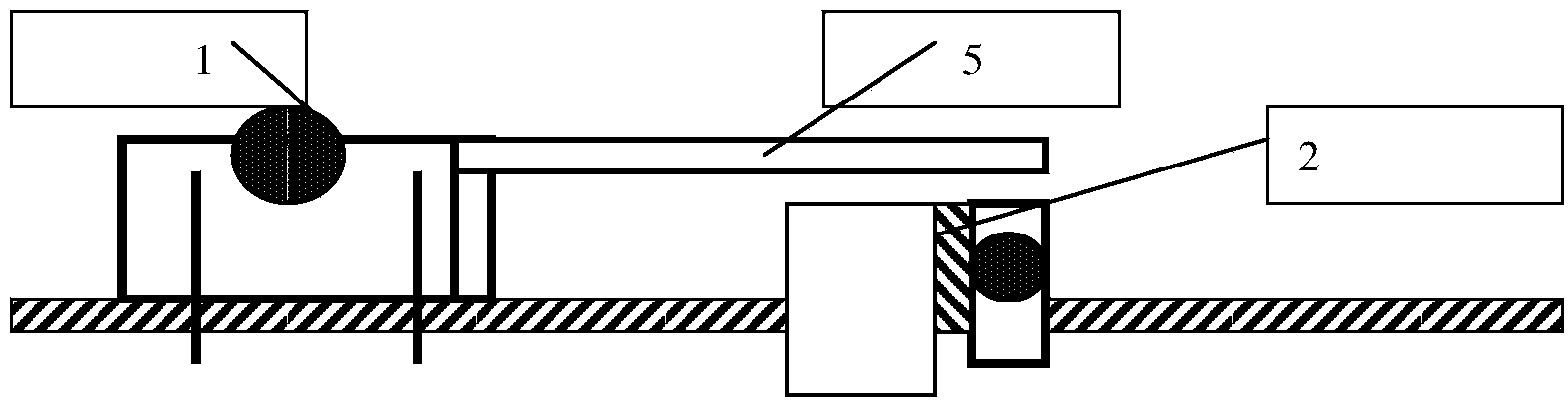

[0021] The strain gauge pasting auxiliary device is composed of a clamping rotator 1 and a sample clamping block 2. The sample clamping block 2 can be adjusted up and down, and a semi-cylindrical sample groove is arranged on its top surface. The diameter of the sample groove is adjusted according to the diameter of the round bar.

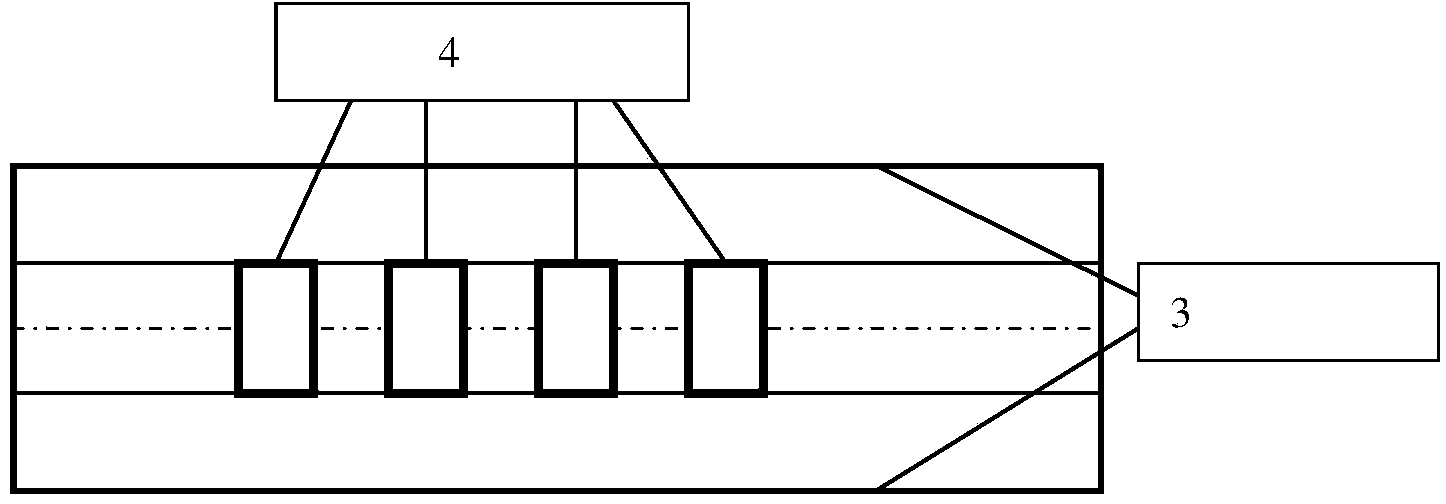

[0022] The template for placing the strain gauges is a rectangular flat plate on which tape scale lines 3 and strain gauge positioning wireframes 4 are engraved. The spacing of each wire frame is in accordance with the spacing requirements of the strain gauges of the corresponding bar specimens. The sides of the wireframe are parallel to the tape parallel lines. Wireframes are parallel to each other. The wireframe is centered between the parallel lines of the tape. The size of the strain gauge positioning wire frame 4 is adjusted accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com