Solvent-free UV (ultraviolet) curing glue for optical transparent adhesive tape and preparation method and application thereof

An optically transparent and curing glue technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of difficult control of product batch stability, high content of volatile organic compounds, and inability to produce thick OCA, etc. Achieve the effect of maintaining batch stability, high colloidal strength and high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

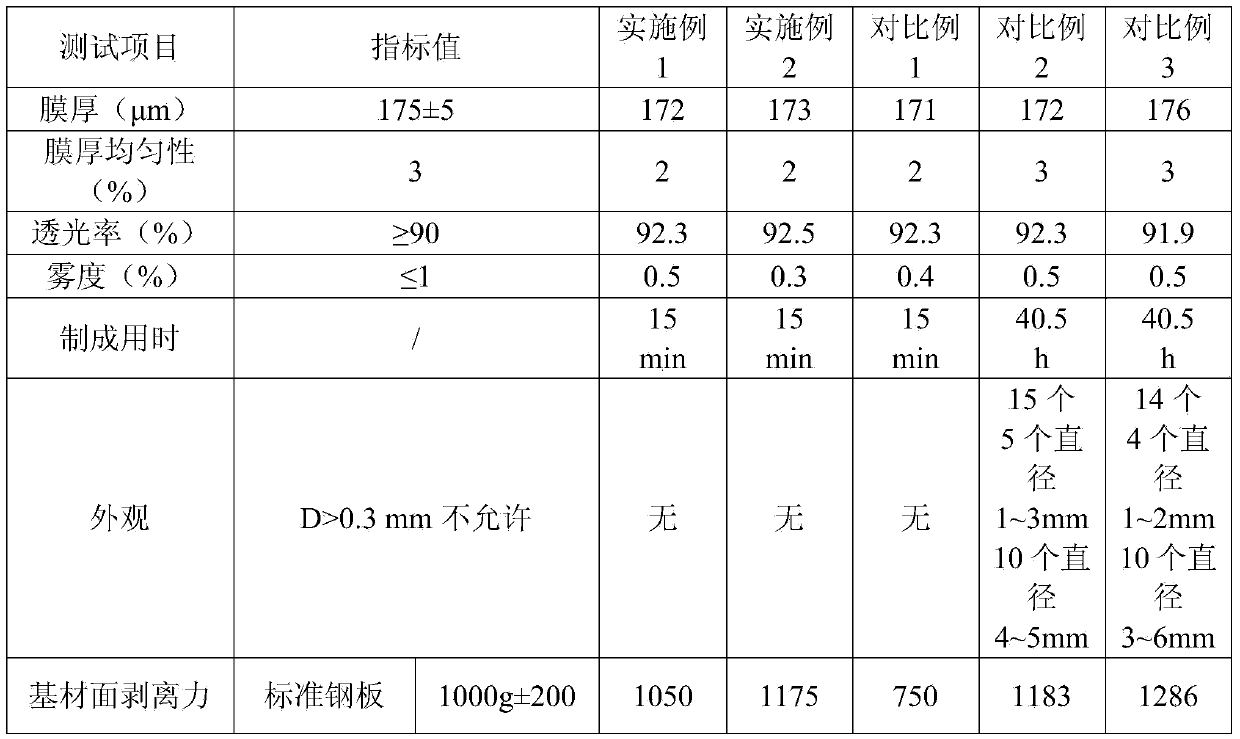

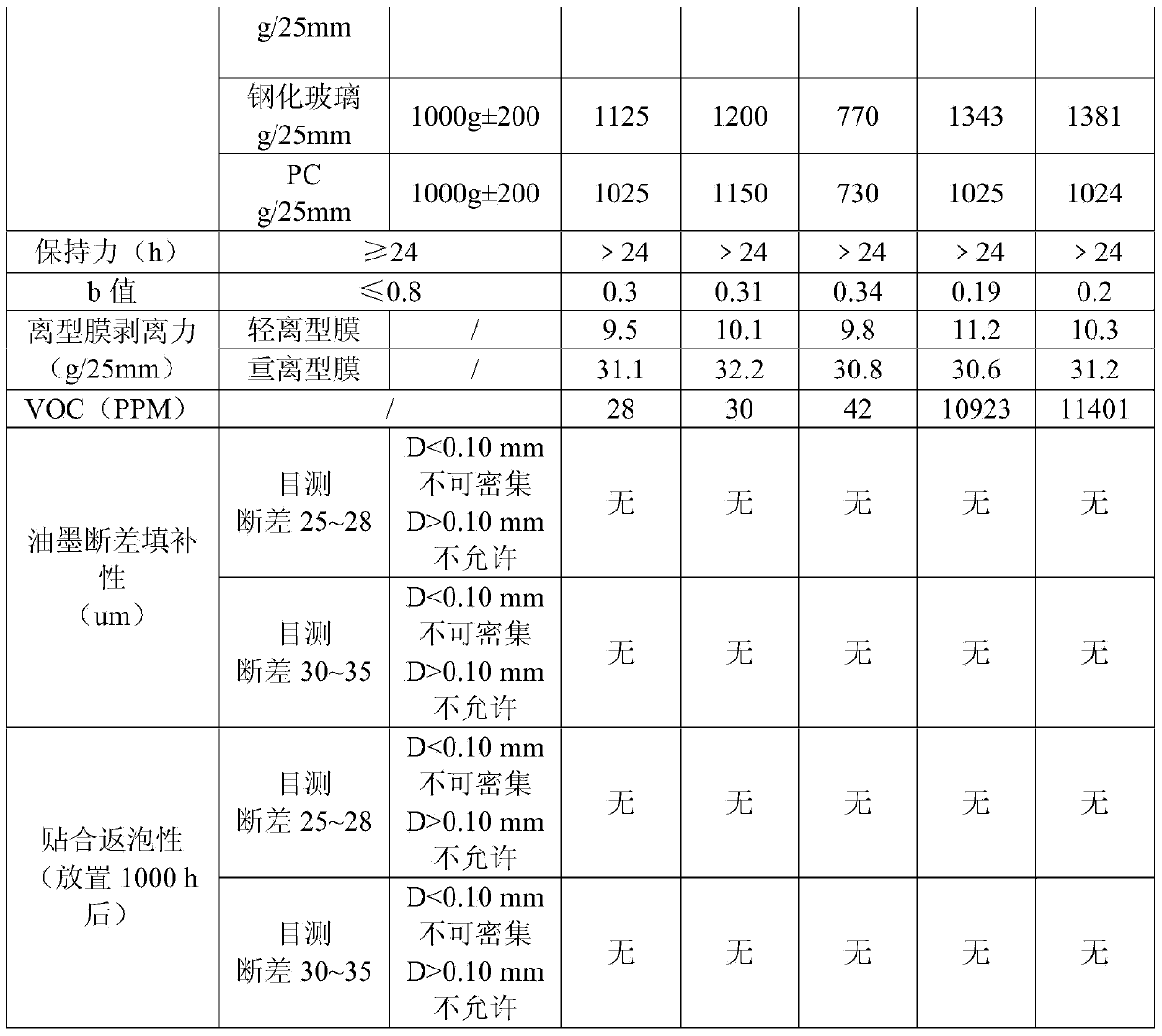

Examples

Embodiment 1

[0038] Embodiment 1: Preparation of solvent-free UV curing glue for optical scotch tape

[0039] Mix 60g mass parts of aliphatic urethane acrylate (Sartomer-CN965NS), 5g hyperbranched polyester acrylate (Sartomer-CN2303), then add 1g tackifying resin (E-5600BR), 20g acrylate monomer (Sartomer-SR395NS ), 5g of acrylate monomer (Eternal Chemical EM2411), mix well; then add 1g of ether-containing structure mercaptan (Nippon Synthetic Lecad803), mix well; add 0.5g of leveling agent (BYK-UV3570), 0.5g of defoaming agent Agent (BYK-057) and 1g photoinitiator (Irgacure127), mixed evenly, to obtain solvent-free UV curing glue for optical scotch tape.

Embodiment 2

[0040] Embodiment 2: Preparation of solvent-free UV curing glue for optical scotch tape

[0041] Mix 20g mass parts of aliphatic urethane acrylate (Sartomer-966J75NS), 5g hyperbranched polyester acrylate (Changxing Chemical 6361-100), then add 1g tackifying resin (E-5600BR), 5g acrylate monomer (Sartomer -454NS), 5g acrylate monomer (Eternal Chemical EM241), mix well; then add 1g ether-containing structure mercaptan (Nippon Synthetic Lecad804), mix well; add 0.5g leveling agent (BYK-UV3530), 0.5g Defoamer (BYK-088) and 2g photoinitiator (Irgacure2022), mixed evenly, to obtain solvent-free UV curing glue for optical scotch tape.

Embodiment 3

[0042] Embodiment 3: Preparation of solvent-free UV curing glue for optical scotch tape

[0043]Mix 50g mass parts of aliphatic polyurethane acrylate (Changxing 641), 5g hyperbranched polyester acrylate (Sartomer-CN2302), then add 1g tackifying resin (DS99), 10g acrylate monomer (Sartomer-506NS), 5g Acrylate monomer (Eternal Chemical EM265), mix evenly; then add 1g of ether-containing structure mercaptan (Japan Xibixi TMPT), mix evenly; add 0.5g leveling agent (BYK-UV3500), 0.5g defoamer (BYK-067A) and 2g photoinitiator (Irgacure184), mix well to get solvent-free UV curing glue for optical scotch tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com