Construction method of prestress carbon fiber cloth reinforced reinforced-concrete square pillar

A reinforced concrete and carbon fiber cloth technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of insufficient thickness of steel protective layer, damage of reinforced RC square columns, time-consuming and laborious noise and dust, etc., so as to improve the reinforcement effect and avoid The effect of the exposed anchorage and the reduction of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

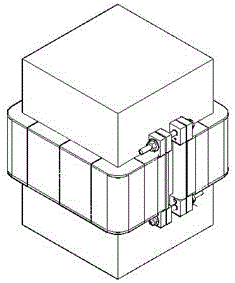

[0046] Such as Figure 1~12 As shown, this embodiment takes a 300mm side length RC square column as the reinforcement object, and uses prestressed CFRP to reinforce the RC square column. The construction method includes the following steps:

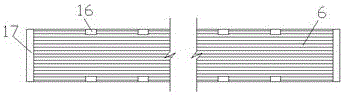

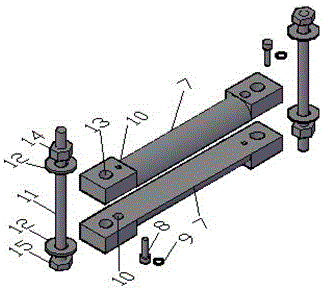

[0047] Step 1. Prefabricated modularized reactive powder concrete (RPC) cushions. The RPC cushions include corner arc blocks 4, ordinary rectangular blocks 5 and anchor side rectangular blocks 3. The radius of the corner arc block 4 is 30mm, the corresponding central angle is 90 degrees, and the length of the cushion block tangent to the arc corner is 50mm; the length of the ordinary rectangular block 5 and the anchor side rectangular block 3 along the column section direction is 100mm. The corner of the anchor side rectangular block on the side of the anchor is an arc corner with a radius of 10mm. The thickness of all pads is 30mm consistent with the thickness of the anchor. The height of the pad is the width of the pre-stressed CFRP clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com