Powder sampling method for X-fluorescence analysis

A fluorescence analysis and powder technology, applied in the field of chemical analysis, can solve problems such as easy cracking, corrosion of X-ray fluorescence spectroscopic crystals, damage to analysis equipment, etc., and achieve the effects of good quality and use effect, simple sample preparation method, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Smelting slag sample

[0020] Smelting slag is an important product of the pyrometallurgical smelting process in copper smelters. The chemical composition of the smelting slag can be used to judge the quality of the furnace indirectly. At the same time, the smelting slag is also the direct raw material for the mineral processing system of the copper smelter (slag beneficiation raw ore). The smelting slag contains about 2% copper, about 40% iron, and about 30% silicon dioxide, and its viscosity is relatively poor. It is difficult to obtain ideal samples by direct powder pressing method, and the surface of the samples is easy to fall off powder. Sometimes it cracks.

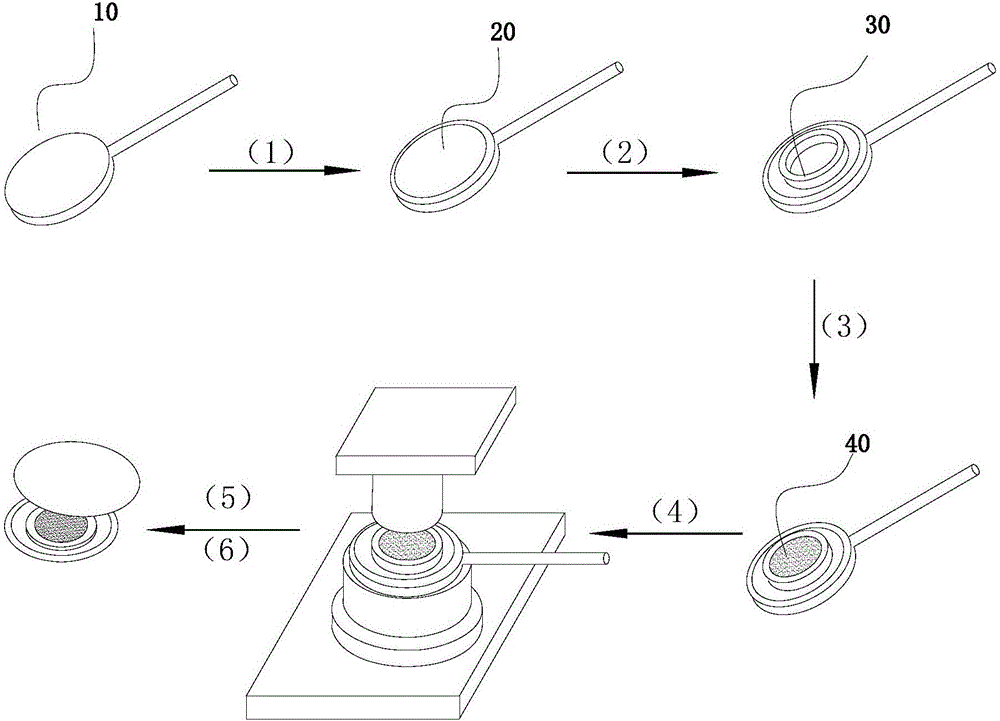

[0021] Tablet the smelt slag sample as follows:

[0022] (1) On the pressure-bearing tray 10, lay a layer of XRF discs with a thickness of 3.6 μm and a diameter of 63.5 mm to test the Mylar film 20;

[0023] (2) On the XRF disc test Mylar film 20, put a pressure sample with an outer diameter ...

Embodiment 2

[0043] Embodiment 2: slag separation tailings sample

[0044] The smelting slag leaves tailings after beneficiation, the copper grade is low, and the powder viscosity is poor. The direct sample pressing method cannot obtain qualified samples. The surface of the samples is easy to crack, and the powder will fall off during analysis. In a scattered state.

[0045] The powder sample is changed to a slag beneficiation tailings sample, and the tableting method is the same as that in Example 1 to obtain a slag beneficiation tailings sample.

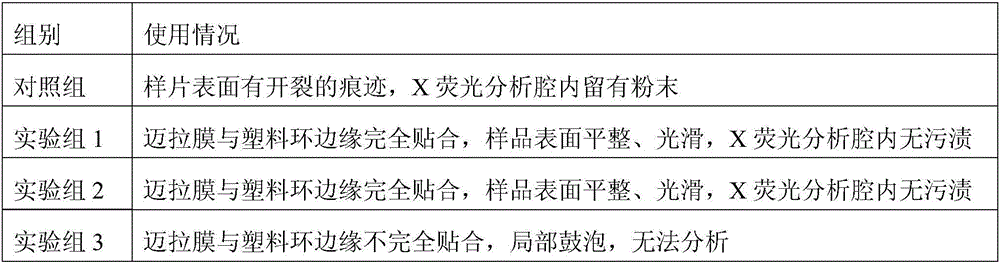

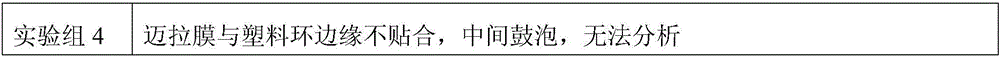

[0046] Performance test experiment:

[0047] Test 1: Control group: The slag beneficiation tailings samples were pressed into tablets using the conventional powder pressing method, specifically: the slag beneficiation tailings samples were directly pressed with an aluminum cover as the base, the obtained samples were subjected to X-ray fluorescence analysis, and the samples were taken out , to check the usage, see Table 4 for the results, and...

Embodiment 3

[0060] Example 3: Soot sample

[0061] A large amount of soot is produced during the copper smelting process. The composition of the soot returned to the furnace needs to be quickly analyzed by X-ray fluorescence. Since the soot sample contains a lot of acid, it is difficult to bake out all the acidic substances. If the soot is directly pressed into a tablet for X-ray fluorescence analysis, the soot sample will volatilize acidic substances under the irradiation of X-ray fluorescence, which will not only greatly corrode the X-ray fluorescence spectroscopic crystal, but also increase the vacuum degree of the vacuum chamber and increase the difficulty of analysis. .

[0062] The powder sample is changed to a soot sample, and the tableting method is the same as in Example 1 to obtain a soot sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com