Pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method

A technology of reinforced concrete columns and carbon fiber cloth, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems affecting the improvement of the bearing capacity of reinforced components, the reduction of the mechanical performance of carbon fiber cloth, and the fracture of carbon fiber cloth tows, etc., to achieve Improve the bearing capacity, increase the effective prestress, and reduce the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

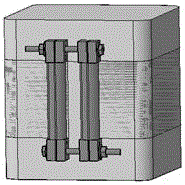

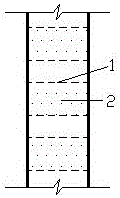

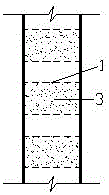

[0032] Such as Figure 1~7 As shown, the reinforcement in this embodiment is a square-section column, and the specific steps are:

[0033] Step 1. Grind and chamfer the four corners of the column to be reinforced with a grinder. The radius of the chamfered arc is greater than 25mm and ensure that it is a smooth arc. Determine the reinforcement position on the reinforced concrete column to be reinforced. Use ink line 1 It needs to be wrapped with pre-stressed carbon fiber cloth on its surface, then remove the surface scum, oil and other impurities, and polish it until the concrete structure surface is completely exposed. If the surface encounters large holes, it needs to use strong adhesion. The repair materials are used to fill holes.

[0034] Step 2. Apply a layer of epoxy glue evenly on the surface where the reinforced concrete column to be reinforced needs to be covered with prestressed carbon fiber cloth. The preparation process of epoxy glue is as follows: Stir the epoxy glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com