Positioning splicing method and device for sheets with patterns

A technology of positioning splicing and pattern pieces, which is applied in the directions of winding strips, transportation and packaging, and sending objects. It can solve the problems that the product pattern cannot be fixed, the relative position cannot be determined, and the pattern alignment cannot be satisfied, so as to achieve the ideal splicing effect. The effect of optimizing production process and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

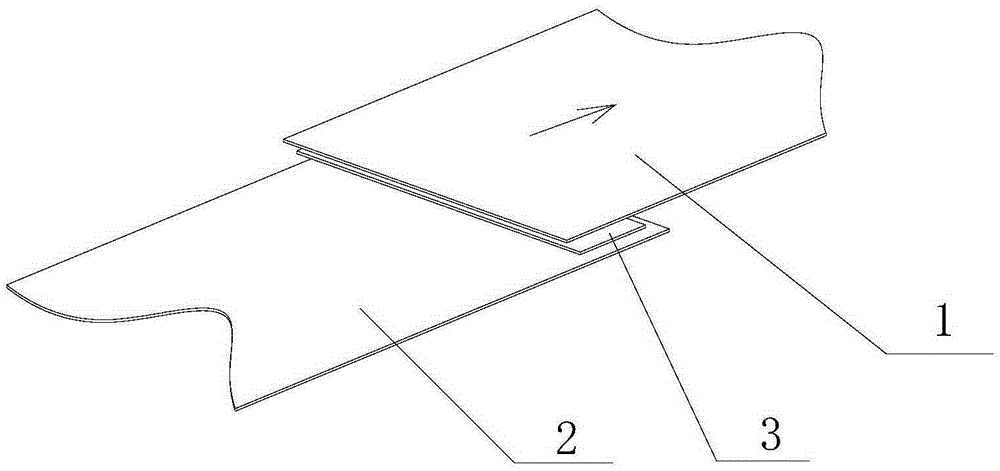

[0044] In this embodiment, a method for positioning and splicing patterned sheets comprises the following steps:

[0045] (1) Position the spare material and the used material first, so that the pattern on the spare material is aligned with the pattern on the used material;

[0046] Among them, the method for positioning the spare material is: set the positioning alignment marking line on the waste material extraction mechanism of the spare material and the conveying mechanism of the used material respectively, and use the pattern of the spare material at the positioning alignment marking line as the mark point, When the same pattern as the marked point on the used material is sent to the positioning alignment line of the used material, the pattern on the spare material is aligned with the pattern on the used material;

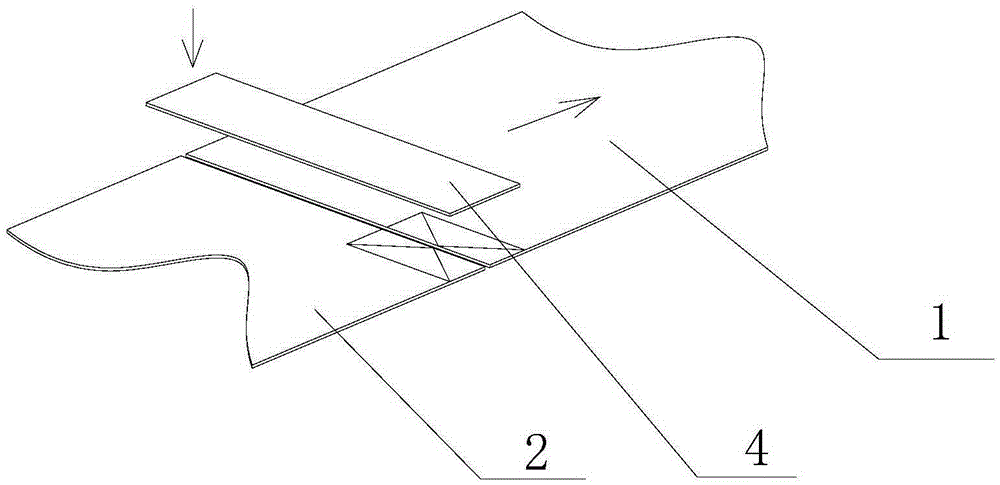

[0047] (2) Separately cut off the spare material and the used material to form aligned incisions;

[0048] Among them, before the spare material and the used...

Embodiment 2

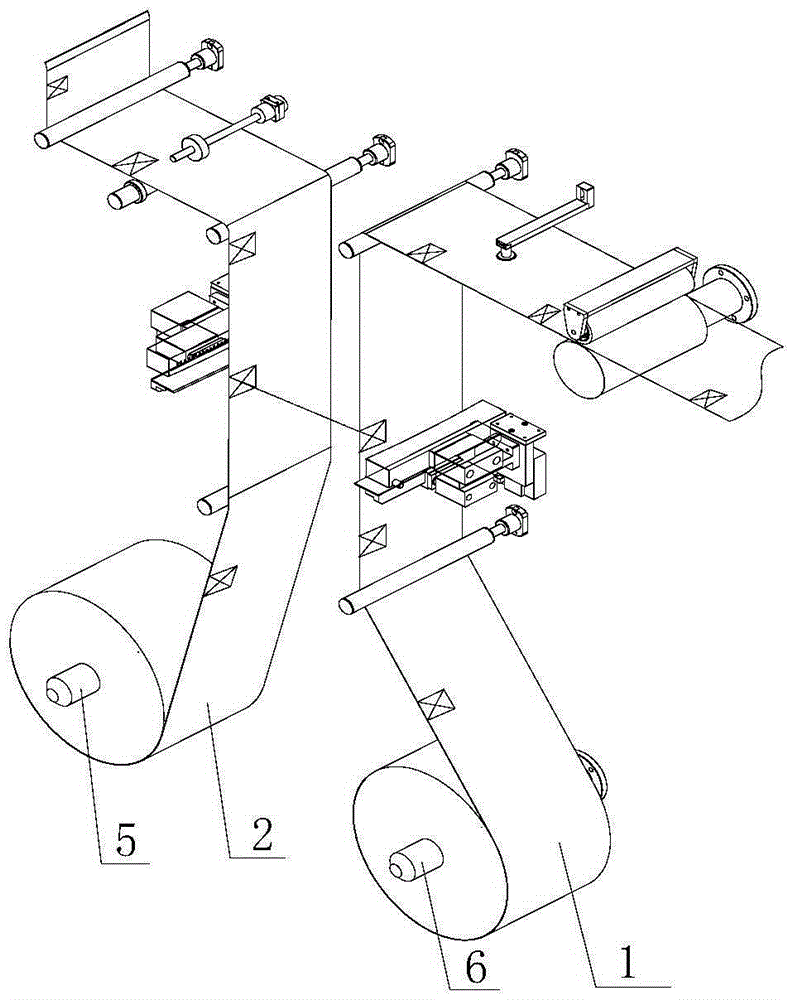

[0053] In this embodiment, a device for positioning and splicing patterned sheets that can realize the method described in Embodiment 1 includes an unwinding mechanism, a lower clamping mechanism, an upper clamping mechanism, a shearing and fixing mechanism, a waste material extraction mechanism, and a left pattern The positioning target and the right pattern positioning target, the upper clamping mechanism, the shearing fixing mechanism and the lower clamping mechanism are arranged in sequence between the unwinding mechanism and the waste material extraction mechanism, and the left pattern positioning target is set on the left side of the waste material extraction mechanism , the right pattern positioning target plate is set on the right side of the waste material extraction mechanism.

[0054] Such as Figure 3-9 As shown, the unwinding mechanism includes a left unwinding shaft and a right unwinding shaft, and the left unwinding shaft and the right unwinding shaft alternatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com