Method for measuring adhesive force of lithium ion battery pole piece coating

A lithium ion battery and a measuring method technology are applied in the field of lithium ion battery pole piece coating adhesion measurement, which can solve the problems such as the inability to quantitatively express the pole piece coating adhesion, affecting the quality improvement of lithium ion battery manufacturing, and the like, and achieving error Small, easy to measure, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] The lithium-ion battery pole piece coating adhesion measuring method of the present embodiment adopts the following steps:

[0014] 1. Test preparation of the pole piece to be tested:

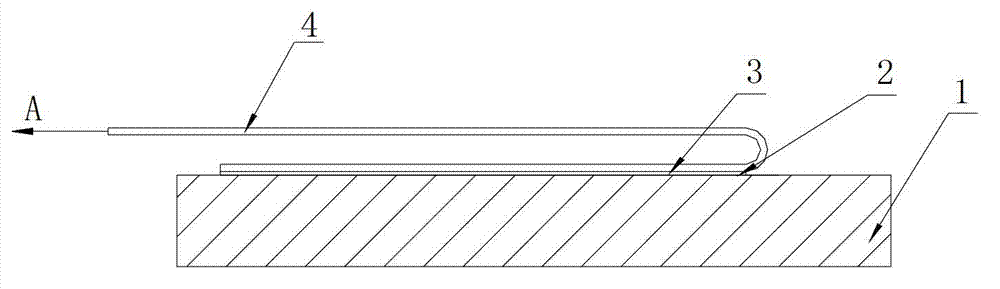

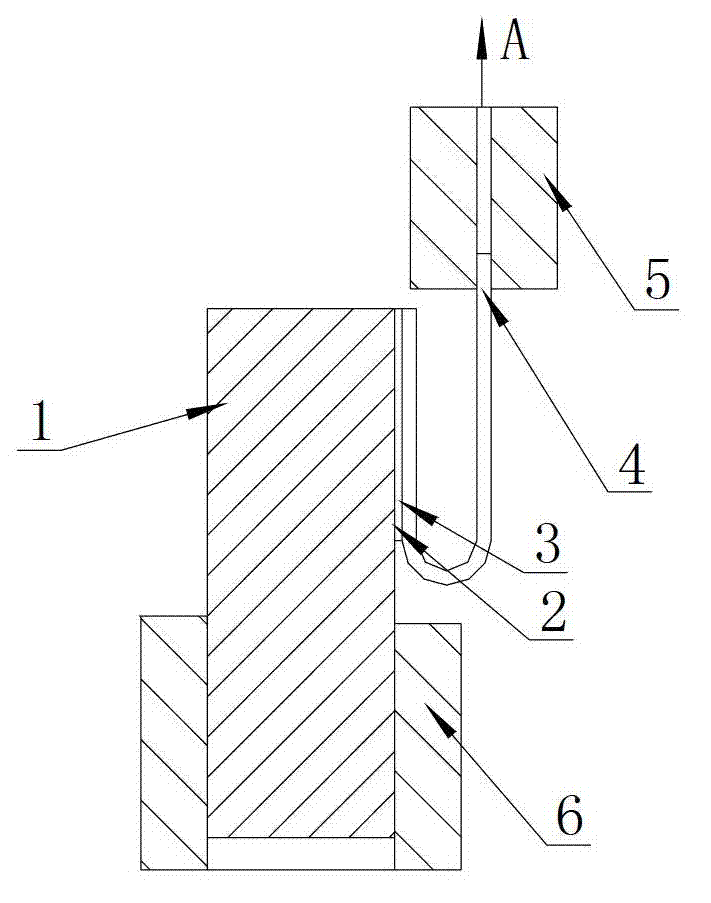

[0015] Take a steel plate as the test base plate, wipe the test plate with a degreasing gauze dipped in alcohol, and then dry it with a clean degreasing gauze. Repeat this process for more than three times until the working surface of the test plate is clean through visual inspection; The clean surface is glued with transparent glue, and one side of the 70mm x 25mm wide double-sided tape is pasted on the transparent glue of the test plate to ensure that the paste is tight, smooth, and wrinkle-free; use the conventional method to coat the positive electrode slurry on the aluminum foil current collector After baking and rolling, cut the pole piece to be tested into a 170mm x 25mm wide pole piece according to the test requirements, and paste the coated side of the pole piece to be tested on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com