Anti-fog optical resin lens and its preparation method

An optical resin lens and resin lens technology, applied in optics, optical components, instruments, etc., can solve the problems of poor adhesion and easy falling off of the anti-fog film layer, increase the transmittance of light, and have a good market prospect. , the effect of reducing the reflectivity of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

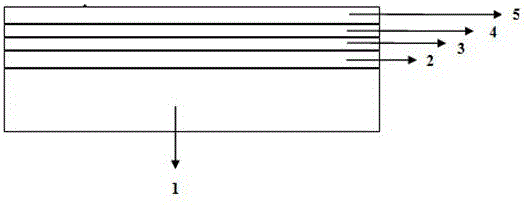

[0028] The resin lens substrate 1 is selected as bisallyl diglycol carbonate (CR39). First, after ultrasonic cleaning, the hard coat layer 2 is coated by dip coating; then, under vacuum conditions, anti-reflection anti-reflection coating Film layer 3, select the order and thickness of raw materials according to the color required by the film layer; after ultrasonic cleaning again, select polycarbonate (PC) as the polymer hydrophilic film as the anti-fog film layer 5, with a thickness of 10 microns, using optical The transparent glue OCA glue is used as the connecting glue layer 4 to adhere the PC film to the anti-reflection and anti-reflection film layer 3 and cure at room temperature.

Embodiment 2

[0030] The resin lens substrate 1 is selected as unsaturated acrylic ester, first, after ultrasonic cleaning, the hard coat layer 2 is coated by dip coating; then, the anti-reflection and anti-reflection film layer 3 is plated under vacuum conditions, and according to the film layer Select the order and thickness of raw materials for the required color; after ultrasonic cleaning again, select polyethylene terephthalate (PET) as the polymer hydrophilic film as the anti-fog film layer 5, with a thickness of 50 microns, and use optically transparent glue The OCA glue is used as the connecting adhesive layer 4, and the PET film is adhered to the anti-reflection and anti-reflection film layer, and is cured at room temperature.

Embodiment 3

[0032] Select the resin lens base 1 as polyurethane, firstly, after ultrasonic cleaning, apply the hard coat layer 2 by dip coating; then, under vacuum conditions, coat the anti-reflection and anti-reflection film layer 3, according to the required color of the film layer Select the order and thickness of raw materials; after ultrasonic cleaning again, select cellulose acetate (CA) as the polymer hydrophilic film as the anti-fog film layer 5, the thickness is 30 microns, use optically transparent glue OCA glue as the connecting glue layer 4, put The CA thin film is adhered to the anti-reflection and anti-reflection coating layer and cured at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com