Flexible display device and manufacturing method thereof

A flexible display device and flexible display technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of Flexible Cover breakage, poor bending resistance of flexible display devices, and cracking of optical transparent glue, achieving Solve cracking, improve bending resistance, and increase adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

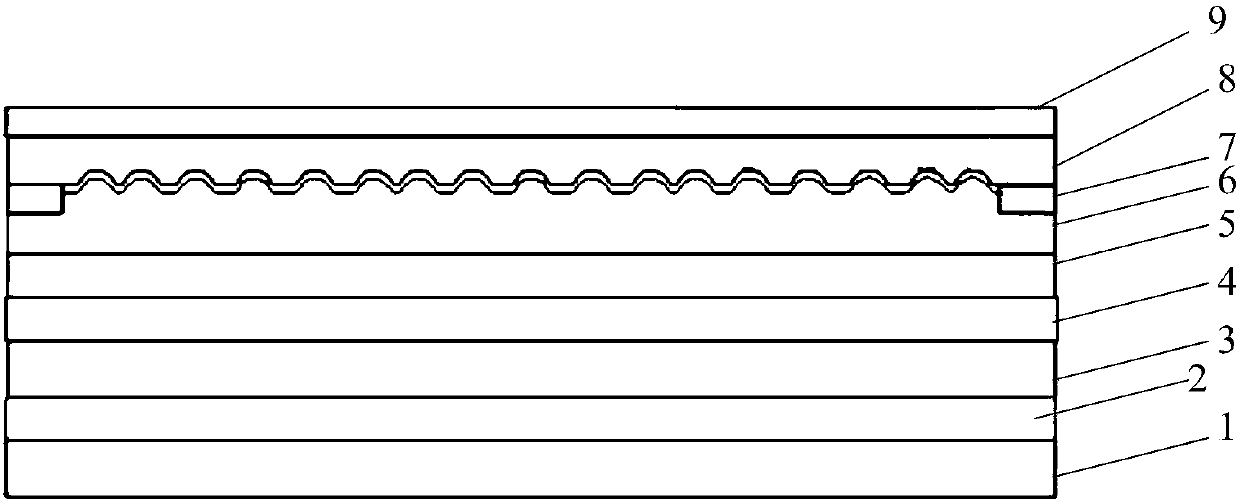

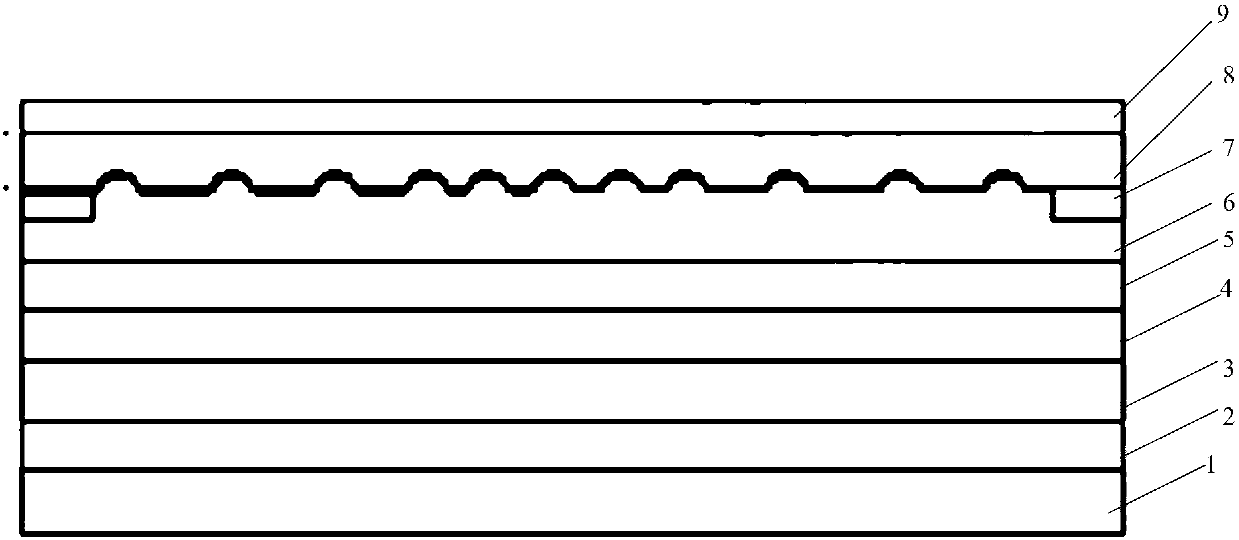

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0045] In the prior art, when the flexible AMOLED display device is folded, due to the stress between the film layers, it is easy to cause cracking and delamination of the optically transparent adhesive between the Flexible Cover and the touch panel, especially in the bending area. In severe cases, the Flexible Cover may break, making the flexible display device less capable of bending.

[0046] At present, the general method in the industry to improve the adhesion between the Flexible Cover and the optically clear glue is to use surface chemical treatment or surface plasma treatment, but these methods are not enough to deal with and completely solve the above-mentioned optical transparency between the Flexible Cover and the touch panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com