Method for preparing graphene blocks and graphene blocks prepared by same

A technology of graphene and graphene film, which is applied in the field of electronic materials, can solve the problems of limited application, high price, and complex preparation process of highly oriented pyrolytic graphite, and achieve the effects of wide application, low price, and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

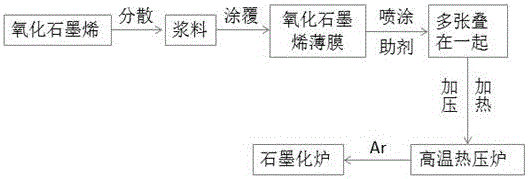

Method used

Image

Examples

Embodiment 1

[0018] Disperse 1 kg of graphene oxide in 99 kg of water to prepare a graphene oxide slurry with a solid content of 1%; sieve the prepared slurry to remove air bubbles, then use a coating device to coat 3 mm, and dry to obtain a 30 μm thick Graphene oxide film; spray polysiloxane on both sides of the dry graphene oxide film; then cut into 150mm×150mm squares, stack 1000 pieces together; , heated to 1500°C; use the graphitization furnace to heat the block obtained above to 2900°C for graphitization; finally obtain a highly oriented graphene heat conduction block of 150mm×150mm×6mm, with a density of 2.2g / cm3, heat conduction The coefficient reaches 1500W / m·K.

Embodiment 2

[0020] Disperse 3kg of graphene oxide in 97kg of NMP to prepare a graphene oxide slurry with a solid content of 3%; sieve the prepared slurry to remove air bubbles, then use a coating equipment to coat 3mm, and dry to obtain a 100μm thick graphene oxide film; spray TiO2 on both sides of the dry graphene oxide film; then cut into 150mm×150mm squares, 1000 pieces stacked together; Heating to 1700°C; heat the block obtained above to 3000°C in a graphitization furnace for graphitization; finally obtain a highly oriented graphene heat conducting block of 150mm×150mm×18mm, with a density of 2.2g / cm3 and a thermal conductivity of Up to 1500W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com