Method for preparing ultra-thin two-dimension graphite sheet

A graphite sheet, ultra-thin technology, applied in the field of nanotechnology and new materials, can solve the problem of difficult separation and removal of polymer organic glue, and achieve the effect of clean surface, simple method and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

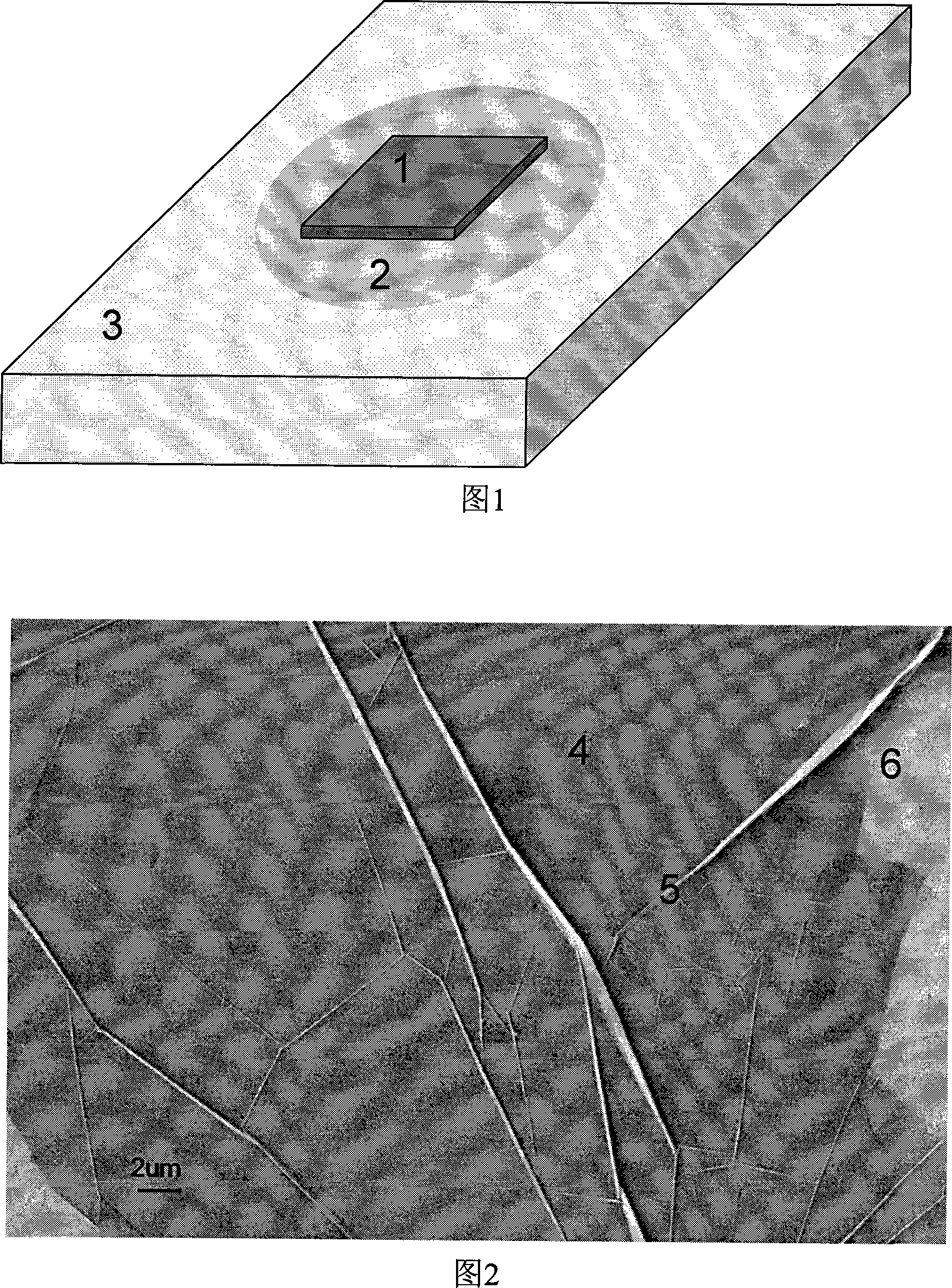

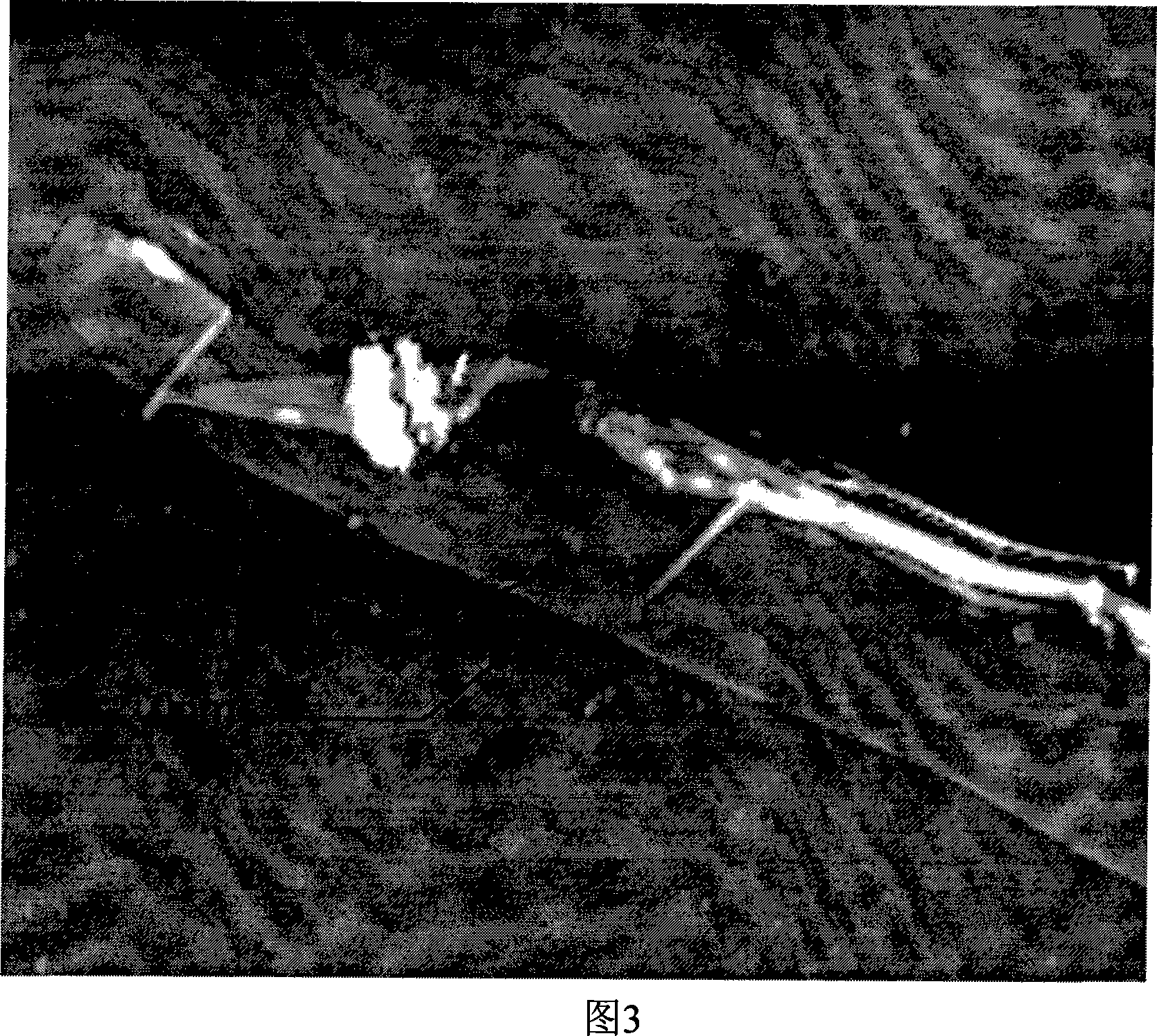

[0025] 1. Prepare a flat (111) oriented silicon single crystal polished epitaxial substrate covered by a thermal silicon oxide film with a thickness of 300 nm as a substrate. Ultrasonic cleaning with acetone for 3 times, 5 minutes each time, to clean the surface of the substrate; after drying, etch with oxygen plasma for 5 minutes, to remove the acetone molecules adsorbed on the surface.

[0026] 2. Drop a small amount of ultrapure water on the cleaned substrate. Since silicon dioxide is hydrophilic, the ultrapure water will spread itself into a water film. Control the amount of dripping water so that the thickness of the water film is within 0.1 mm .

[0027] 3. Take a piece of A-grade highly oriented pyrolytic graphite (HOPG), stick the surface graphite off with tape, and expose a new clean (0001) surface. It is required that the exposed surface should not be too flat, preferably as rough as a scale.

[0028] 4. Put the graphite in step 3 on the substrate with water film in...

Embodiment 2

[0038] 1. Prepare a flat (111) silicon single crystal polished epitaxial substrate as a substrate. Ultrasonic cleaning with acetone for 3 times, each time for 5 minutes, to clean the surface of the substrate; after drying, etch with oxygen plasma for 5 minutes, to remove the acetone molecules adsorbed on the surface.

[0039] 2. Control the temperature of the refrigerator to -20°C. Place the cleaned substrates in the freezer for 30 minutes. Take it out and place it at room temperature, a film of condensed water will naturally deposit on the substrate.

[0040] 3. Take a piece of highly oriented pyrolytic graphite, clean its surface, then take a piece of fresh tape, press and stick it on the clean graphite surface, stick some flake graphite to the tape, and then take a few clean new pieces Tape repeatedly thins the graphite on the original tape several times.

[0041] 4. Put the fresh graphite chips adhering to the adhesive tape on the substrate with water film, so that the ...

Embodiment 3

[0051] 1. Prepare a flat piece of glass as the substrate. Ultrasonic cleaning with acetone 3 times, 5 minutes each time, to clean the surface of the substrate; after drying, etch with oxygen plasma for 5 minutes, to remove the acetone molecules adsorbed on the surface.

[0052] 2. Control the temperature of the refrigerator to -17°C. Place the cleaned substrates in the freezer for 30 minutes. Take it out and place it at room temperature, a film of condensed water will naturally deposit on the substrate.

[0053] 3. Take a piece of A-grade highly oriented pyrolytic graphite (HOPG), etch its surface with oxygen plasma to carve a raised platform with a square of 10 microns and a height of 5 microns.

[0054] 4. Put the etched graphite on the substrate with a water film, so that the new clean cleaved surface of the graphite protrusion is in full contact with the water film.

[0055] 5. Put the sample in step 4 into the refrigerator to freeze for about 25 minutes, so that the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com