Preparation method of highly oriented pyrolytic graphite

A technology of pyrolytic graphite and pyrolytic graphite plate, which is applied in the field of preparation of new carbon materials, can solve the problems that the performance parameters are not as good as single crystal graphite, and the degree of crystal orientation is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

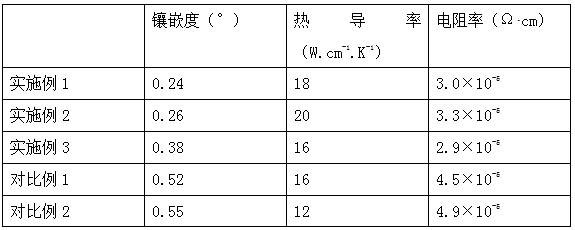

Examples

Embodiment 1

[0021] (1) Soak a rectangular and circular graphite substrate in the pretreatment solution. After soaking for 30 minutes, take it out, dry it, and then put it in a chemical vapor deposition furnace. Methane and nitrogen, the gas flow ratio is 1:2, and a 1mm pyrolytic graphite plate is deposited on the surface of the graphite substrate;

[0022] The pretreatment liquid is composed of methyltrichlorosilane, triethanolamine, and ethanol in a volume ratio of 0.5:1:20;

[0023] (2) When the pyrolytic graphite plate is cooled to 700°C, put it into a magnetic field with a magnetic field strength of 10000A / m and a magnetic field frequency of 130Hz, and take it out when the temperature drops to 150°C;

[0024] (3) Cut the pyrolytic graphite plate into square pyrolytic graphite pieces of 30*30*1mm, place the pyrolytic graphite pieces in a high-temperature and high-pressure furnace, and pass in argon gas, under the conditions of a pressure of 30MPa and a temperature of 3000°C Next, heat...

Embodiment 2

[0026] (1) Soak a rectangular and circular graphite substrate in the pretreatment solution. After soaking for 30 minutes, take it out and dry it, and then put it in a chemical vapor deposition furnace. Methane and nitrogen, the gas flow ratio is 1:2, and a 1mm pyrolytic graphite plate is deposited on the surface of the graphite substrate;

[0027] (2) When the pyrolytic graphite plate is cooled to 750°C, put it into a magnetic field with a magnetic field strength of 8000A / m and a magnetic field frequency of 120Hz, and take it out when the temperature drops to 100°C;

[0028] (3) Cut the pyrolytic graphite plate into square pyrolytic graphite pieces of 30*30*1mm, place the pyrolytic graphite pieces in a high-temperature and high-pressure furnace, and pass in argon gas, under the conditions of a pressure of 30MPa and a temperature of 3500°C Next, heat-treat the pyrolytic graphite, and the heat-treatment time is 100 minutes.

Embodiment 3

[0030] (1) Soak a rectangular and circular graphite substrate in the pretreatment solution. After soaking for 30 minutes, take it out, dry it, and then put it in a chemical vapor deposition furnace. Methane and nitrogen, the gas flow ratio is 1:2, and a 1.5mm pyrolytic graphite plate is deposited on the surface of the graphite substrate;

[0031] The pretreatment liquid is composed of methyltrichlorosilane, triethanolamine, and ethanol in a volume ratio of 0.5:1:20;

[0032] (2) When the pyrolytic graphite plate is cooled to 700°C, put it into a magnetic field with a magnetic field strength of 12000A / m and a magnetic field frequency of 150Hz, and take it out when the temperature drops to 150°C;

[0033] (3) Cut the pyrolytic graphite plate into square pyrolytic graphite pieces of 30*30*1mm, place the pyrolytic graphite small pieces in a high-temperature and high-pressure furnace, and pass in argon gas under the conditions of a pressure of 30MPa and a temperature of 2500°C Nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com