Composite film with high electrochemical performance and preparation method of composite film

An electrochemical and composite membrane technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of affecting assembly quality, complex assembly process, and high equipment requirements, and achieve excellent electrochemical performance, low preparation cost, and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

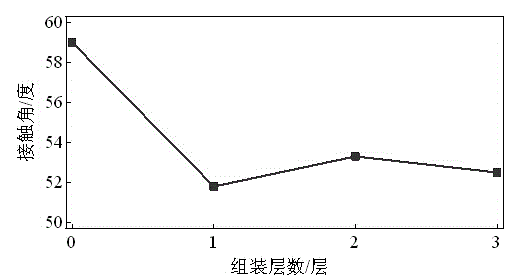

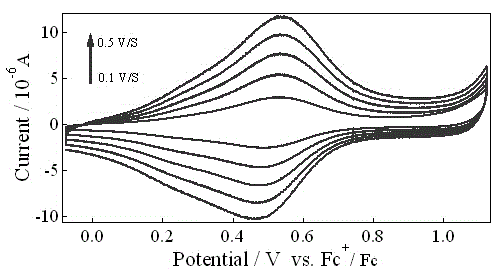

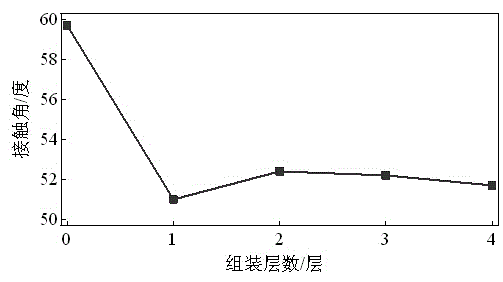

[0039] Example 1: This high electrochemical performance composite film is that the pyrene group in the amphiphilic ruthenium complex molecule self-assembles to the surface of highly oriented pyrolytic graphite through the action of non-covalent bonds, and then the self-assembled highly oriented pyrolysis The graphite substrate is repeatedly and alternately immersed in the zirconium oxychloride solution and the symmetrical ruthenium complex solution, and the amphiphilic ruthenium complex molecules and the symmetrical ruthenium complex molecules, as well as the symmetrical ruthenium complex molecules are connected by zirconium ions , to obtain a composite film with high electrochemical performance with adjustable layers and thickness; the chemical formula of the amphiphilic ruthenium complex is as follows:

[0040] ;

[0041] The chemical formula of the symmetrical ruthenium complex is as follows:

[0042] .

[0043] The specific steps of the method for preparing a compos...

Embodiment 2

[0068] Example 2: This high electrochemical performance composite film is that the pyrene group in the amphiphilic ruthenium complex molecule self-assembles to the surface of highly oriented pyrolytic graphite through the action of non-covalent bonds, and then the highly oriented pyrolytic graphite after self-assembly is The graphite substrate is repeatedly and alternately immersed in the zirconium oxychloride solution and the symmetrical ruthenium complex solution, and the amphiphilic ruthenium complex molecules and the symmetrical ruthenium complex molecules, as well as the symmetrical ruthenium complex molecules are connected by zirconium ions , to obtain a composite membrane with high electrochemical performance with adjustable layers and thickness; the chemical formula of the amphiphilic ruthenium complex is as follows:

[0069] ;

[0070] The chemical formula of the symmetrical ruthenium complex is as follows:

[0071] .

[0072] The specific steps of the method ...

Embodiment 3

[0082] Example 3: This high electrochemical performance composite film is that the pyrene group in the amphiphilic ruthenium complex molecule self-assembles to the surface of highly oriented pyrolytic graphite through the action of non-covalent bonds, and then the self-assembled highly oriented pyrolysis The graphite substrate is repeatedly and alternately immersed in the zirconium oxychloride solution and the symmetrical ruthenium complex solution, and the amphiphilic ruthenium complex molecules and the symmetrical ruthenium complex molecules, as well as the symmetrical ruthenium complex molecules are connected by zirconium ions , to obtain a composite film with high electrochemical performance with adjustable layers and thickness; the chemical formula of the amphiphilic ruthenium complex is as follows:

[0083] ;

[0084] The chemical formula of the symmetrical ruthenium complex is as follows:

[0085] .

[0086] The specific steps of the method for preparing a compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com