Method for macroscopic super-lubricity of friction surface grown graphene

A technology of friction surface and graphene, which is applied in the field of macroscopic lubrication, can solve problems such as the difficulty of achieving macroscopic super-slip on the surface, the application of mechanical moving parts, etc., and achieve the effect of reducing the friction coefficient and friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

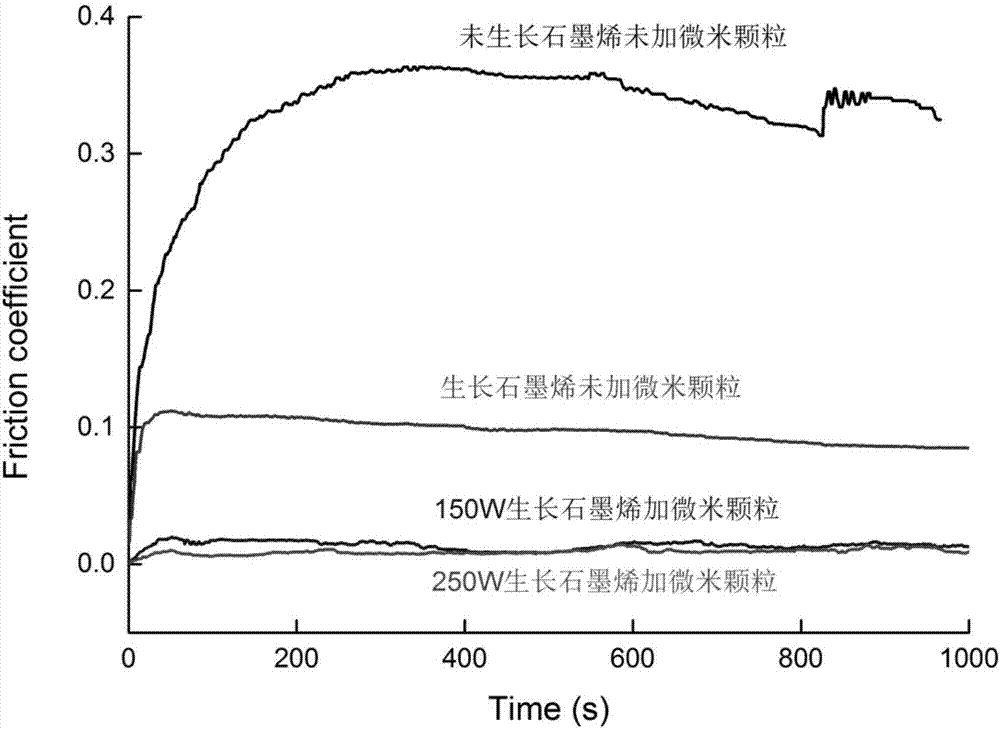

Embodiment 1

[0032]The quartz friction pair was ultrasonically cleaned with acetone and dried for 10 minutes; the friction pair was placed in a plasma-enhanced chemical vapor deposition equipment quartz furnace tube, and the temperature was raised to 800 °C within 50 minutes under a hydrogen (20 sccm) atmosphere. The radio frequency power is adjusted to 250W, and the methane precursor (16sccm) is passed through to grow graphene. The growth time is 30min; the growth is completed, cooled to room temperature, and the friction pair is taken out; The amplitude is 2 mm, the swing frequency is 0.1 Hz, the host is started, and the measured friction coefficient is 0.15. The measured friction coefficient is 0.35 under the condition that no graphene is grown and no micron particles are added.

Embodiment 2

[0034] The quartz friction pair and lubricating particles were ultrasonically cleaned with acetone, and the ultrasonic cleaning time was 10 min; the friction pair and lubricating particles were placed in the quartz furnace tube of plasma-enhanced chemical vapor deposition equipment respectively, and the average particle size of the lubricating particles was 10 μm. ) atmosphere within 50 minutes, the temperature was raised to 800°C, the radio frequency power was adjusted to 150W, and the methane precursor (16sccm) was introduced to grow graphene. The growth time was 30 minutes; the growth was completed, cooled to room temperature, and the friction pair and lubricating particles were taken out , evenly distribute the lubricating particles on the surface of the friction pair; place the friction pair on the testing machine, adjust the pressure to 50mN, swing amplitude 2mm, swing frequency 0.1Hz, start the host, and the measured friction coefficient is 0.01.

Embodiment 3

[0036] The quartz friction pair and lubricating particles were ultrasonically cleaned with acetone, and the ultrasonic cleaning time was 10 min; the friction pair and lubricating particles were placed in the quartz furnace tube of plasma-enhanced chemical vapor deposition equipment respectively, and the average particle size of the lubricating particles was 10 μm. ) atmosphere within 50 minutes, the temperature was raised to 800°C, the radio frequency power was adjusted to 250W, and the methane precursor (16sccm) was introduced to grow graphene, and the growth time was 30 minutes; the growth was completed, cooled to room temperature, and the friction pair and lubricating particles were taken out , evenly distribute the lubricating particles on the surface of the friction pair; place the friction pair on the testing machine, adjust the pressure to 50mN, swing amplitude 2mm, swing frequency 0.1Hz, start the host, and the measured friction coefficient is 0.005.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com