Unsaturated organic matter circulating hydrogenation and energy storage device

An organic matter, hydrogen energy storage technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of high practical operation risk, large evaporation loss, low pressure resistance, etc. , to achieve the effect of high target yield and safety, low environmental pollution and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

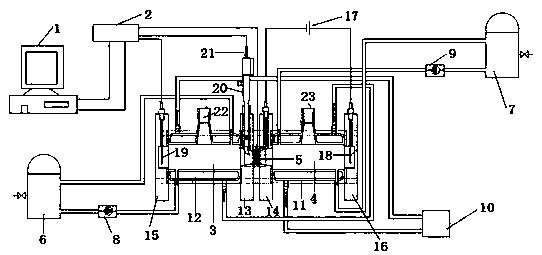

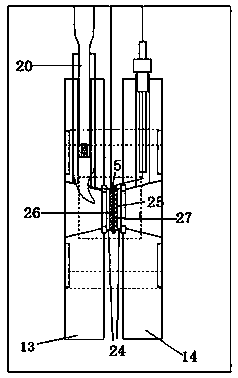

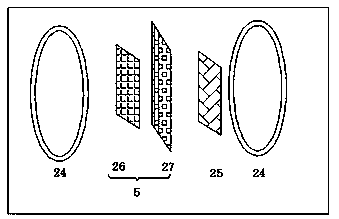

[0027]An energy storage device for circulating hydrogenation of unsaturated organic matter, comprising a computer 1, an electrochemical workstation 2, a cathode reaction chamber 3, an anode reaction chamber 4, SPEME5, a liquid storage tank I6, and a liquid storage tank III7. The SPEME5 is composed of a catalytic layer 26 Constituted with Nafion membrane 27, GFCE25 is located on the other side of Nafion membrane 27; HOPGE II19 is fixed on one side of cathode reaction chamber 3 through polyvinyl chloride splint III15, and HOPGEI18 is fixed on one side of anode reaction chamber 4 through polyvinyl chloride splint IV16 , SPEME5 is located between the PVC splint I13 and the PVC splint II14, and the place where SPEME5 contacts the PVC splint I13 and the PVC splint II14 is provided with an O-ring 24; the PVC splint IV16, the PVC splint II14, polyvinyl chloride splint I13, and polyvinyl chloride splint III15 are provided with four screw holes 28, and are arranged in sequence, and four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com