Method for preparing high-quality graphite monocrystal

A high-quality, graphite technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of high preparation temperature, and achieve the effect of simple operation, simple process flow and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Prepare the premix

[0032] Take 0.3 grams of high-purity carbon powder (purity>99%) and 11 grams of nickel powder (purity>99%) and mix evenly.

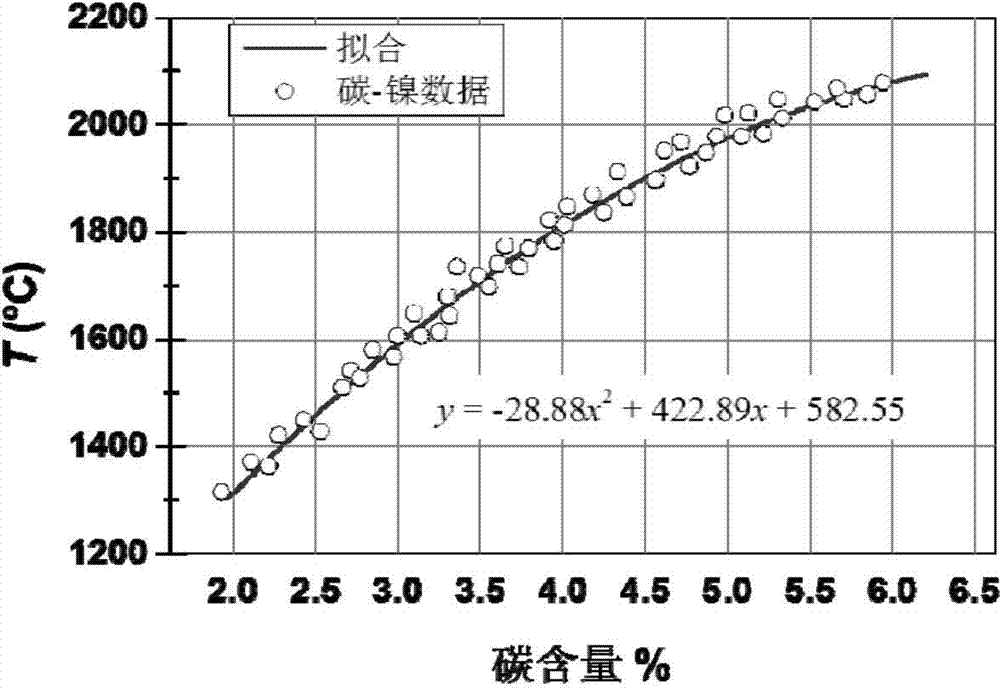

[0033] (2) heat treatment

[0034] The mixture was put into an alumina crucible, and the crucible was placed in a muffle furnace. The muffle furnace was evacuated and filled with argon gas for three times, and finally the sample was protected by argon gas. Substitute the ratio in step (1) into the formula to get (-28.88x 2 +422.89x+582.55)=1501.7°C, so the temperature in the furnace is raised to 1510°C, and kept at this temperature for 30 minutes.

[0035] (3) cooling

[0036] The muffle furnace was cooled to 500°C at a rate of 1°C / min, and then cooled to room temperature naturally.

[0037] (4) Separation of graphite

[0038] The sample is taken out from the alumina crucible, and the obtained material has two layers, the upper layer and the upper layer are graphite products after mechanical peeling.

[0039] (5) Sam...

Embodiment 2

[0042] (1) Prepare the premix

[0043] Take 1 gram of coke (carbon content>99%) and 30 grams of cobalt oxide (purity>99.5%, wherein the content of cobalt element is 23.6 grams) and mix evenly.

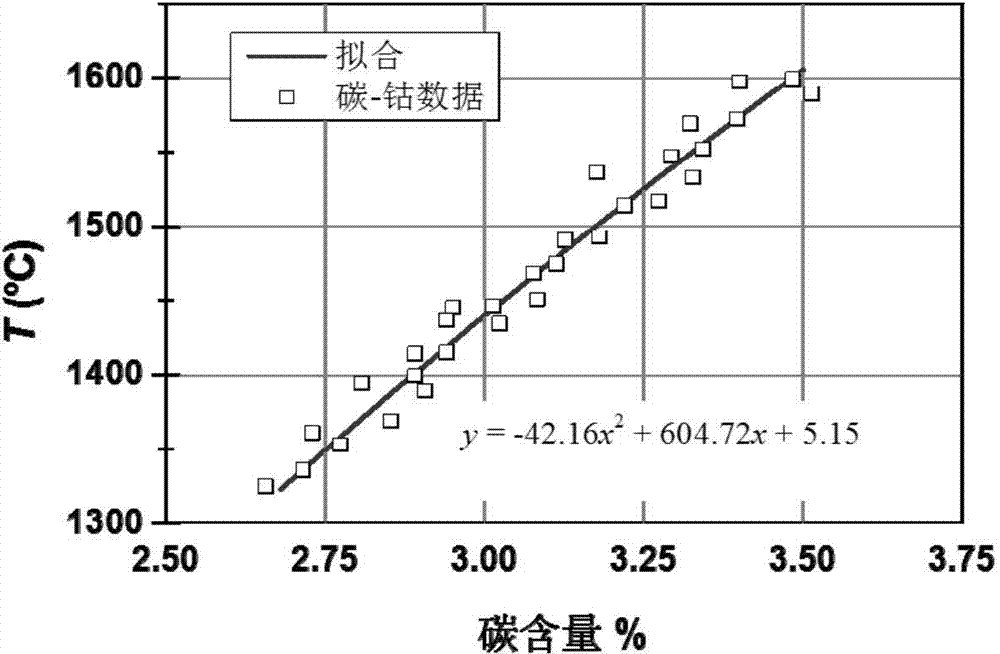

[0044] (2) heat treatment

[0045] The mixture was put into an alumina crucible, and the crucible was placed in a muffle furnace. The muffle furnace was evacuated and filled with argon gas for three times, and finally the sample was protected by argon gas. Substitute the ratio in step (1) into the formula to get (-42.16x 2 +604.72x+5.15)=1777.1°C, so the temperature in the furnace is raised to 1900°C, and kept at this temperature for 60 minutes.

[0046] (3) cooling

[0047] The muffle furnace was cooled to 500°C at a rate of 1°C / min, and then cooled to room temperature naturally.

[0048] (4) Separation of graphite

[0049] The sample is taken out from the alumina crucible, and the obtained material has two layers, the upper layer and the upper layer are graphite products after m...

Embodiment 3

[0053] (1) Prepare the premix

[0054] Take 5 grams of asphalt (carbon content>99%) and 250 grams of ferrous nitrate (purity>99.5%, wherein the iron element content is 77.8 grams) and mix evenly.

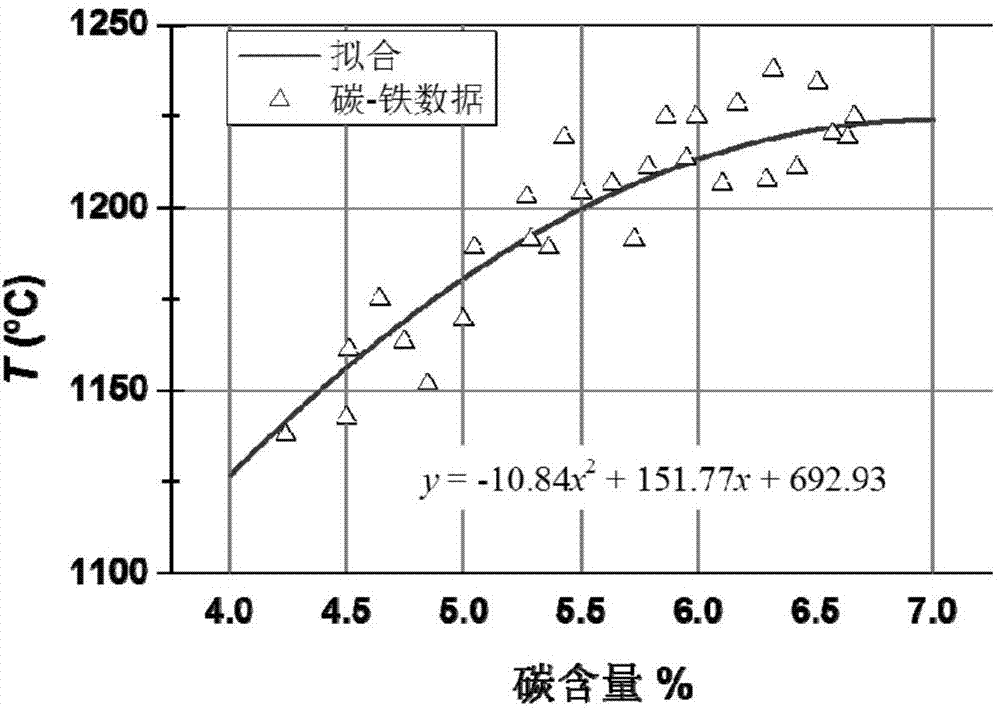

[0055] (2) heat treatment

[0056] The mixture was put into an alumina crucible, and the crucible was placed in a muffle furnace. The muffle furnace was evacuated and filled with argon gas for three times, and finally the sample was protected by argon gas. Substitute the ratio in step (1) into the formula to get (-10.84x 2 +151.77x+692.93)=1214.1°C, so the temperature in the furnace is raised to 1220°C, and kept at this temperature for 90 minutes.

[0057] (3) cooling

[0058] The muffle furnace was cooled to 500°C at a rate of 1°C / min, and then cooled to room temperature naturally.

[0059] (4) Separation of graphite

[0060] The sample is taken out from the alumina crucible, and the obtained material has two layers, the upper layer and the upper layer are graphite products af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diffraction angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com