Method for preparing contact lens having polymer multilayer film

A contact lens, polymer film technology, applied in glasses/goggles, optics, instruments, etc., can solve problems such as poor adhesion, achieve high water content, improve comfort, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention are further described below through specific examples, which do not represent limitations to the protection scope of the present invention. Some non-essential modifications and adjustments made by others according to the concept of the present invention still belong to the protection scope of the present invention.

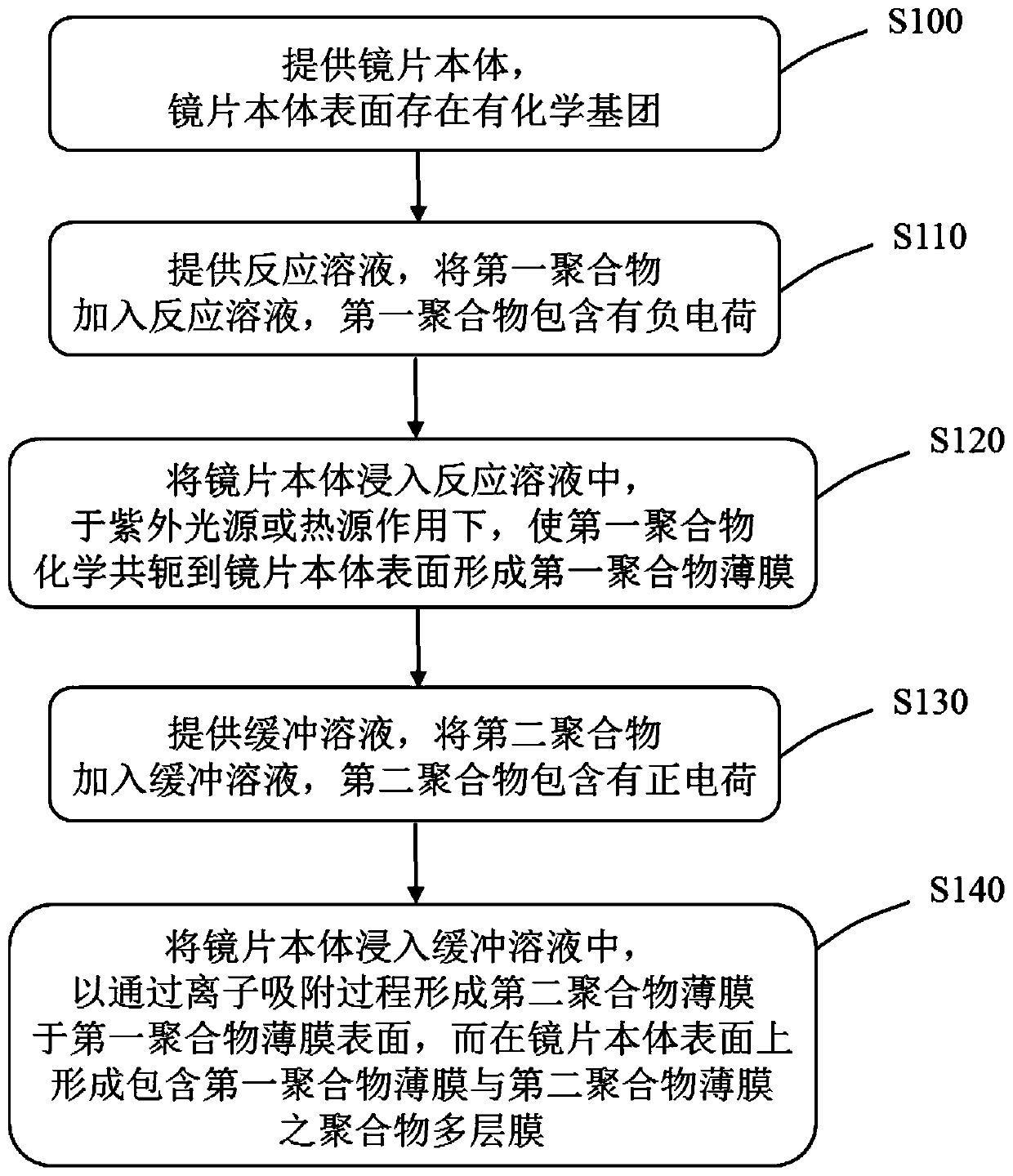

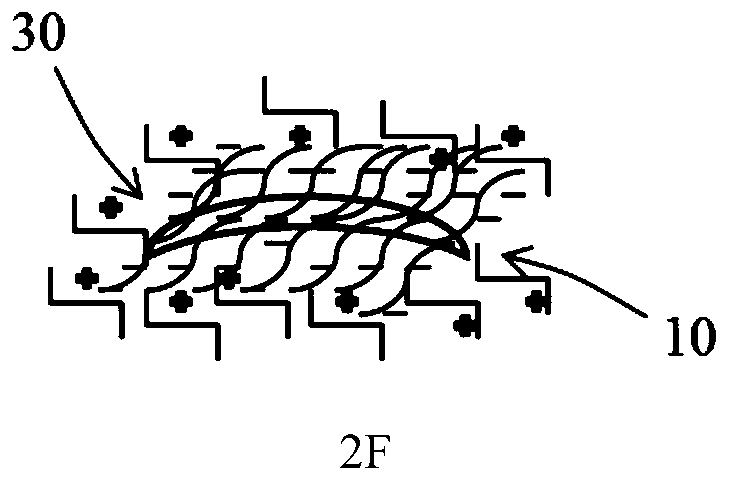

[0020] Please refer to Figure 1 to illustrate the process steps of the preparation method of the contact lens with polymer multilayer film provided by the present invention; Schematic flow chart of the preparation method of the multilayer contact lens.

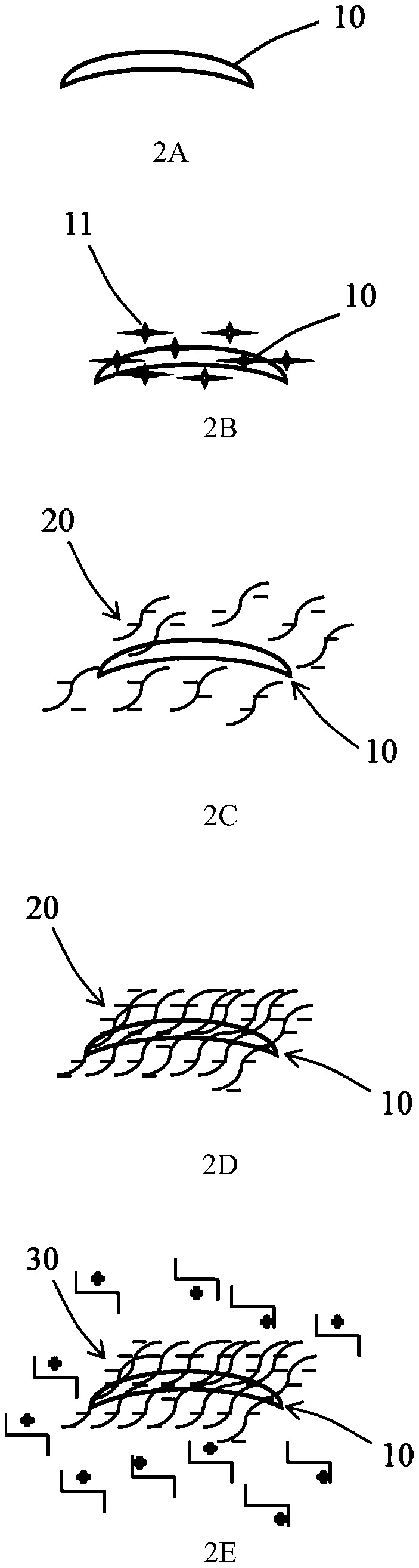

[0021] First, see step S100, as shown in FIG. 2A, a lens body 10 is provided. This lens body 10 is made of a monomer rich in chemically active groups, and there are multiple active groups on the surface of the lens body 10. a chemical group.

[0022] In the present invention, contact lens refers to an optical or medical article manufactured using any of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com