Knitting method of solid knitting fabric and knitting fabric

A knitted fabric and three-dimensional technology, which is applied in the weaving of three-dimensional knitted fabrics and knitted products, can solve problems such as conspicuousness, and achieve the effect of stability and protection of knitted fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

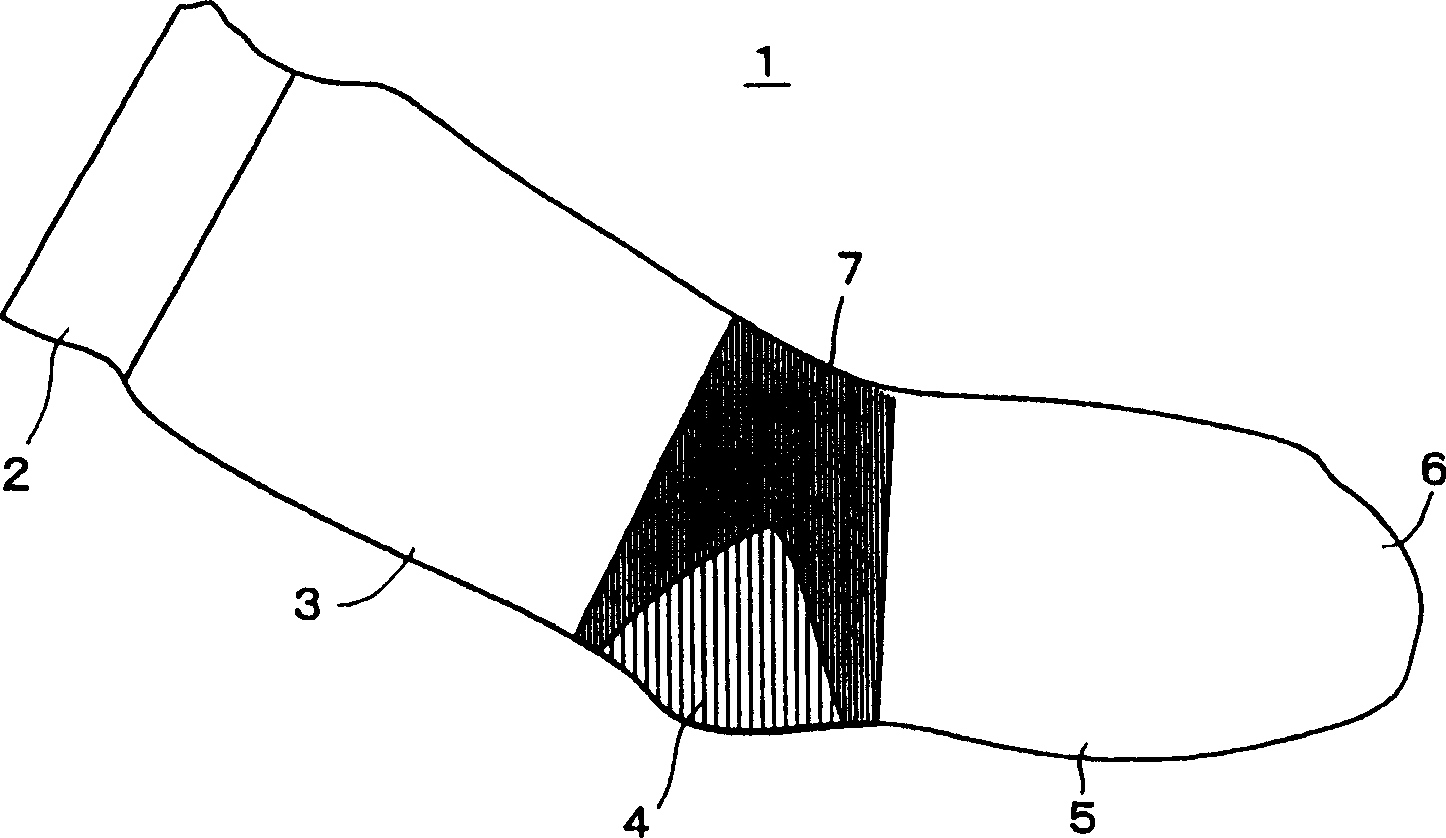

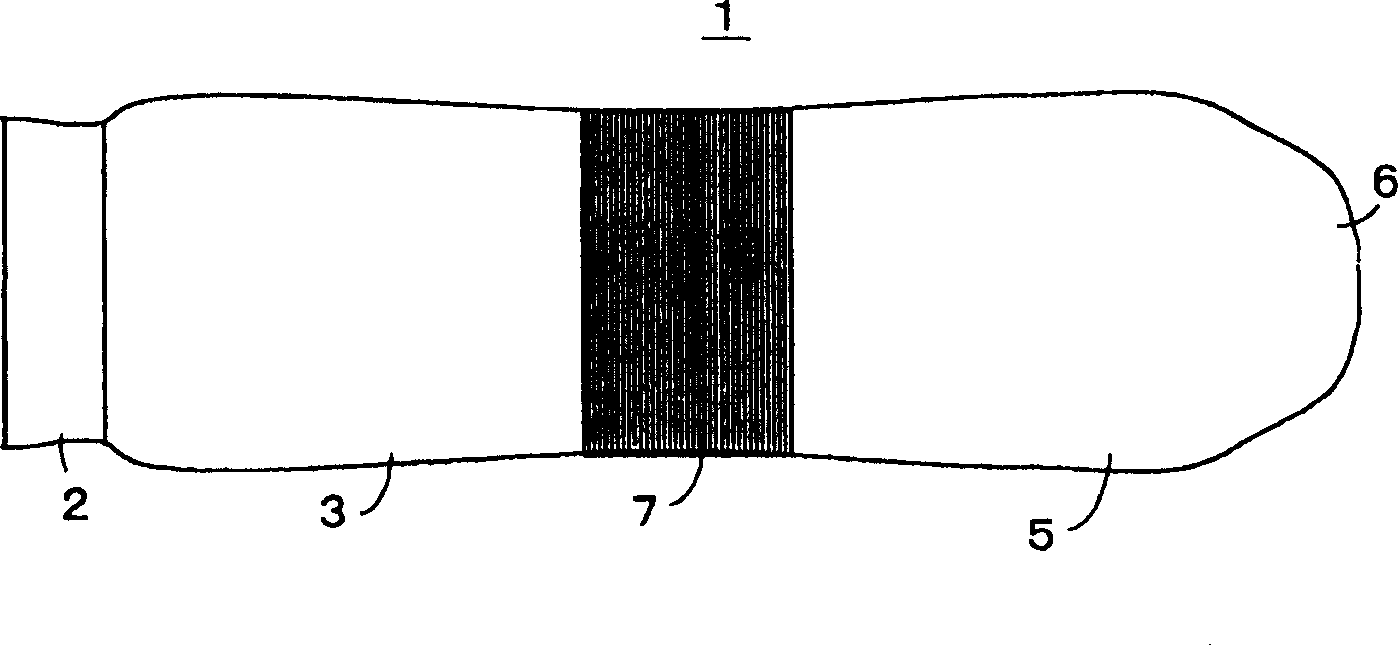

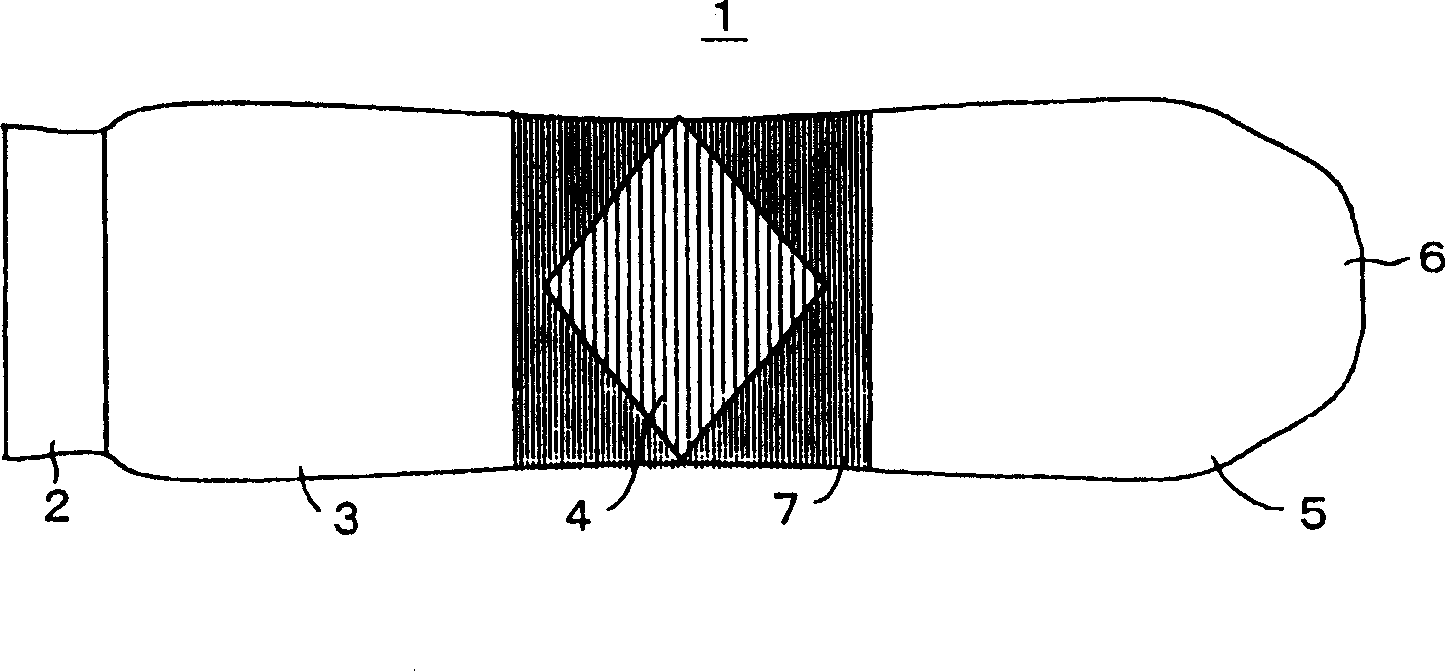

[0059] figure 1 , figure 2 as well as image 3 It is a side view showing the appearance structure of the sock 1 of the first embodiment knitted by the three-dimensional knitted fabric knitting method of the first embodiment of the present invention. figure 1 , figure 2 , image 3 Indicates the state viewed from the side, top, and bottom, respectively. The opening of the sock 1 on the human body's feet is provided with an elastic elastic part 2, which is woven by rib knitting, and an elastic thread such as rubber is used as a part of the woven thread. The leg part 3 is formed continuously with the elastic elastic part 2, and then from the heel part 4, the foot part 5 to the toe 6, is woven into a tubular knitted fabric as a whole. The leg part 3 and the leg part 5 are formed in substantially straight cylindrical shape. A heel portion 4 is provided between the foot portion 5 and the leg portion 3 , and a peripheral portion 7 is provided around the heel portion 4 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com