Wear-resistant and easily-stain-removing luggage fabric and processing method thereof

A bag fabric and easy decontamination technology, applied in chemical instruments and methods, surface pretreatment, devices for coating liquid on the surface, etc., can solve the problem of stiff hand feeling of bag fabrics, shortening the service life of bags, cracking and peeling of the glue layer, etc. problems, to achieve the effect of eliminating surface gloss, easy printing and dyeing, and smooth touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

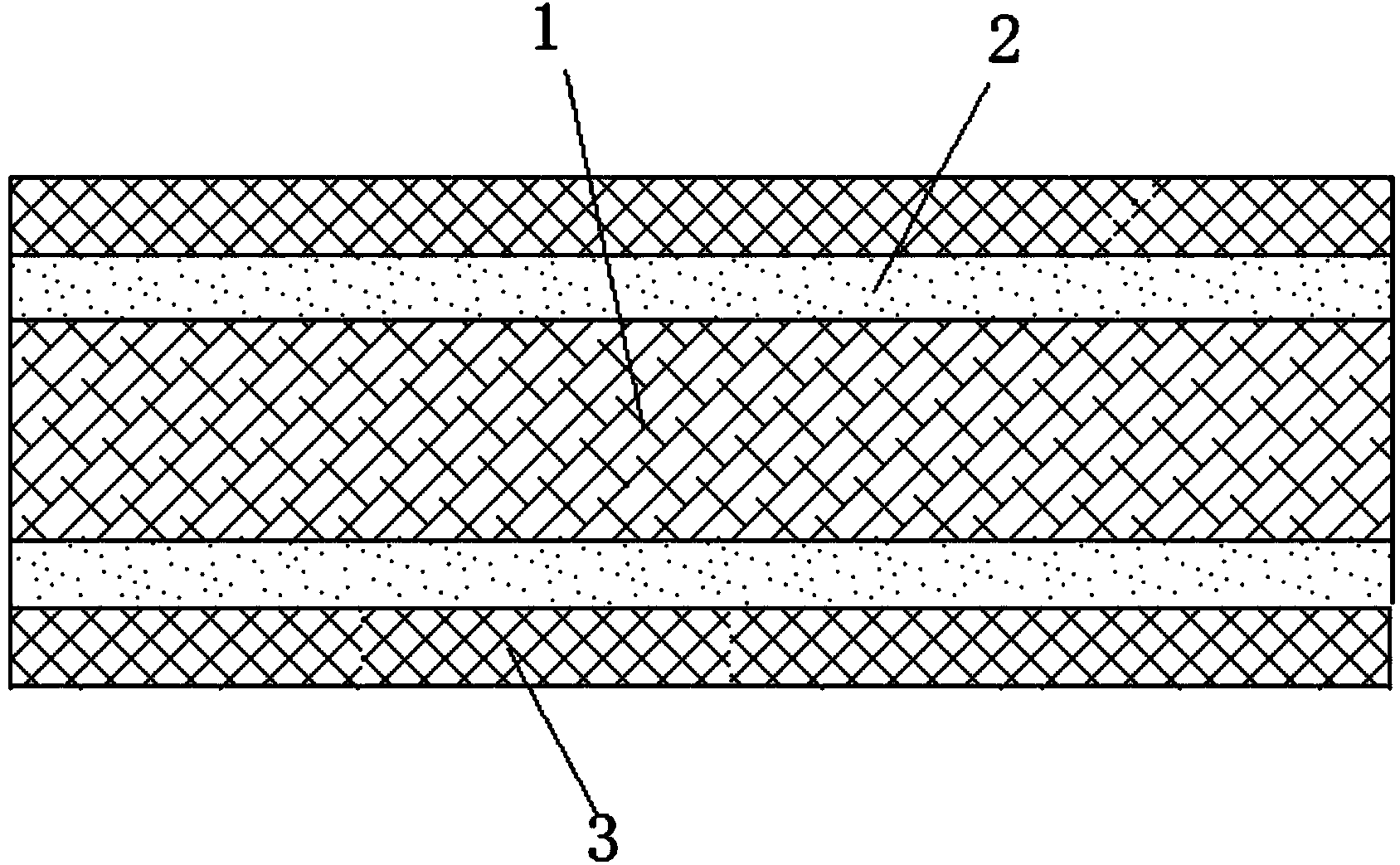

[0021] Such as figure 1 As shown, the present invention comprises a base cloth 1 of a polyester space-changing yarn (air textured yarn) fabric, and the upper and lower surfaces of the base cloth 1 are coated with a thin layer of low-modulus polyurethane adhesive layer 2 with a relatively low degree of polymerization. A thin layer of high modulus polyurethane adhesive layer 3 is coated on the surface of the upper and lower low modulus polyurethane adhesive layers 2 .

[0022] In the above-mentioned embodiment, the upper and lower surfaces of the fabric base cloth 1 are equally divided into two coatings, and the low-modulus polyurethane adhesive layer 2 coated for the first time is a primer. As an adhesive layer, its thickness is different according to the structure of the base cloth. , the dry weight gain of the low modulus polyurethane adhesive used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com