Environment-friendly high-printability non-woven wallpaper base and preparation method thereof

A high printability, wallpaper technology, used in special paper, textiles and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc. Market competitiveness and other issues, to achieve the effect of dimensional stability, no warpage, and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

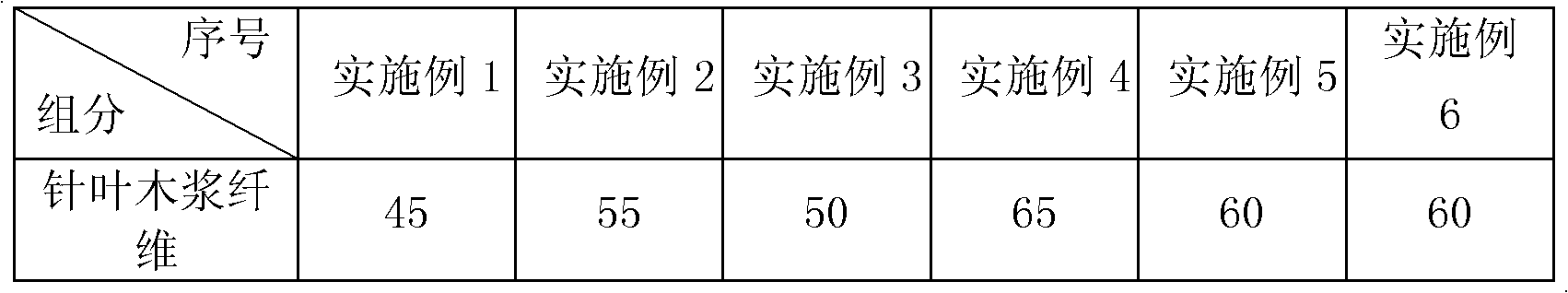

[0017] The component distribution ratio (in parts by weight, unit %) of the environmentally friendly high printability non-woven wallpaper base paper is shown in Table 1 and Table 2, and Example 3 is the best implementation mode.

[0018] Table 1 Example 1-6 Environment-friendly high printability non-woven wallpaper base paper component distribution ratio (by weight)

[0019]

[0020]

[0021] In Table 1, the fineness of polyvinyl formal fibers, polyethylene terephthalate fibers and high-strength fibers in Examples 1-6 is 1-10D, and the length is 5-20mm.

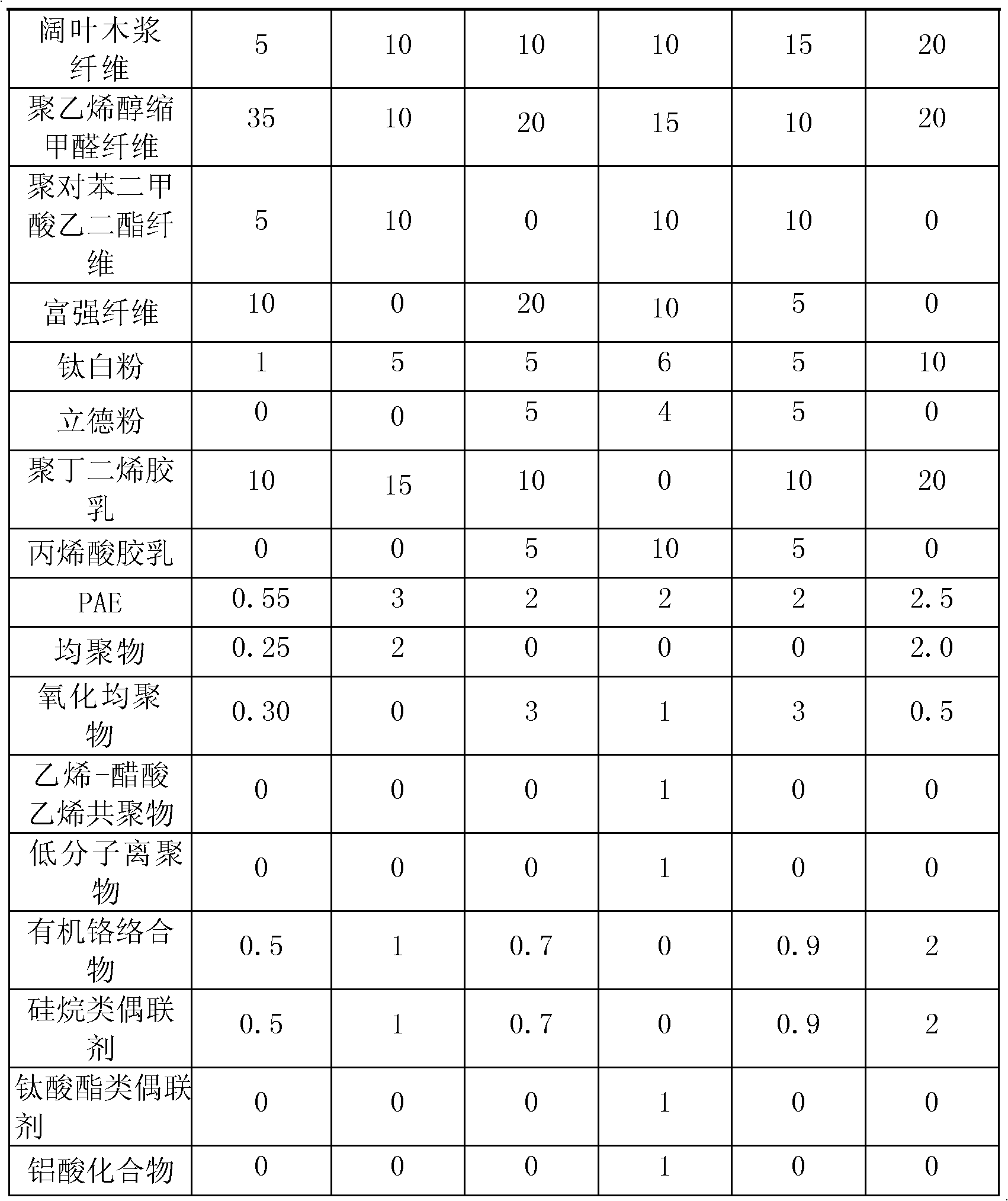

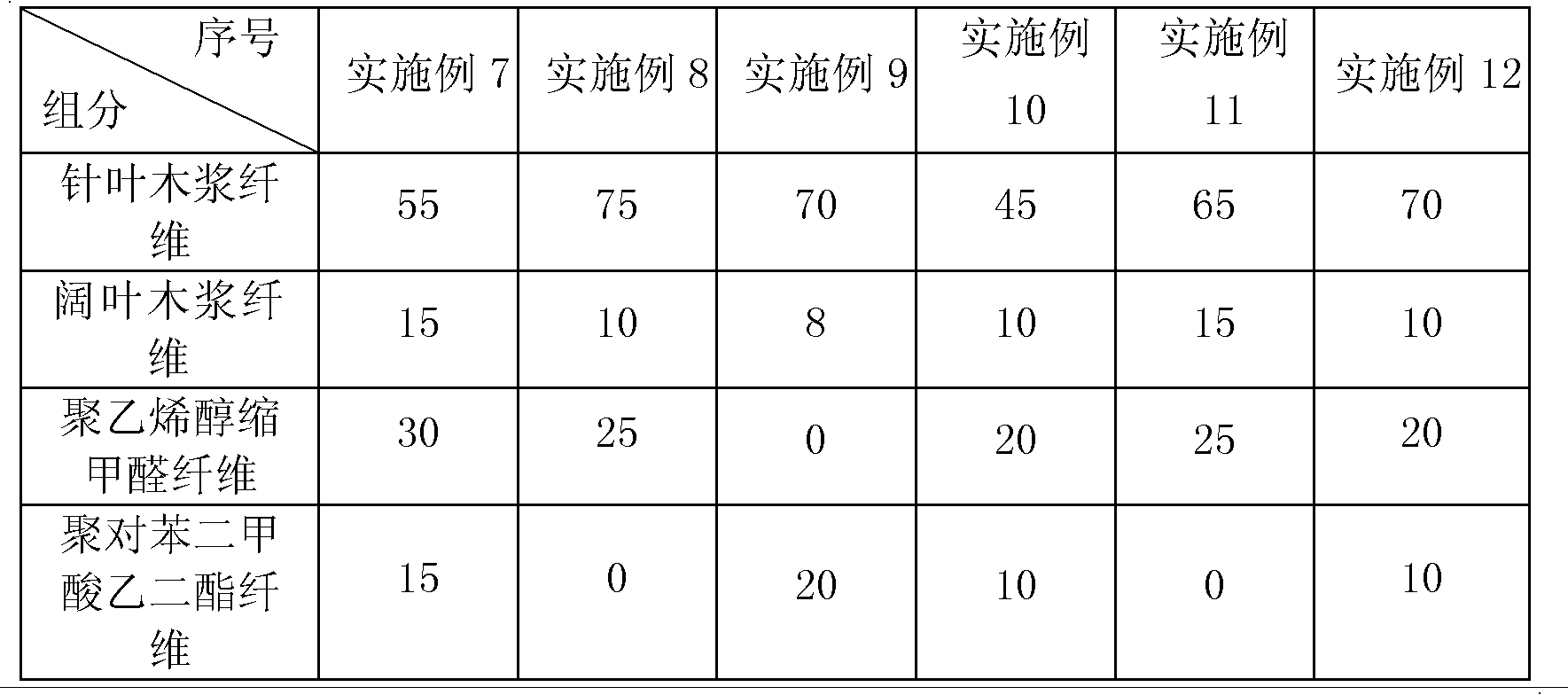

[0022] Table 2 Example 7-12 Environment-friendly high printability non-woven wallpaper base paper component distribution ratio (by weight)

[0023]

[0024]

[0025] In Table 2, the fineness of polyvinyl formal fibers, polyethylene terephthalate fibers and high-strength fibers in Examples 7-12 is 5-20D, and the length is 15-30mm.

[0026] The preparation method of embodiment 1~6 adopts following steps:

[0027]...

Embodiment 7~12

[0031] The preparation method of embodiment 7~12 adopts following steps:

[0032] a) Control the degree of beating of the coniferous plant fibers in the wood pulp fibers at 15 to 20°SR, and the broad-leaved plant fibers in the wood pulp fibers are fully dispersed by a disintegrator until the fibers are even and there are no pulp lumps, and then the two kinds of wood Pulp fiber and chemical fiber are mixed in proportion, using a pulper to finely grind, disintegrate, and beat. The beating degree is 30-32°SR, and the beating concentration is controlled at 2-5%;

[0033] b) adding inorganic fillers and chemical additives to the pulper for batching, and adjusting the pH value to 7-8 with aluminum sulfate to form a mixed fiber slurry;

[0034] c) copying and drying the mixed fiber slurry described in step b) through a fourdrinier paper machine to obtain a base paper semi-finished product;

[0035] d) The semi-finished base paper is dipped in the mixture of surface treatment agent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com