Preparation method of light and thin all-cotton non-woven fabric, non-woven fabric and application

A technology of all-cotton non-woven fabrics and non-woven fabrics, which is applied in non-woven fabrics, textiles and papermaking, fiber processing, etc. Effects of smoothness, high raw material utilization, good hygroscopicity and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

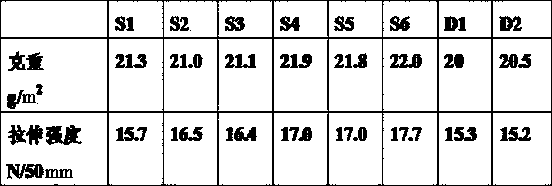

Examples

Embodiment 1

[0030] Embodiment 1 (referred to as S1, the same below)

[0031] The preparation method of embodiment 1 frivolous all-cotton nonwoven fabric, comprises the following steps:

[0032] S1, disposing cotton fiber, cleaning, carding and laying net to obtain cotton fiber web;

[0033] S2, Spunlace the cotton fiber web obtained in S1 to obtain a grammage of 20g / m 2 spunlace non-woven fabric;

[0034] S3, introducing the non-woven fabric that has been spunlace once into the lye tank for mercerizing treatment, and then exporting it to be boiled and rinsed after the liquid is squeezed;

[0035] S4, immersing the mercerized non-woven fabric with water in a cellulose ionic liquid solution at room temperature, and then spunlacing and drying for the second time after squeezing the liquid;

[0036] S5, washing with water and drying for the second time to obtain a light and thin cotton non-woven fabric product.

[0037] In Example 1, the concentration of caustic soda in the lye in S3 is 2...

Embodiment 2-3

[0039] Embodiment 2-3 is based on embodiment 1, difference is the process parameter of mercerizing process:

[0040] Example 2 The concentration of caustic soda in the lye in S3 is 250g / L, the temperature of the lye is 20°C, and the mercerizing treatment time is 20s; the tension of the non-woven fabric in the lye tank in S3 is 0.5 bar, and the liquid carrying rate in S3 is 70 %;

[0041] Example 3 The concentration of caustic soda in the lye in S3 is 260g / L, the temperature of the lye is 15°C, and the mercerizing treatment time is 30s; %;

Embodiment 4-5

[0043] The difference between embodiment 4-5 and embodiment 3 is the spunlace process condition:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com