Fabric for satin face changing cloth

A fabric and satin technology, applied in the field of changing satin fabrics, can solve problems such as stiff hand feel and limit the application of polyester fiber fabrics, and achieve the effect of increasing style highlights, adding attractive fashion charm, and imitating leather with a strong sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

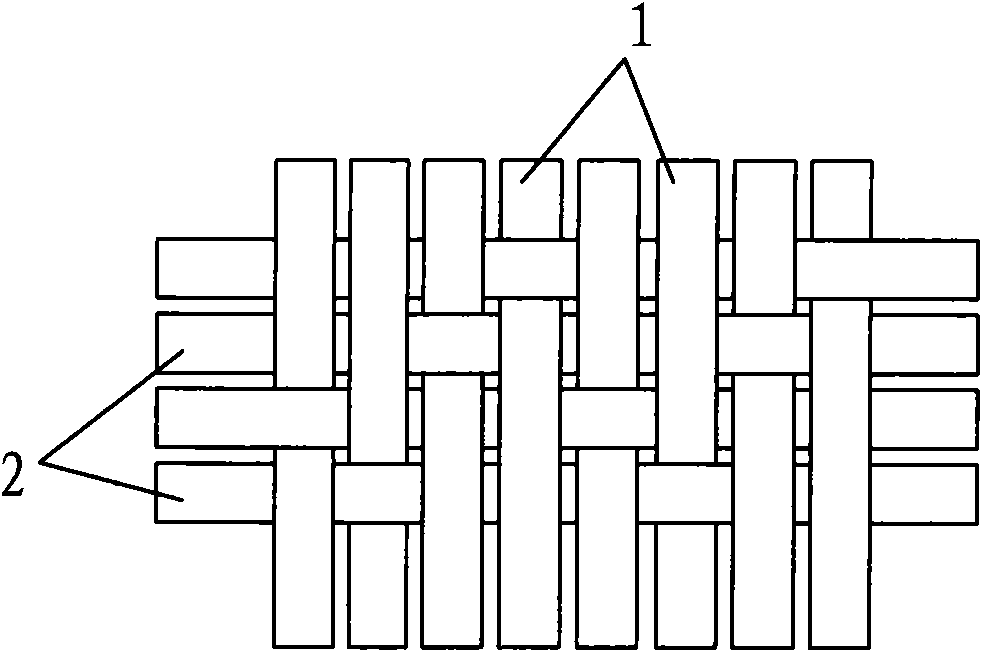

[0018] Example: as attached figure 1 A variant satin fabric is shown, interwoven with warp 1 and weft 2.

[0019] Warp 1 is 50D / 144F fully stretched polyester filament with semi-dull gloss. Weft yarn 2 is 50D / 144F fully stretched polyester filament with semi-dull gloss.

[0020] Among them, D (denier, Dani number) in 50D / 144F refers to the thickness unit of a yarn, which is expressed in grams of weight that can be weighed out of the yarn at a length of 9000 meters, also known as denier. The larger the D, the thicker the yarn. For example, 75D is thicker than 50D. F (filament, number of threads), such as 75D / 144F means that a yarn is composed of 144 spun yarns, and the total weight of a yarn with a length of 9000 meters is 75 grams. In production, in the case of the same D but different F numbers, the higher the F number, the more difficult it is to weave, and vice versa; the same F number, the lower the D number, the harder it is to weave, and vice versa. For example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com