Soundless wax-penetrating polishing agent for synthetic leather and preparation method thereof

A synthetic leather and treatment agent technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of incompatibility between hand feeling and light feeling, easy oil slick, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for synthetic leather with silent wax polishing treatment agent, comprising the steps of:

[0021] 1. Synthesis of silicone-modified polyurethane resin with 30% solid content: put 194kg of reactive silicone with a molecular weight of 2000 into a 3.8-ton reactor, add 242kg of PPG1000, add 145kg of PCL1000, add 107kg of IPDI, and add 128kg of H12MDI. Add 300kg of DMF, stir for 20 minutes, raise the temperature to 90°C-95°C for 2h, add 0.45kg of organic bismuth catalyst after 2h, keep warm and continue the reaction for 2.5h, cool down to 60°C by cooling cycle, add 1000kg of cyclohexanone, continue to cool down to 40 ℃, gradually add 82kgIPDI dropwise to increase the viscosity to 9000-10000CPS / 25℃, stop the reaction with morphine and stir for 30min, add 800kg ethyl ester and stir for 30min to unload;

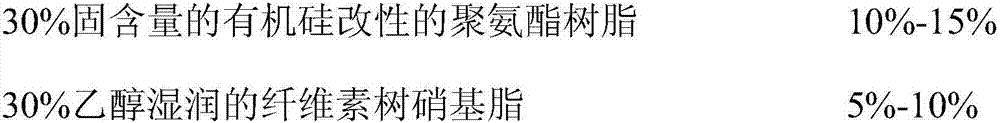

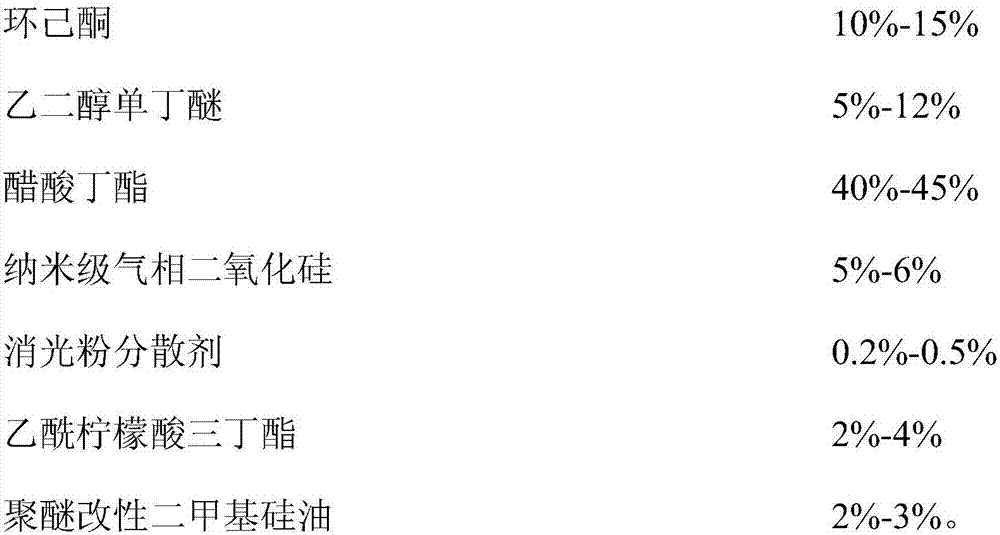

[0022] 2, compounding of treatment agent: in 3 cubic meters of biaxial dispersing kettles, add 135kg of organosilicon-modified polyurethane resins with 3...

Embodiment 2

[0025] A preparation method for synthetic leather with silent wax polishing treatment agent, comprising the steps of:

[0026] 1. Synthesis of silicone-modified polyurethane resin with 30% solid content: put 190kg of reactive silicone with a molecular weight of 2000 into a 3.8-ton reactor, add 230kg of PPG1000, add 150kg of PCL1000, add 110kg of IPDI, and add 120kg of H12MDI. Add 280kg of DMF, stir for 20 minutes, raise the temperature to 90°C-95°C for 2h, add 0.4kg of organic bismuth catalyst after 2h, keep warm and continue the reaction for 2.5h, cool down to 60°C by cooling cycle, add 1100kg of cyclohexanone, continue to cool down to 40°C ℃, gradually add 70kg of IPDI dropwise to increase the viscosity to 9000-10000CPS / 25℃, stop the reaction with morphine and stir for 30min, add 750kg of ethyl ester and stir for 30min to unload;

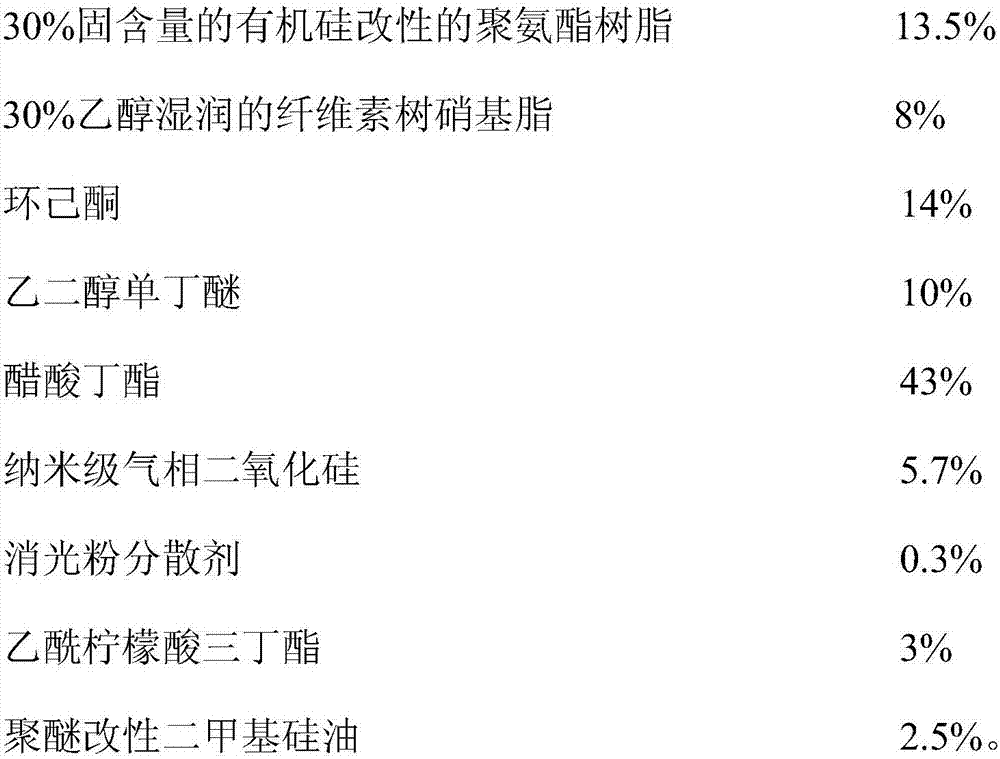

[0027] 2. Treatment agent compounding: add 100kg of organosilicon-modified polyurethane resin with 30% solid content synthesized in the first ste...

Embodiment 3

[0030] A preparation method for synthetic leather with silent wax polishing treatment agent, comprising the steps of:

[0031] 1. Synthesis of silicone-modified polyurethane resin with 30% solid content: put 200kg of reactive silicone with a molecular weight of 2000 into a 3.8-ton reactor, add 250kg of PPG1000, add 140kg of PCL1000, add 100kg of IPDI, and add 140kg of H12MDI. Add 320kg of DMF, stir for 20 minutes, raise the temperature to 90°C-95°C for 2h, add 0.5kg of organic bismuth catalyst after 2h, keep warm and continue the reaction for 2.5h, cool down to 60°C by cooling cycle, add 900kg of cyclohexanone, continue to cool down to 40 ℃, gradually add 90kg IPDI dropwise to increase the viscosity to 9000-10000CPS / 25℃, stop the reaction with morphine and stir for 30min, add 850kg ethyl ester and stir for 30min to unload;

[0032]2, compounding of treatment agent: add the organic silicon modified polyurethane resin 150kg of the 30% solid content synthesized in the first step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com