Fabric planted with silkworm cocoon or silkworm cocoon slice

A silkworm cocoon and fabric technology, applied in the field of fabrics implanted with silkworm cocoons or silkworm cocoon pieces, can solve the problems that have not been effectively developed, and achieve the effects of strong ornamental performance, practicality, convenient production, and low cost pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

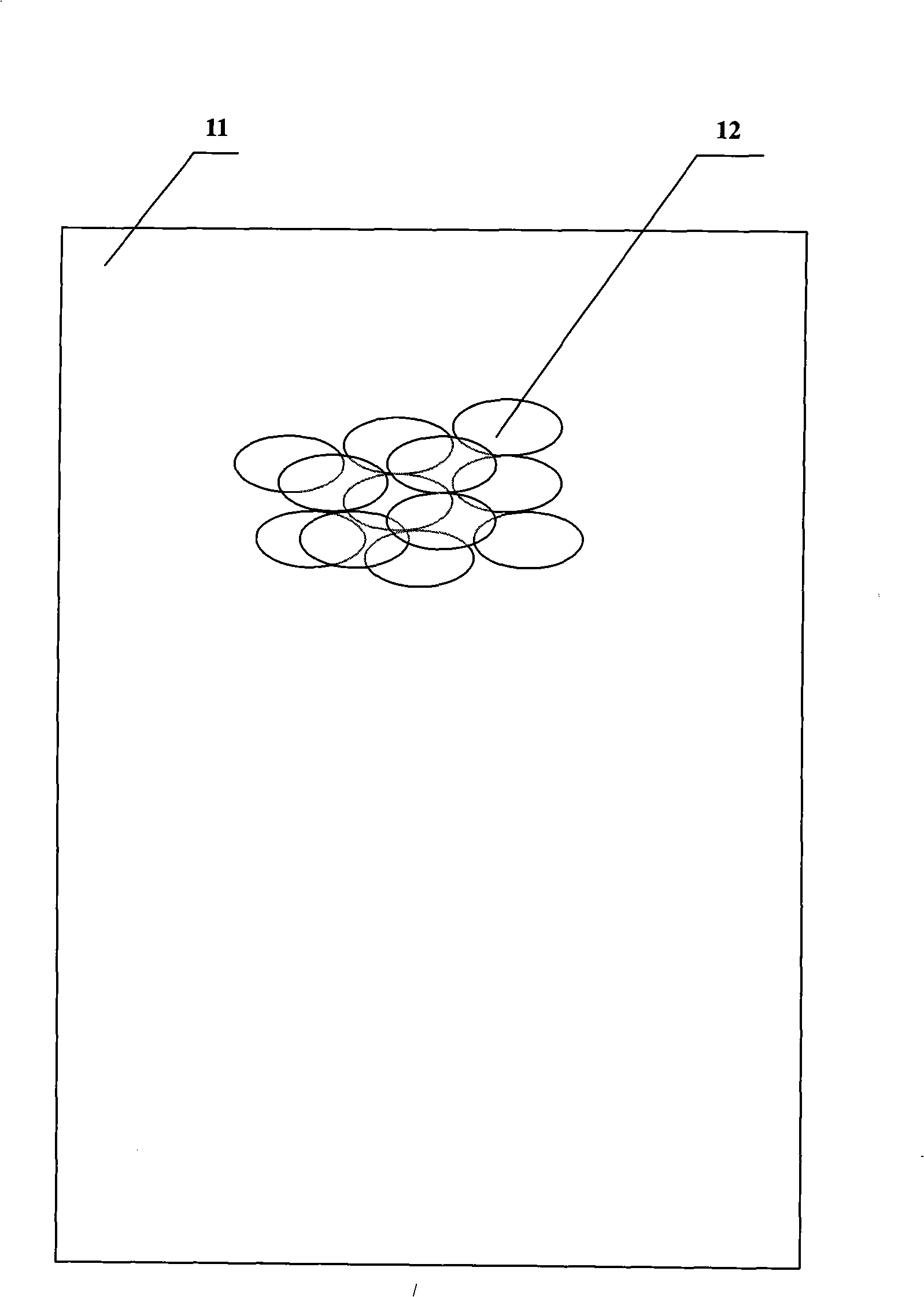

[0016] Such as figure 1 As shown, the original ecology silkworm cocoon 12 is split into two pieces to form half eggshells (it can also be the whole cocoon that takes out the silkworm chrysalis), and each silkworm cocoon 12 is sewn on the bottom fabric in a dot shape, and the silkworm cocoon 12 and the bottom fabric 11 are Close to fixed and three-dimensionally overlapped multiple layers to cover the whole piece of fabric. It is also possible to spray various colors of microcapsule dye drops and auxiliary agents on the above-mentioned processed fabrics, and after steaming or baking at 70-110°C, the microcapsule dyes will be broken to form multi-color fine snowflake granular patterns . The cocoon 12 three-dimensionally overlapped and covered the whole fabric can be processed into the collar of clothing. The visual effect of the clothing decorated with this kind of collar is novel and unique, elegant and graceful, which strengthens the personalization, fashion and innovation of ...

Embodiment 2

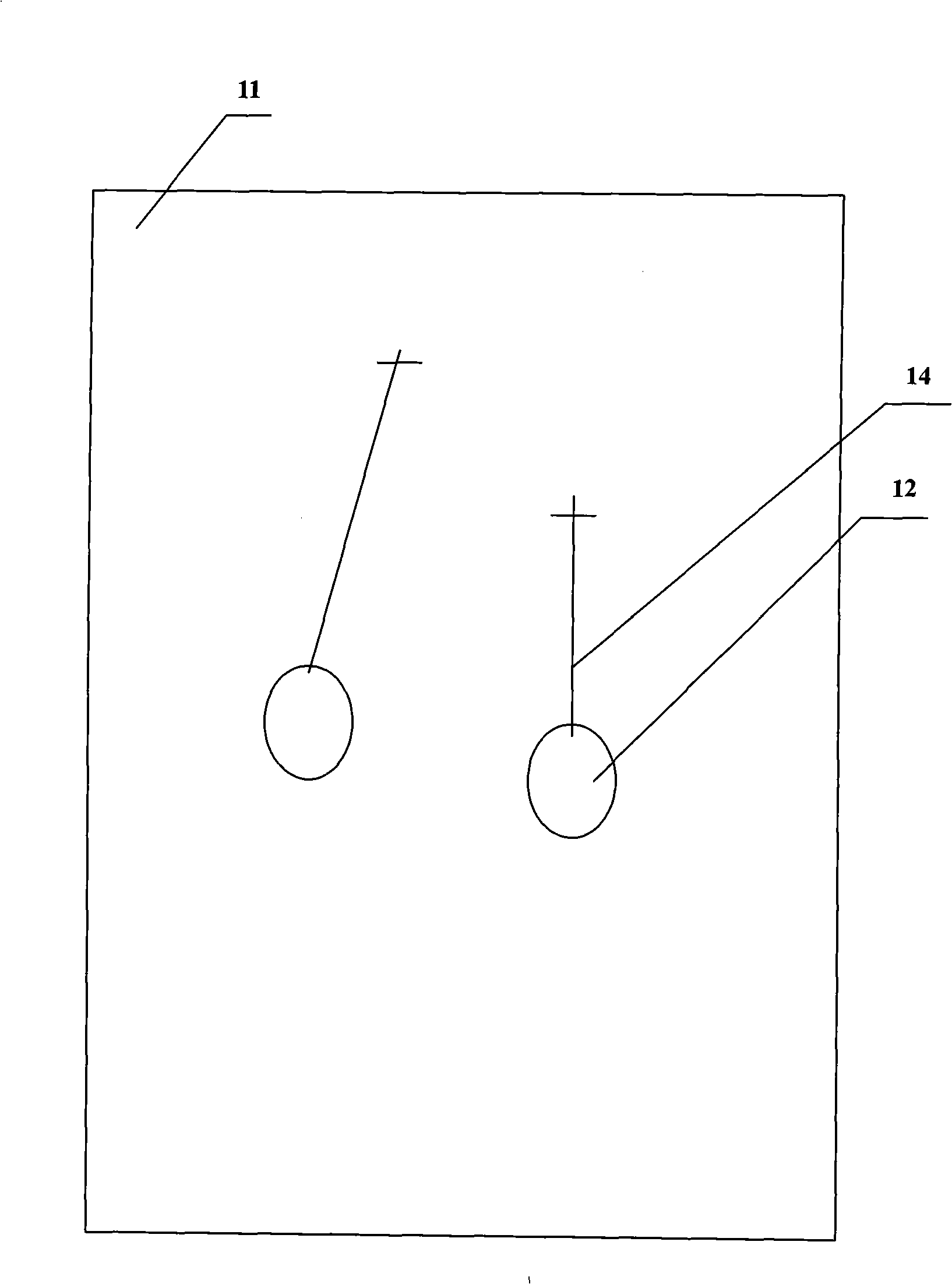

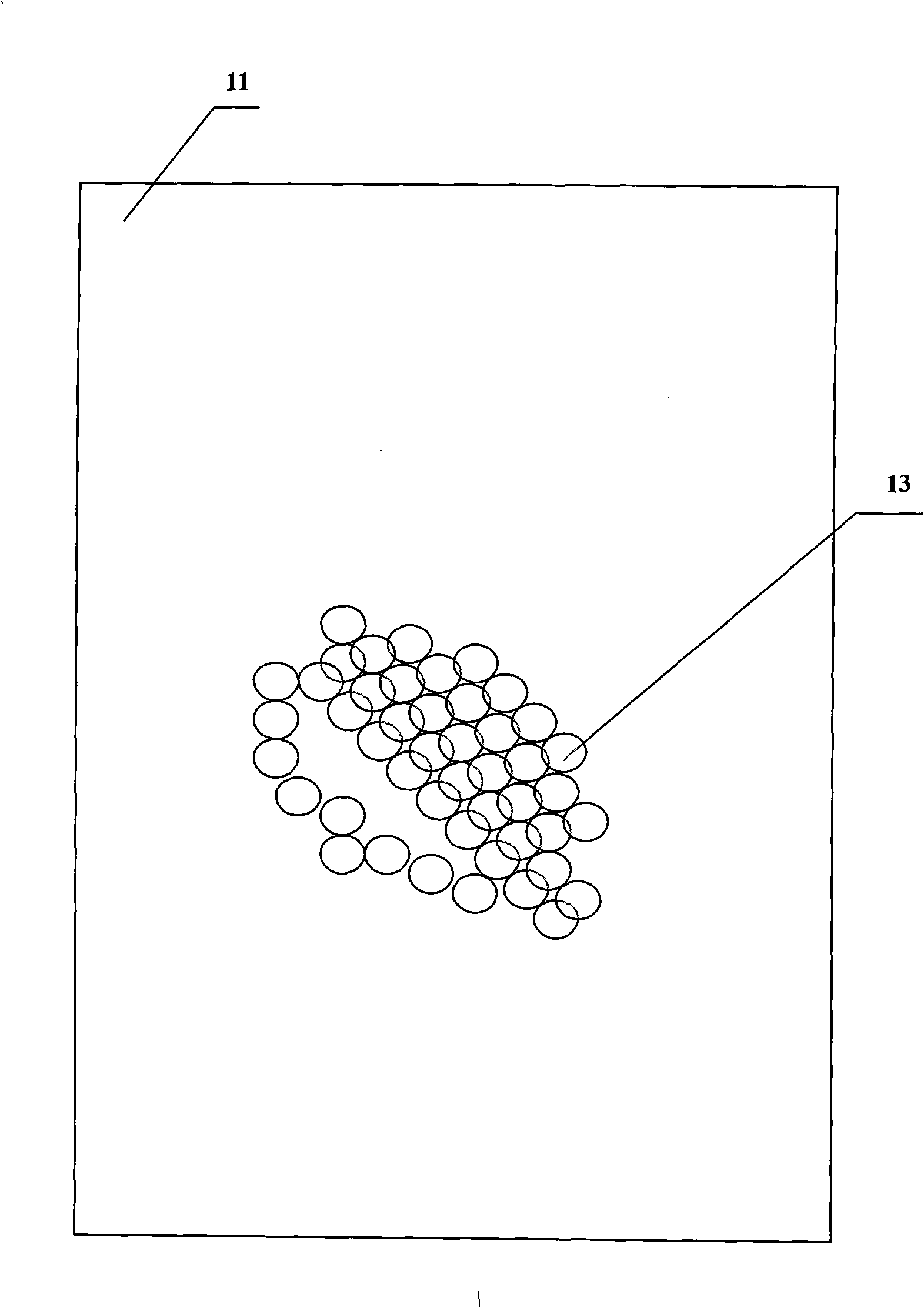

[0018] Such as figure 2 or image 3 Shown, silkworm cocoon 12 is taken out silkworm chrysalis at head cutout, and the color of silkworm cocoon 12 is natural and comprises white and tan, and shape comprises circle, ellipse and kidney shape. Insert one end of a thread 14 and fix it with the silkworm cocoon, then inject an environment-friendly foaming filler mixed with a fragrance microcapsule finishing agent into the silkworm cocoon 12 and seal it, and the other end of the thread 14 is fixed and hung on a formed garment. Any part can hang several pieces. The clothing is steamed or baked at 70-110°C to break the microcapsule finishing agent and release the fragrance for a long time. It is also possible to fix the silkworm cocoon sheet 13 formed into a disc shape on the dress to form various patterns by utilizing the sequin embroidery process. The above two production processes can be used alone or at the same time on a piece of clothing, which not only has a decorative effect...

Embodiment 3

[0020] Such as figure 1 or image 3 As shown, a pattern is pre-treated on a piece of bottom fabric 11 or drawn on paper, and the pre-treatment method can be dyeing, printing, flocking, burnt-out, embroidery or a mixture of two or more of the above methods. Take out the cocoons 12 of the silkworm chrysalis from the incision, inject an environmentally friendly foaming filler mixed with fragrance microcapsules or insecticidal microcapsule finishing agents at the incision and seal it, and the above-mentioned silkworm cocoons 12 are pasted on the fabric pattern with an environmentally friendly adhesive. The position can be pasted to form a three-dimensional raised geometric pattern. The cocoon sheet 13 can also be arranged and pasted in fish scales to form a pattern, or both methods can be used simultaneously. After the above process is completed, the microcapsule finishing agent is broken by steaming or baking at 70-110° C. to release fragrance or insecticide for a long time. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com