Mechanically-pressed carbon-free corundum spinel ladle brick as well as preparation method thereof

A ladle lining brick and spinel technology, applied in the field of refractory materials, can solve the problems of relatively large fluctuation in product performance, inability to eliminate pollution, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

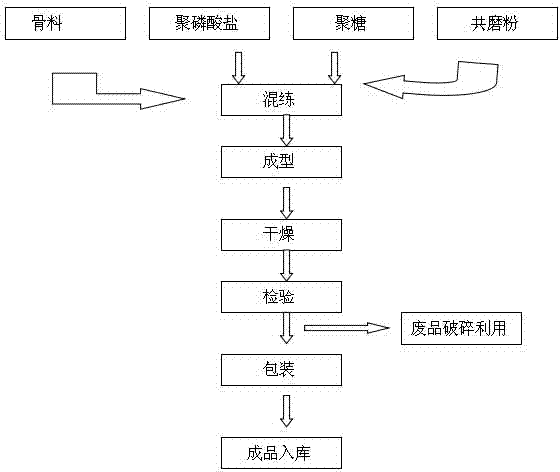

Method used

Image

Examples

Embodiment Construction

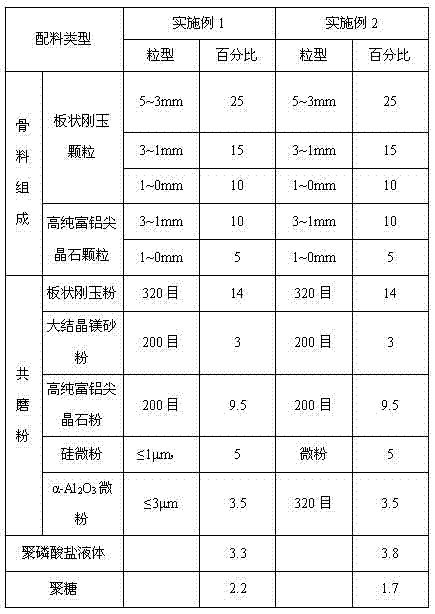

[0009] The machine-pressed carbon-free corundum spinel ladle lining brick of the present invention has the following components by weight percentage: 30-50% of plate-shaped corundum particles, 10-20% of high-purity aluminum-rich spinel particles, and 10% of plate-shaped corundum fine powder. ~20%, large crystalline magnesia fine powder 1~9%, high-purity aluminum-rich spinel fine powder 5~15%, high-purity silicon micropowder 1~10%, imported multi-peak α-Al 2 o 3 Micropowder 2-10%, metal silicon 1-4%, binder: polyphosphate 1-5%, polysaccharide 1-3%.

[0010] Among them, there are three particle sizes of tabular corundum particles: 5-3mm, 3-1mm, and 1-0mm; the particle sizes of tabular corundum fine powder are 320 mesh and 200 mesh, and the mass percentages of its chemical components are: Al 2 o 3 ≥99.0%, SiO 2 ≤0.15%, Fe 2 o 3 ≤0.05%, Na 2 O+K 2 O≤0.5%.

[0011] The particle size of high-purity aluminum-rich spinel particles is 1-0.5mm, 0.5-0mm, the particle size of high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com