Charge method of lead-acid storage battery

A lead-acid battery and charging method technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of excessive gas discharge, battery scrap, battery life impact, etc., so as to shorten the charging time and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings.

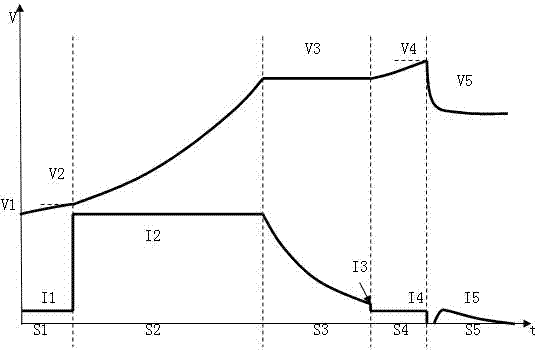

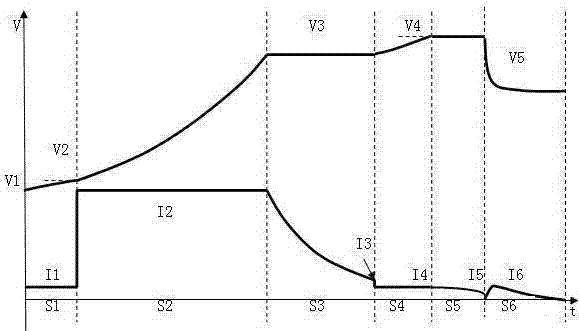

[0019] Such as figure 2 Shown is the curve schematic diagram of the whole charging process of a lead-acid battery of the present invention, the whole charging process is divided into six stages: the first stage is the pre-charging stage, when the battery is connected to the charger, the voltage of the battery is detected by the charger At this time, the voltage is V1, and the constant current pre-charging is carried out with the first preset current I1 (0.02-0.025C). The voltage of the battery or battery pack gradually rises from V1 to V2, and enters the next stage of charging when the charging time reaches S1 , and S1 is less than 4 hours.

[0020] The second stage is the constant current charging stage, with the second preset current I2 (0.15-0.25C) for constant current charging, the voltage gradually rises from V2 to V3, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com