Industrial hazardous waste incineration system

A hazardous waste and industrial technology, applied in the field of waste incineration system, can solve problems such as insufficient use, infection, and low work efficiency, and achieve the effects of convenient repair and maintenance, increased contact area, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

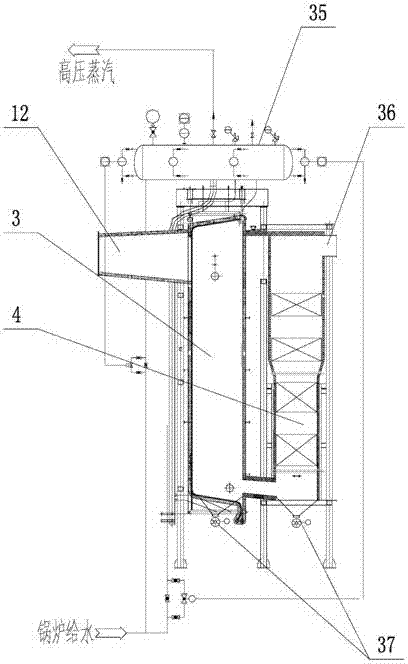

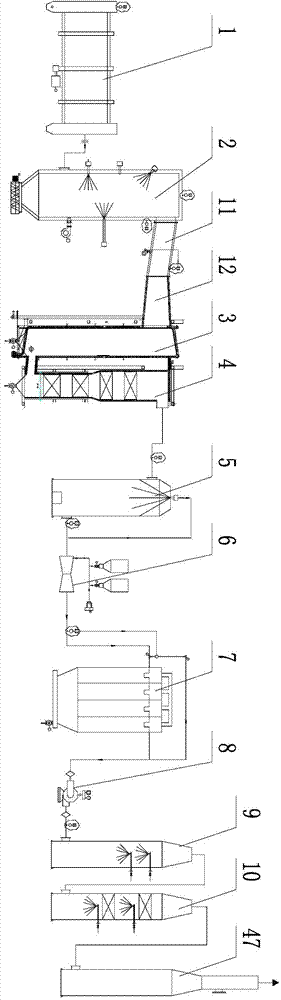

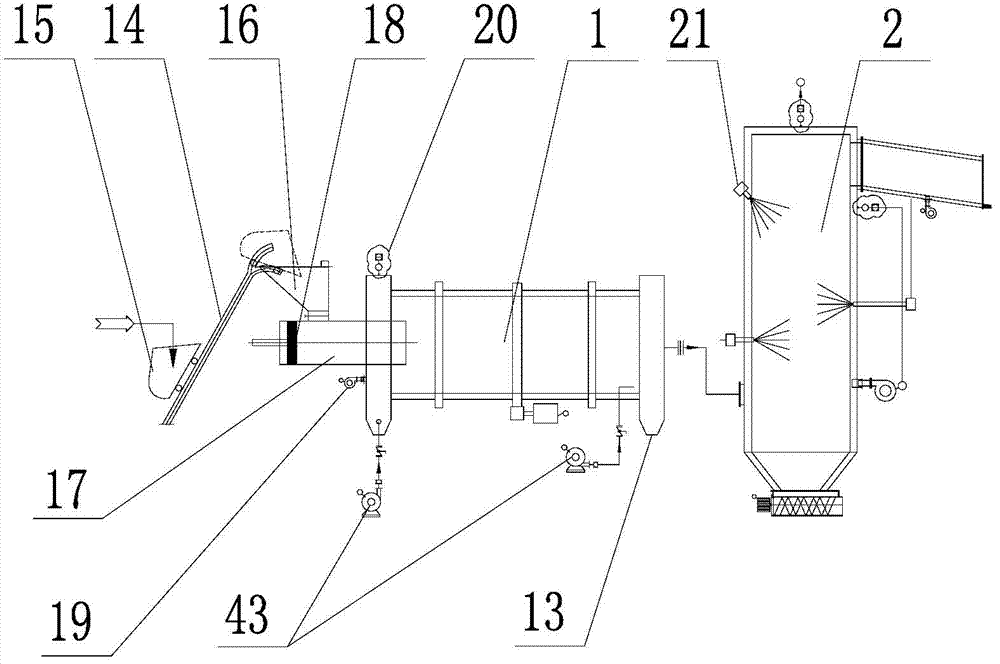

[0032] This embodiment provides an industrial hazardous waste incineration system, including a rotary kiln 1, a waste liquid furnace 2, a membrane wall type settling furnace 3, a membrane wall type waste heat boiler 4, a semi-dry quench tower 5, a dry reactor 6, and a bag dust collector device 7, induced draft fan 8, spray tower 9, absorption tower 10, natural gas pipeline 24, low-pressure steam pipeline 25, compressed air pipeline 45 and chimney 47, there is also between waste liquid furnace 2 and membrane wall type settling furnace 3 There is a secondary combustion chamber 11 and a pre-cooling chamber 12;

[0033] One end of the rotary kiln 1 is equipped with a feeding device, and the other end is connected with the waste liquid furnace 2 through a flue pipe. The end of the rotary kiln 1 close to the waste liquid furnace 2 is also provided with an ash outlet 13. The feeding device includes a lifting feeding device and a hydraulic sealing The feeding device consists of a lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com