Method for drying terephthalic acid under micro-negative pressure

A technology of terephthalic acid and micro-negative pressure, which is applied in the drying field of terephthalic acid, can solve the problems of poor environment in the working area, shortened service life, and impact on production capacity, so as to reduce the probability of entering the gap of sealing components , reduce production costs and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

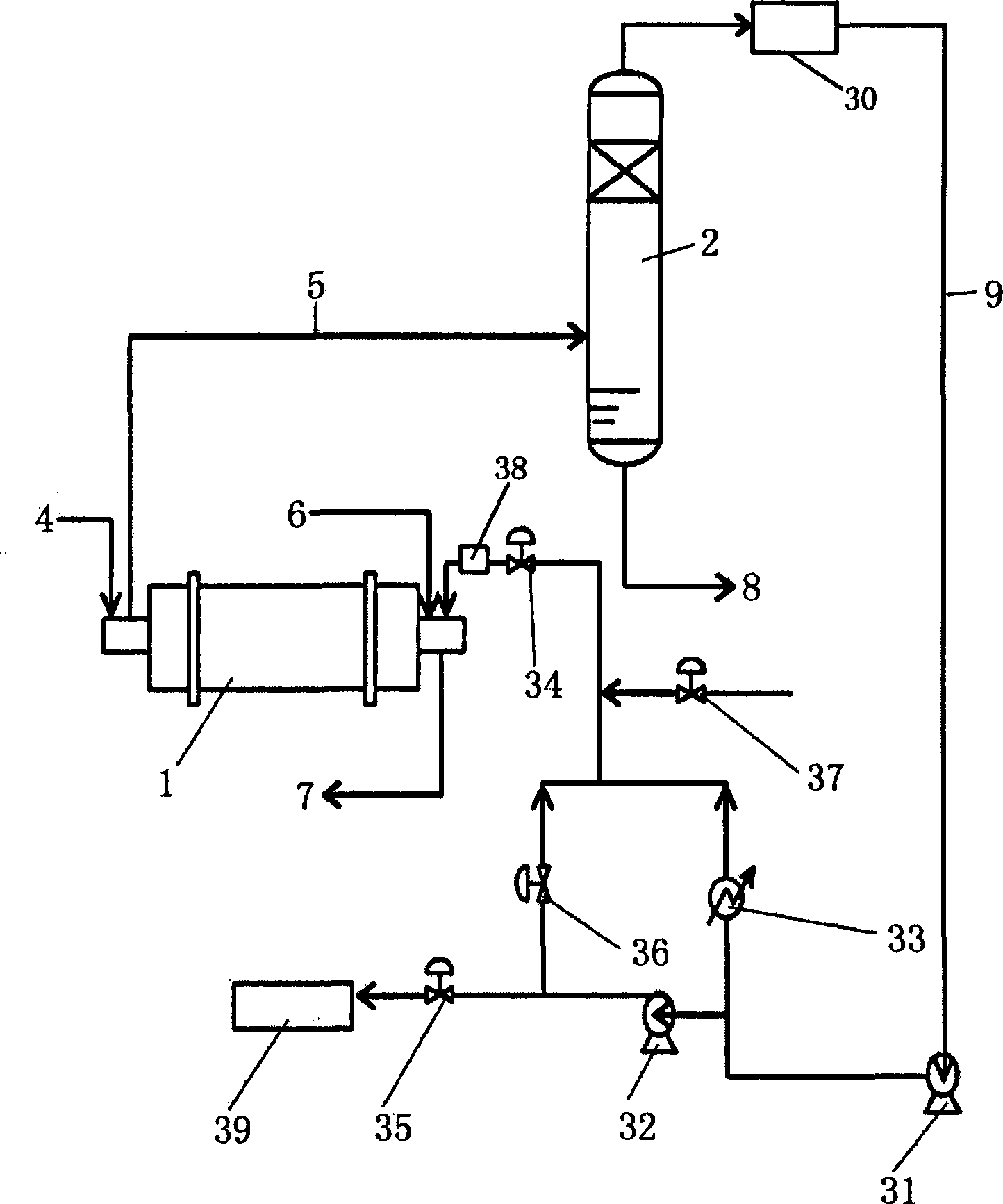

[0023] Example 1 as figure 1 As shown, in the dryer 1, the 4.0-8.0kg / cm 2 g low-pressure steam 6 heats the terephthalic acid wet material with a moisture content of 10wt% to 14wt% from 4 to 120°C, and the evaporated acetic acid and water vapor are heated to 80°C to 130°C by the heat exchanger 33 traveling in reverse °C N 2 The air flow 5 takes it away, and the low-pressure steam condensate 7 enters the steam recovery system.

[0024] After the saturated gas stream 5 enters the washing tower 2, a small amount of terephthalic acid powder entrained is washed in the washing tower 2; the saturated N 2 Airflow 5 is cooled to 30°C to 50°C, most of the acetic acid and most of the water vapor carried in the airflow 5 are condensed, and the stream 8 composed of condensed acetic acid, water vapor and supplemented fresh acetic acid enters the feed preparation unit.

[0025] Washed and cooled N carrying a small amount of acetic acid and water vapor stream 2 The gas flow 5 is reheated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com