Corrosion-resistant and scale-inhibiting cleaning agent for medium-high pressure boiler and preparation method of corrosion-resistant and scale-inhibiting cleaning agent

A medium-high pressure, cleaning agent technology, applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve the problem of no cleaning and dissolution effect of scaling, no steam pipeline corrosion and deposition control, Heat wastage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

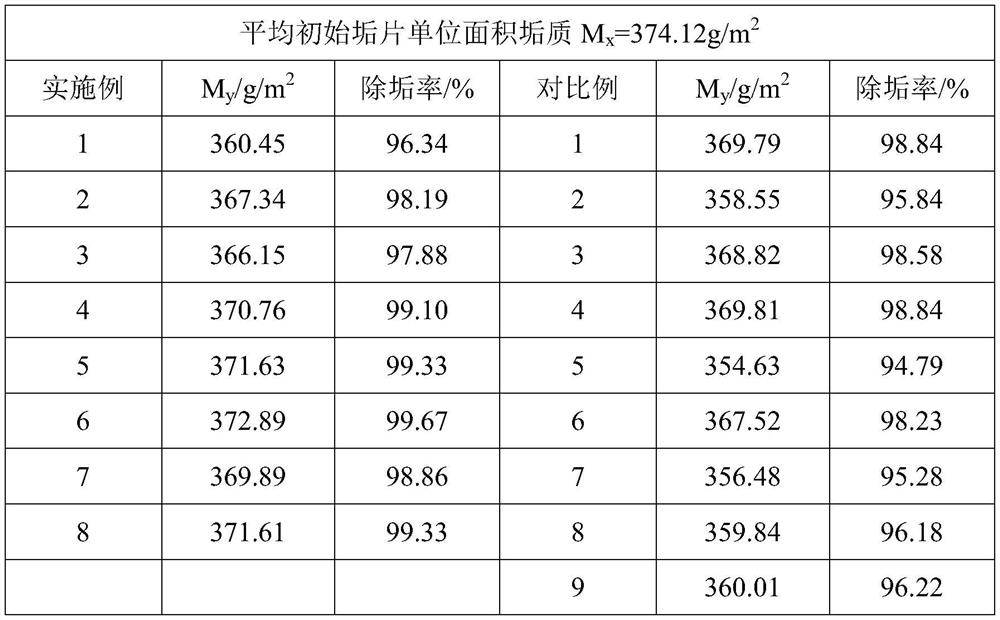

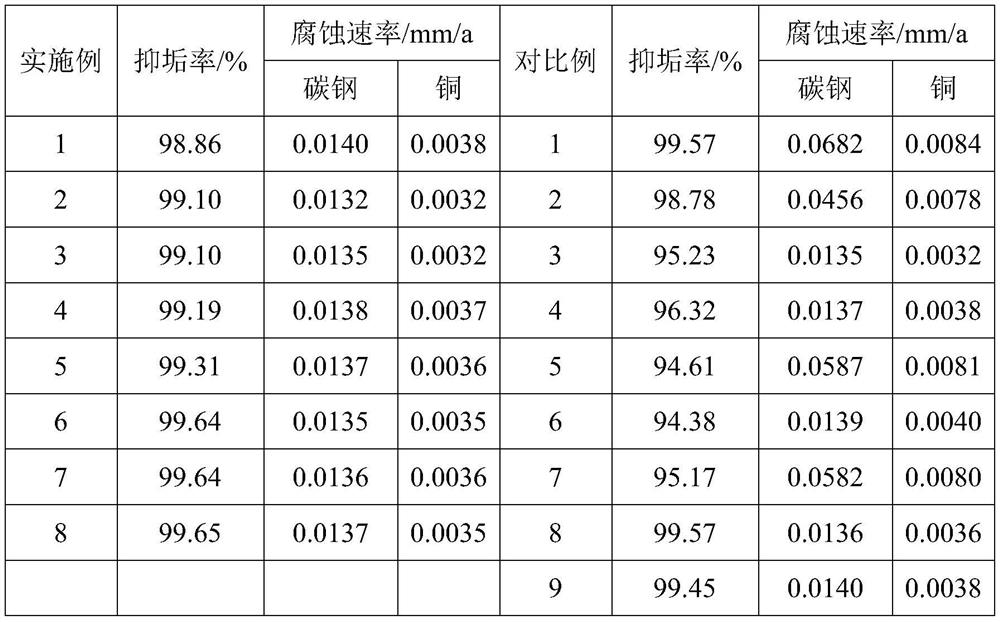

Examples

Embodiment 1

[0029] A medium and high pressure boiler anti-corrosion and scale-inhibiting cleaning agent, the preparation method comprising the following steps:

[0030] Step S1: Put 1% polyaspartic acid into a clean and dry reactor, add deionized water and heat up to 50-60°C to dissolve, and keep the temperature of the reactor;

[0031] Step S2: Add 0.5% polyol phosphate into the reactor, then add 1% sodium humate dropwise into the reactor, stir and keep warm for 1-2 hours;

[0032] Step S3: Dissolve tallow amine and triethylenediamine in a small amount of deionized water at room temperature at a mass ratio of 1:1 to make an organic corrosion inhibitor base liquid, and then add 5% diethylhydroxylamine and 5% organic corrosion inhibitor base solution, stir and heat up to 70-80°C, keep warm for 2-3 hours;

[0033] Step S4: Add 0.5% polyoxyethylene polyoxypropylene glyceryl ether into the reaction kettle, pressurize after stirring, release the pressure after 1-2 hours and cool naturally to ...

Embodiment 2

[0035] A medium and high pressure boiler anti-corrosion and scale-inhibiting cleaning agent, the preparation method comprising the following steps:

[0036] Step S1: Put 1% polyaspartic acid into a clean and dry reactor, add deionized water and heat up to 50-60°C to dissolve, and keep the temperature of the reactor;

[0037] Step S2: Add 0.1% polyol phosphate into the reactor, then add 1% sodium humate dropwise into the reactor, stir and keep warm for 1-2 hours;

[0038] Step S3: Dissolve tallow amine and triethylenediamine in a small amount of deionized water at room temperature at a mass ratio of 1:1 to make an organic corrosion inhibitor base liquid, and then add 10% diethylhydroxylamine and 12% organic corrosion inhibitor base solution, stir and heat up to 70-80°C, keep warm for 2-3 hours;

[0039] Step S4: Add 0.5% polyoxyethylene polyoxypropylene glyceryl ether into the reaction kettle, pressurize after stirring, release the pressure after 1-2 hours and cool naturally t...

Embodiment 3

[0041] A medium and high pressure boiler anti-corrosion and scale-inhibiting cleaning agent, the preparation method comprising the following steps:

[0042] Step S1: Put 1% polyaspartic acid into a clean and dry reactor, add deionized water and heat up to 50-60°C to dissolve, and keep the temperature of the reactor;

[0043] Step S2: Add 0.1% polyol phosphate into the reactor, then add 1% sodium humate dropwise into the reactor, stir and keep warm for 1-2 hours;

[0044] Step S3: Dissolve tallow amine and triethylenediamine in a small amount of deionized water at room temperature at a mass ratio of 1:1 to make an organic corrosion inhibitor base liquid, and then add 15% diethylhydroxylamine and 18% organic corrosion inhibitor base solution, stir and heat up to 70-80°C, keep warm for 2-3 hours;

[0045] Step S4: Add 0.5% polyoxyethylene polyoxypropylene glyceryl ether into the reaction kettle, pressurize after stirring, release the pressure after 1-2 hours and cool naturally t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com