Outside external burner

A combustion device and the main shell technology, which is applied in the field of outdoor installation type combustion devices, can solve the problem that the combustion deterioration cannot be completely eliminated, and achieve the effect of maintaining combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

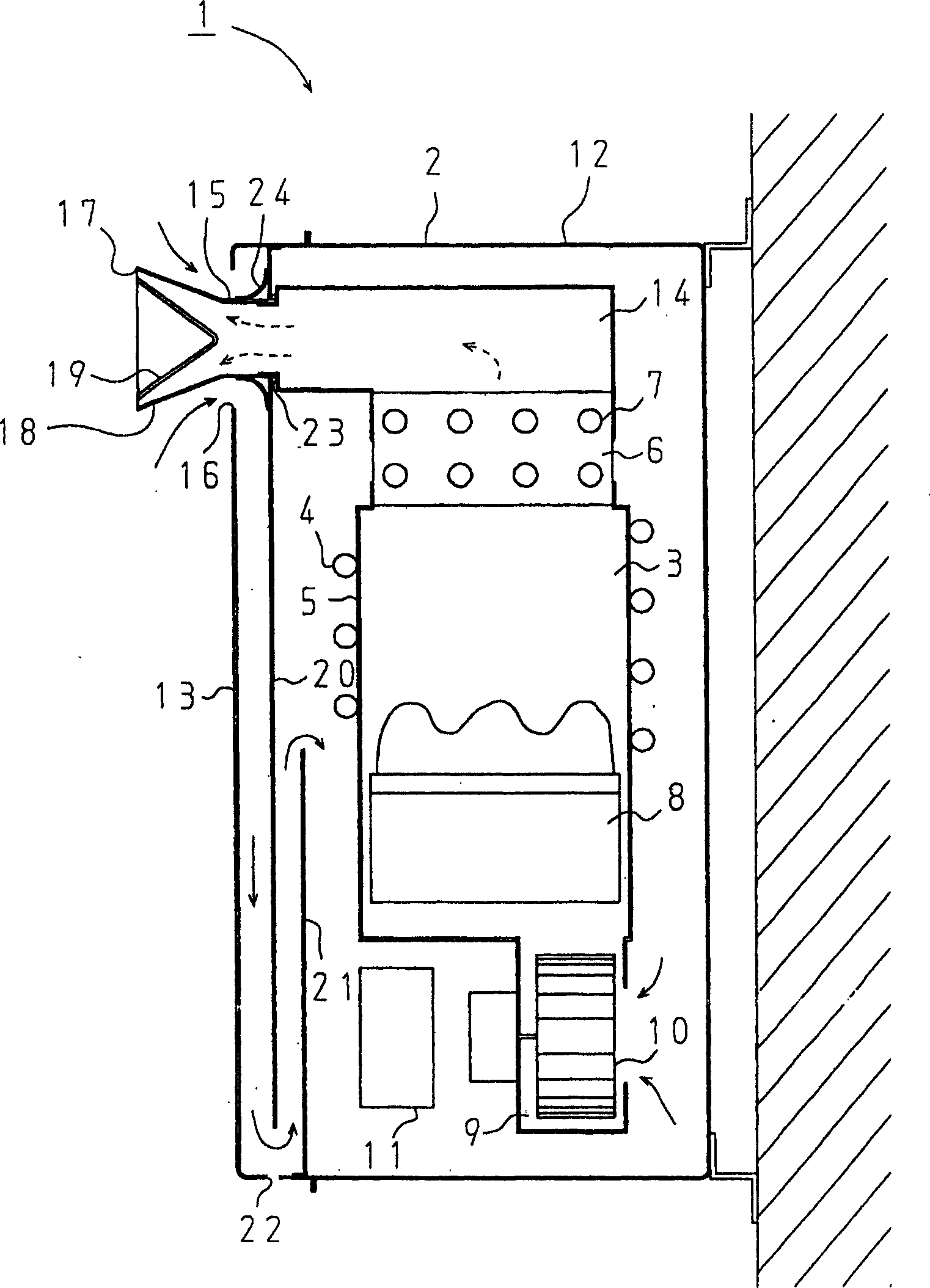

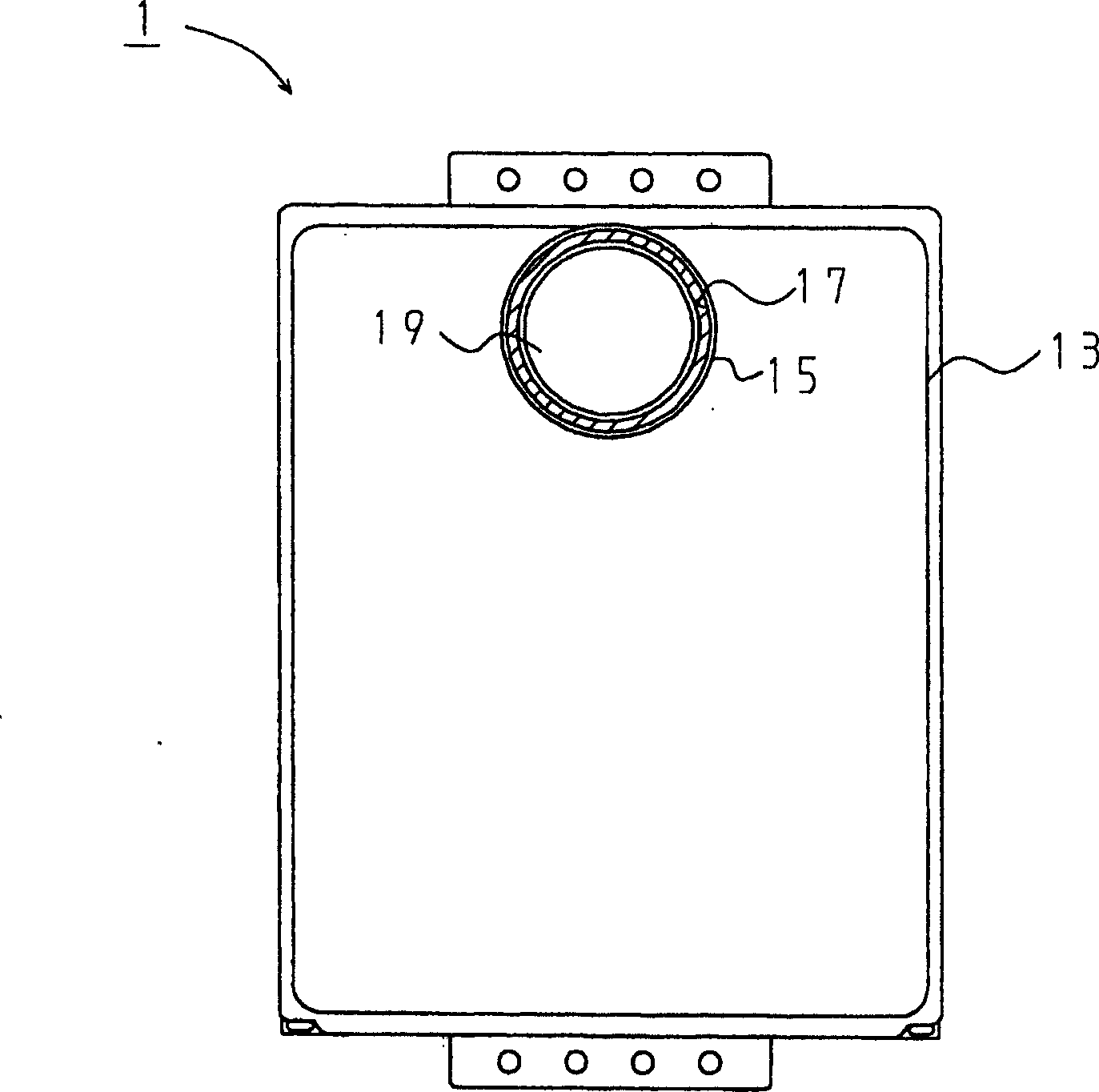

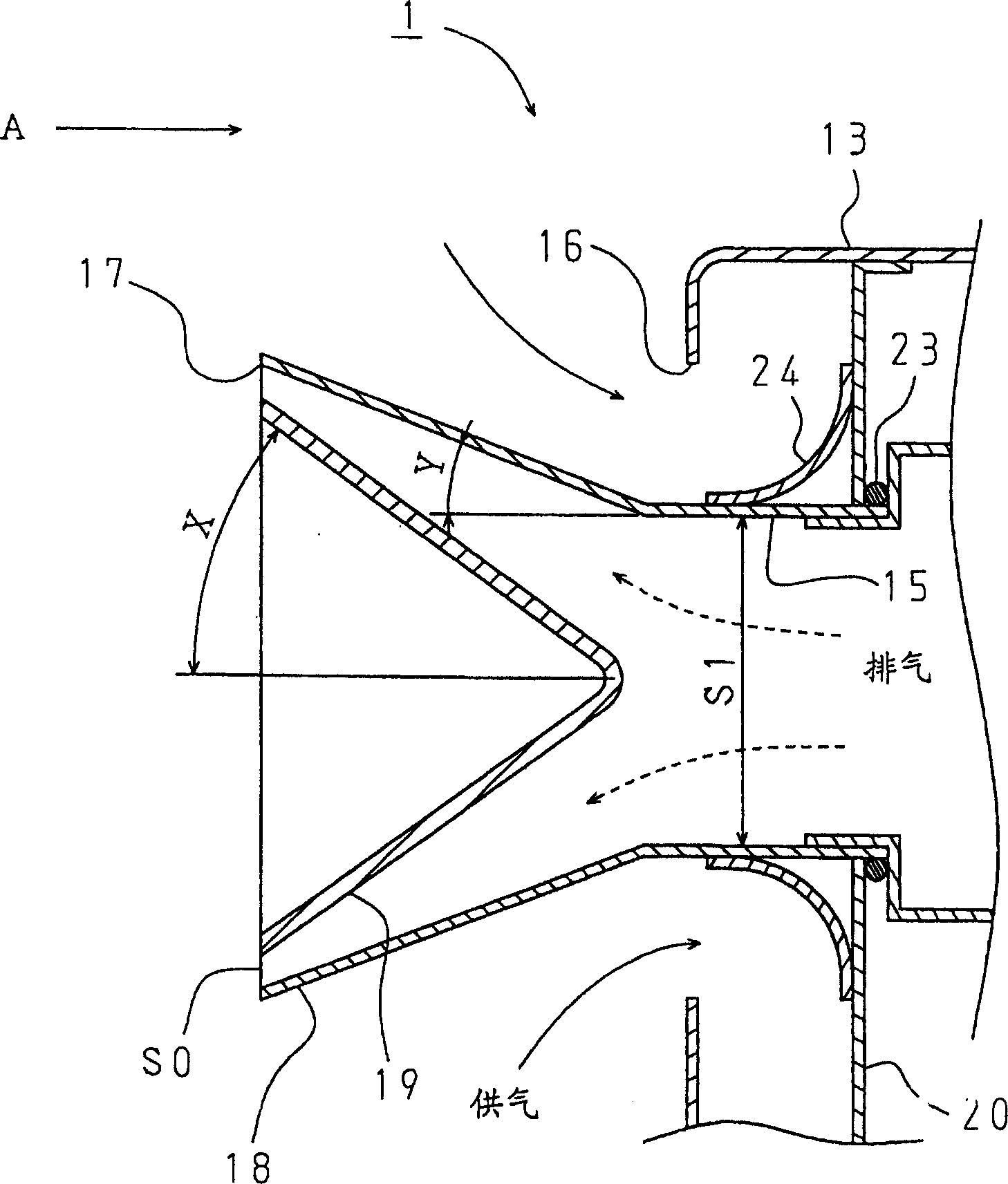

[0038] like figure 1 , figure 2 As shown, the outdoor water heater 1 as Embodiment 1 of the present invention is set up like this: an inner body 5 is arranged inside the casing 2 (equivalent to the appliance main body casing of the present invention), and a combustion chamber is formed inside the inner body 5. 3. A spiral water supply pipe 4 is wound on the outer peripheral surface of the combustion chamber 3 . The water supply pipe 4 is connected to the heat absorption pipe 7 of the heat exchanger 6 arranged on the upper part of the inner body 5, and the heat exchanger 6 is heated by the burner 8 arranged under the inner body 5 to convectively overheat The water in the heat absorption pipe 7 of the exchanger 6 is heated so that hot water can flow out from a hot water outlet pipe (not shown) connected to the outlet side of the heat absorption pipe 7 . An air supply chamber 9 is formed at a lower portion of the combustion chamber 3 , and a fan 10 is provided in the air suppl...

Embodiment 2

[0055] Below, combine Figure 5 The water heater 201 of Example 2 is demonstrated. In addition, parts that are different from those in Embodiment 1 will be described, and the same reference numerals will be assigned to overlapping parts, and descriptions thereof will be omitted.

[0056] In the water heater 201 of the second embodiment, the angle X' of the conical surface at the front end of the backwind prevention plate 219 is reduced to the same angle as the inclination angle Y of the front end side of the exhaust tube 15 to form an exhaust air flow. The straightening portion 227 has a constant width of the passage (the distance between the exhaust pipe 15 and the backwind preventing plate 219 ). In the rectification part 227, the width of the exhaust passage is fixed, and the air flow of the exhaust gas is rectified from turbulent flow to laminar flow, so that the exhaust gas discharge can be diffused further.

[0057] In addition, when the length L of the rectification p...

Embodiment 3

[0059] Below, combine Image 6 , Figure 7 The water heater 301 of Example 3 is demonstrated. Figure 7 Yes Image 6 A view from direction A. In addition, parts that are different from those in Embodiment 1 will be described, and the same reference numerals will be assigned to overlapping parts, and descriptions thereof will be omitted.

[0060] In the water heater 301 of the third embodiment, the angle X of the conical surface of the backwind prevention plate 319 and the inclination angle Y of the tip of the exhaust tube 15 are made to be the same angle. And, between the front end expansion pipe portion 18 of the exhaust tube 15 and the backwind prevention plate 319, a guide barrier 328 is provided. The guide barrier 328 is formed into a ring shape with a flat plate having a substantially V-shaped cross section, and the guide barrier 328 The expanded portion of the stopper 328 is provided facing outward. The guide partition 328 divides the exhaust passage into two annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com