Snow making tower and method of making snow

a technology of snow making tower and sprinkling, which is applied in the field of fluid sprinkling, can solve the problems of inability to weld aluminum pipe sections of increasing diameter end-to-end telescopic fashion, the forty foot section of sufficient diameter aluminum pipe is simply too heavy for suspension at this extreme height above ground, and the practicability of aluminum pipe manufacturing, etc., to achieve better interaction and atomization, better contact, and tighter plume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

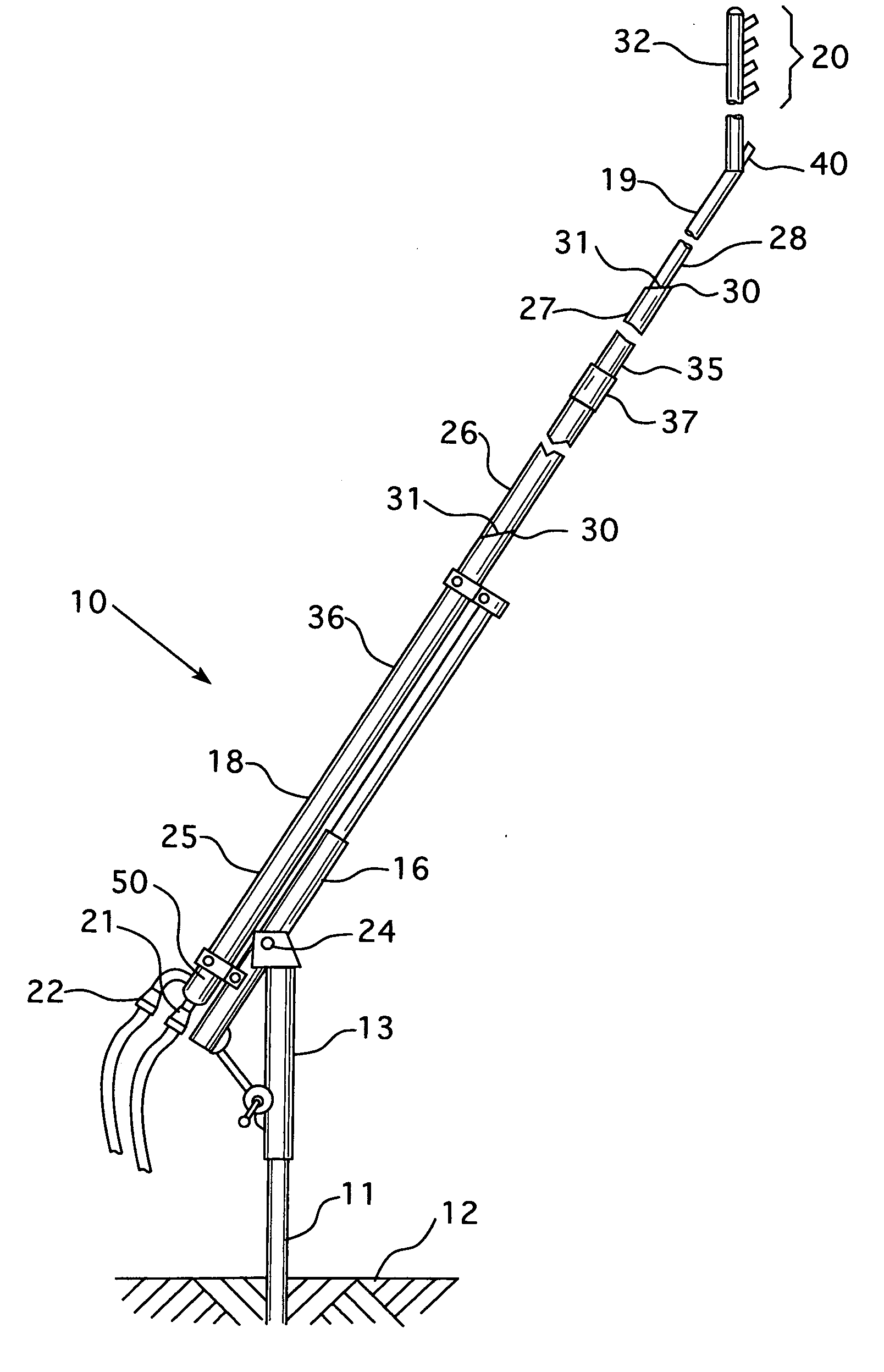

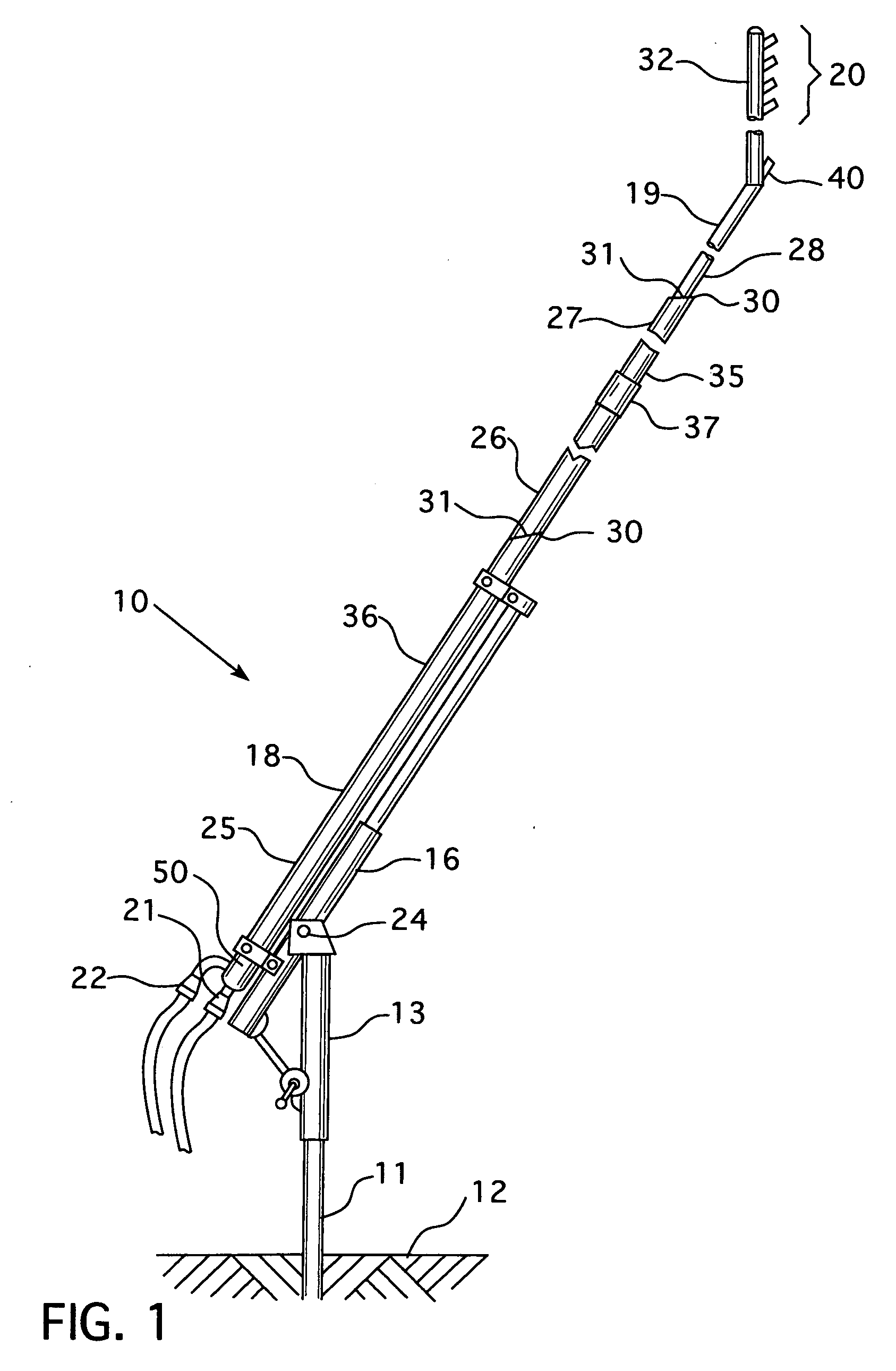

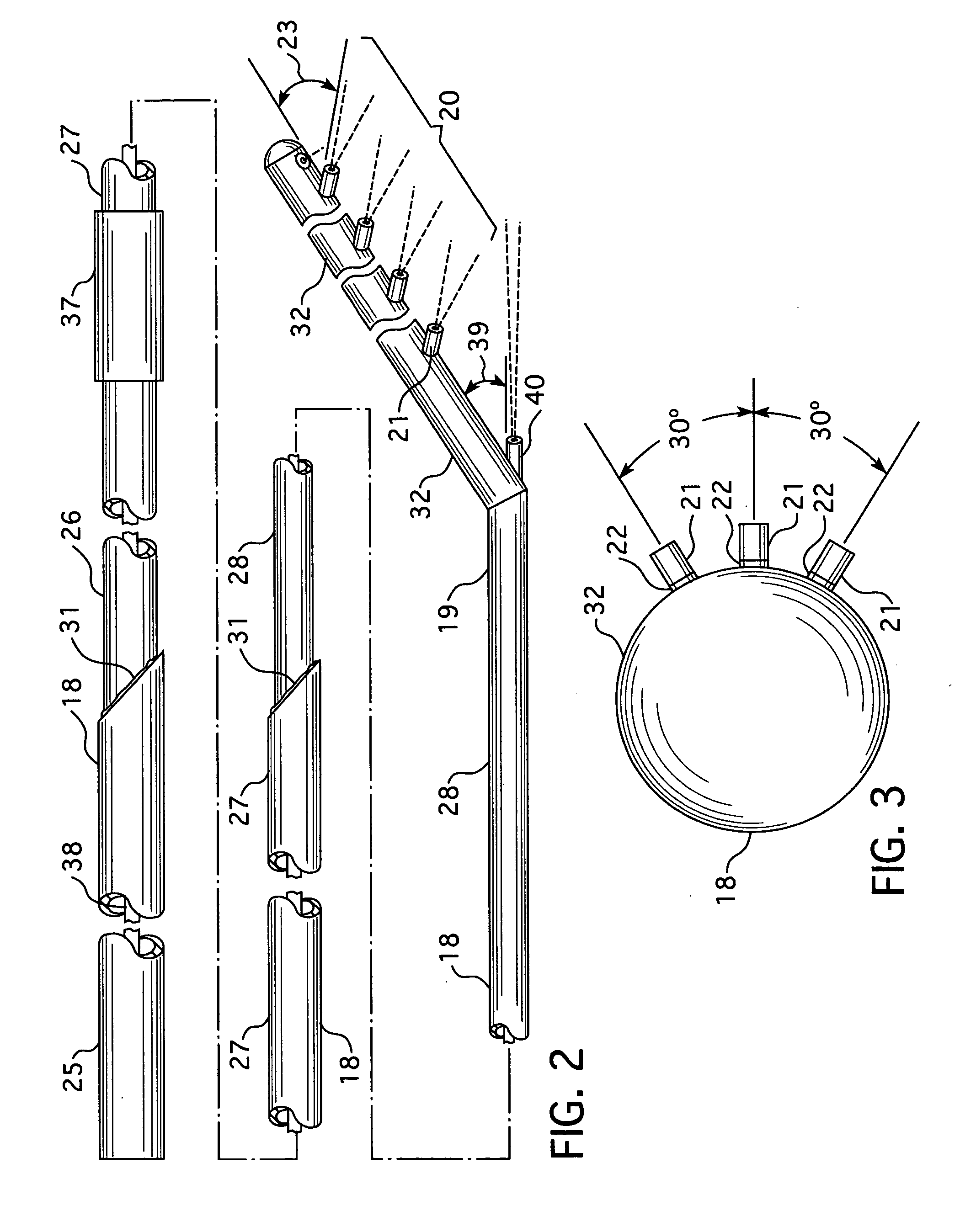

[0019]Referring to the drawings, the snow making tower 10 of the present invention includes a substantially vertical ground support pole 11 having the bottom end thereof anchored into the ground surface 12. Tower support sleeve 13 is coaxially mounted on ground support pole 11 for support thereon and free axial rotation thereon for a full 360 degrees.

[0020]Upwardly extending support arm 16 is pivotally supported intermediate its ends to the upper end of tower support sleeve 13 at pivotal connection 24 for pivotal movement substantially from horizontal to vertical. Elongated snow making tower pipe 18 is provided with snow making nozzles 20 adjacent the upper end of the tower at upper portion 19 and respective water and air connections 22 and 21 are provided at the lower end of tower pipe 18 for connection to remote sources of air and water under pressure through the hoses depicted for supply to the nozzles 20 for ultimate discharge into ambient atmosphere for manufacture of snow in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com