Patents

Literature

35results about How to "Prevent nitriding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

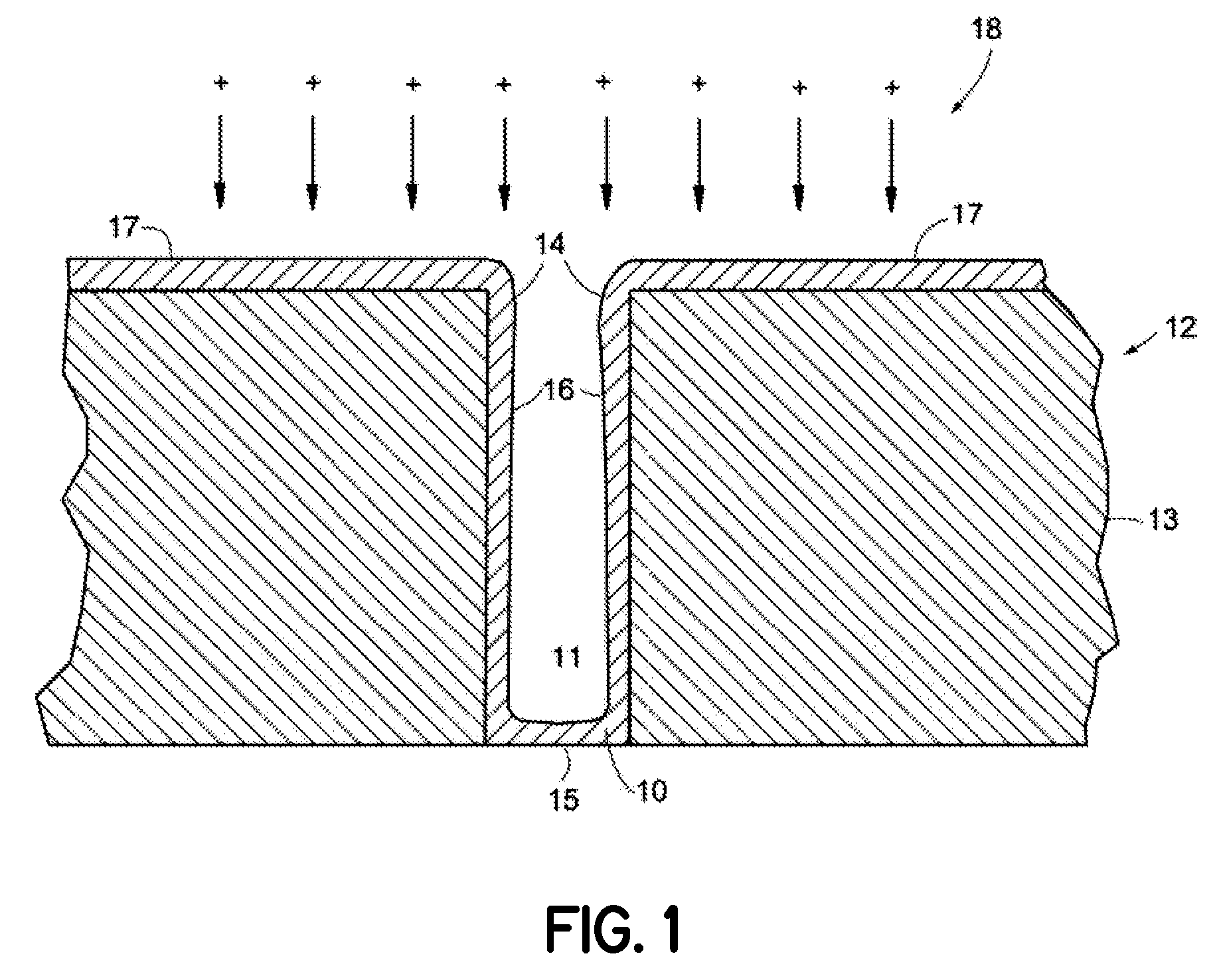

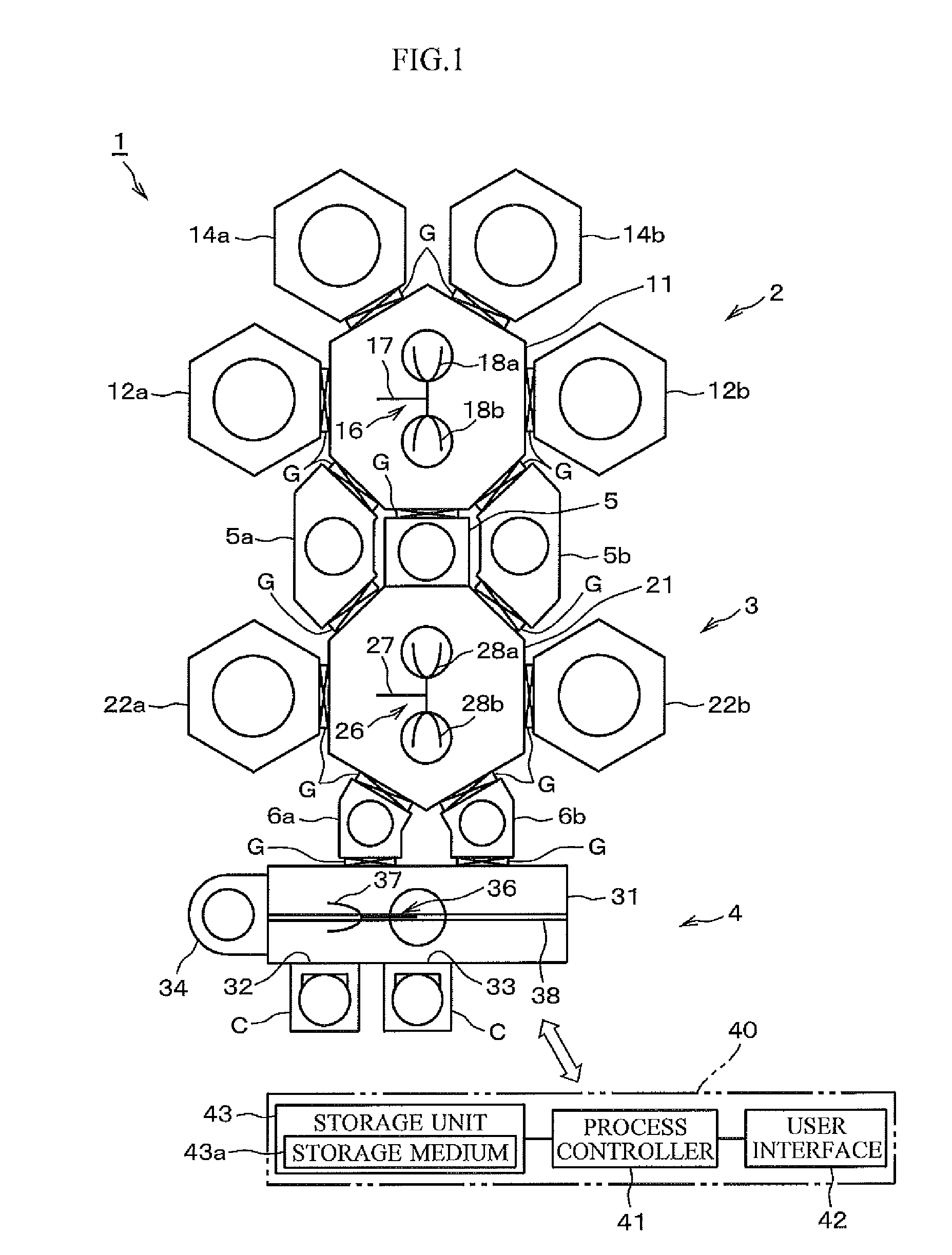

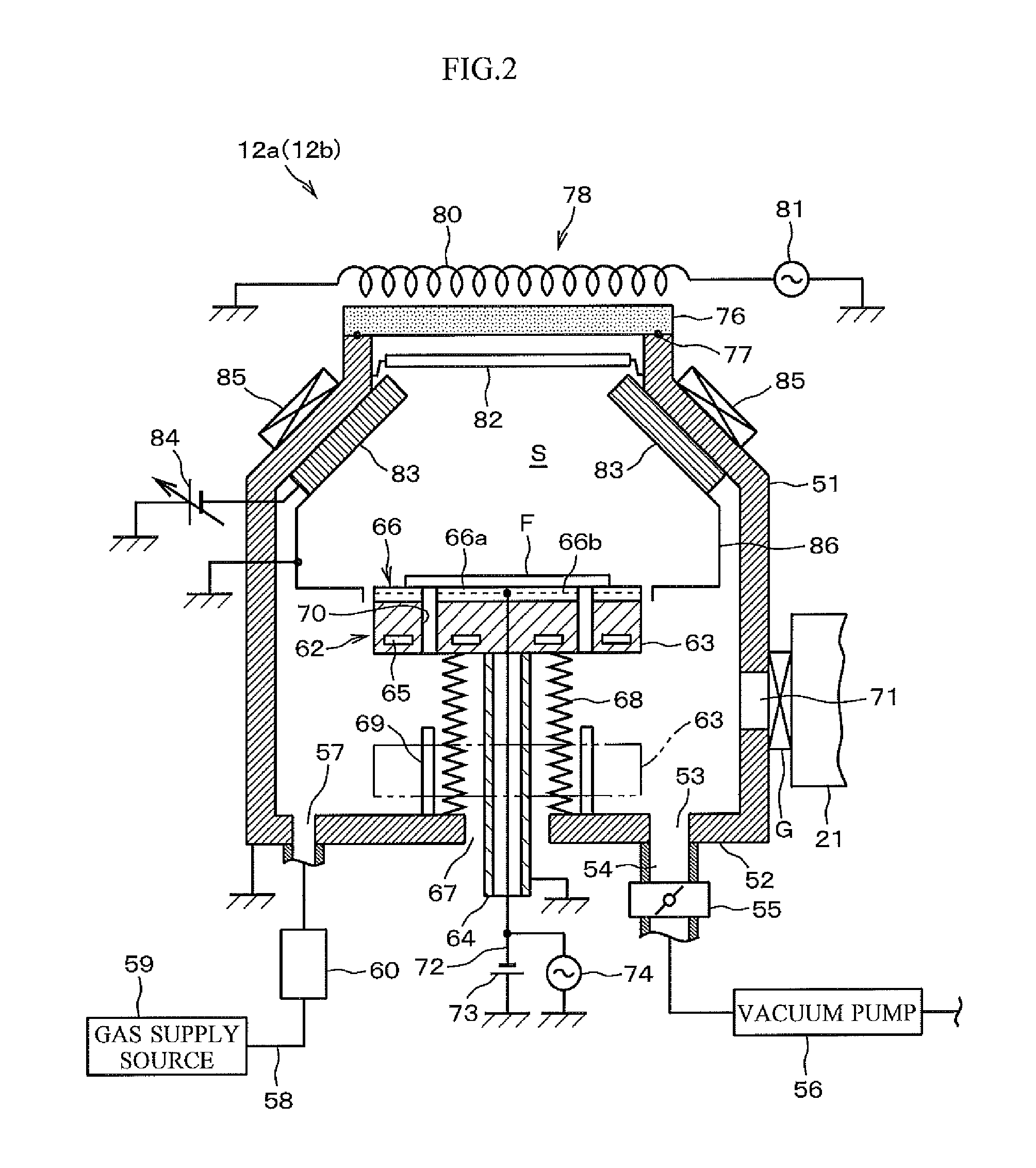

BARRIER DEPOSITION USING IONIZED PHYSICAL VAPOR DEPOSITION (iPVD)

InactiveUS20070238279A1Prevent nitridingElectric discharge tubesVacuum evaporation coatingNano sizeHigh resistivity

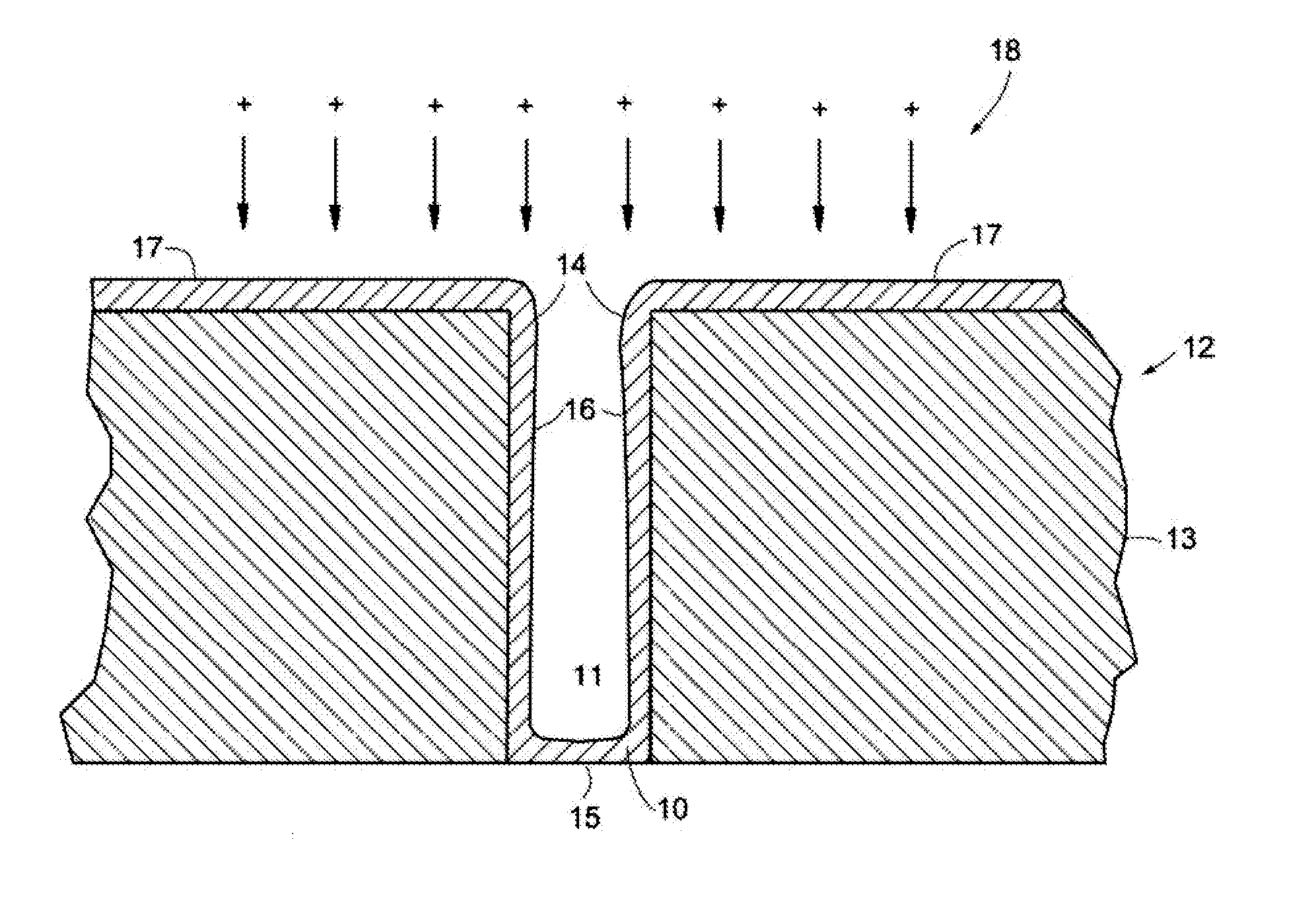

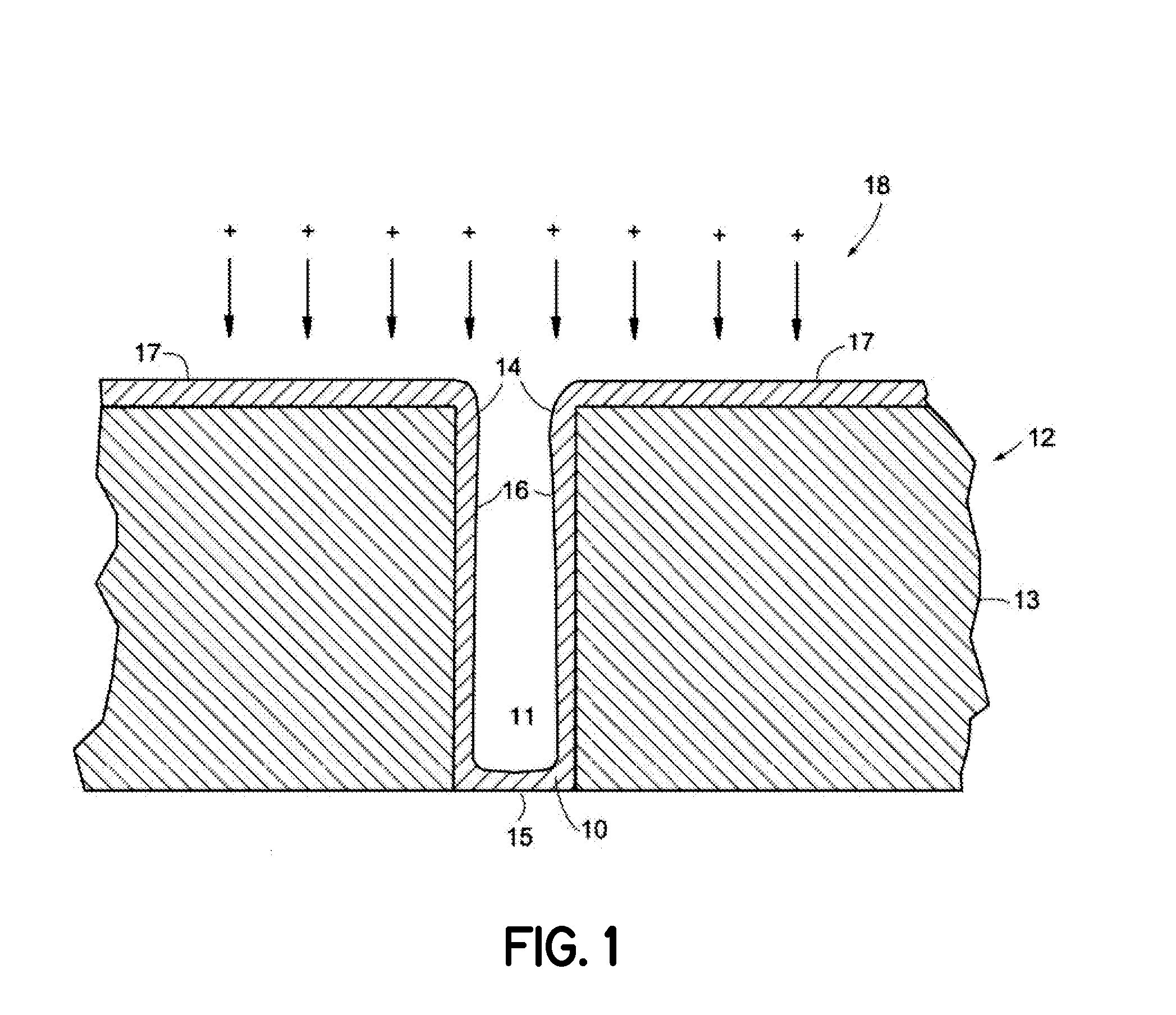

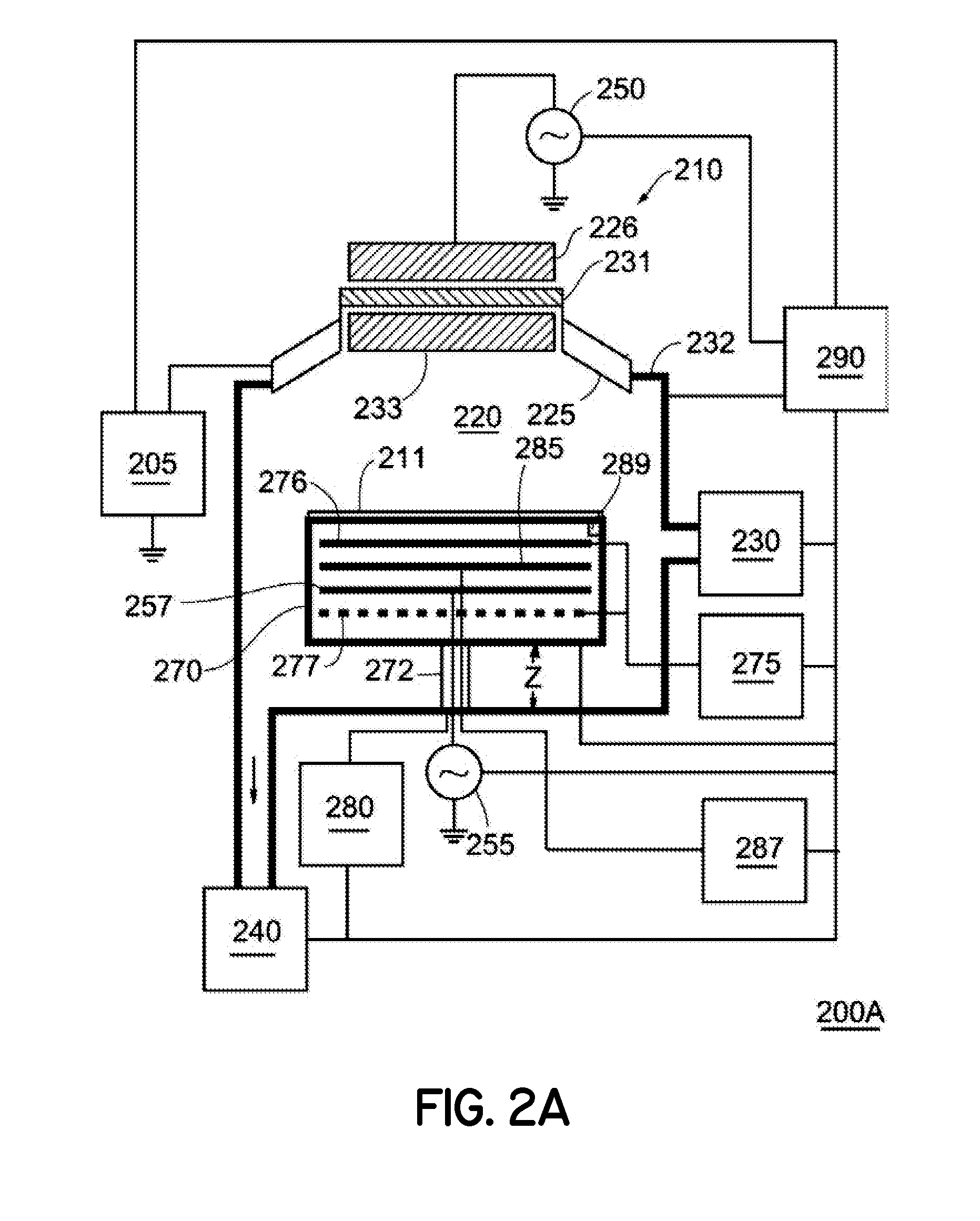

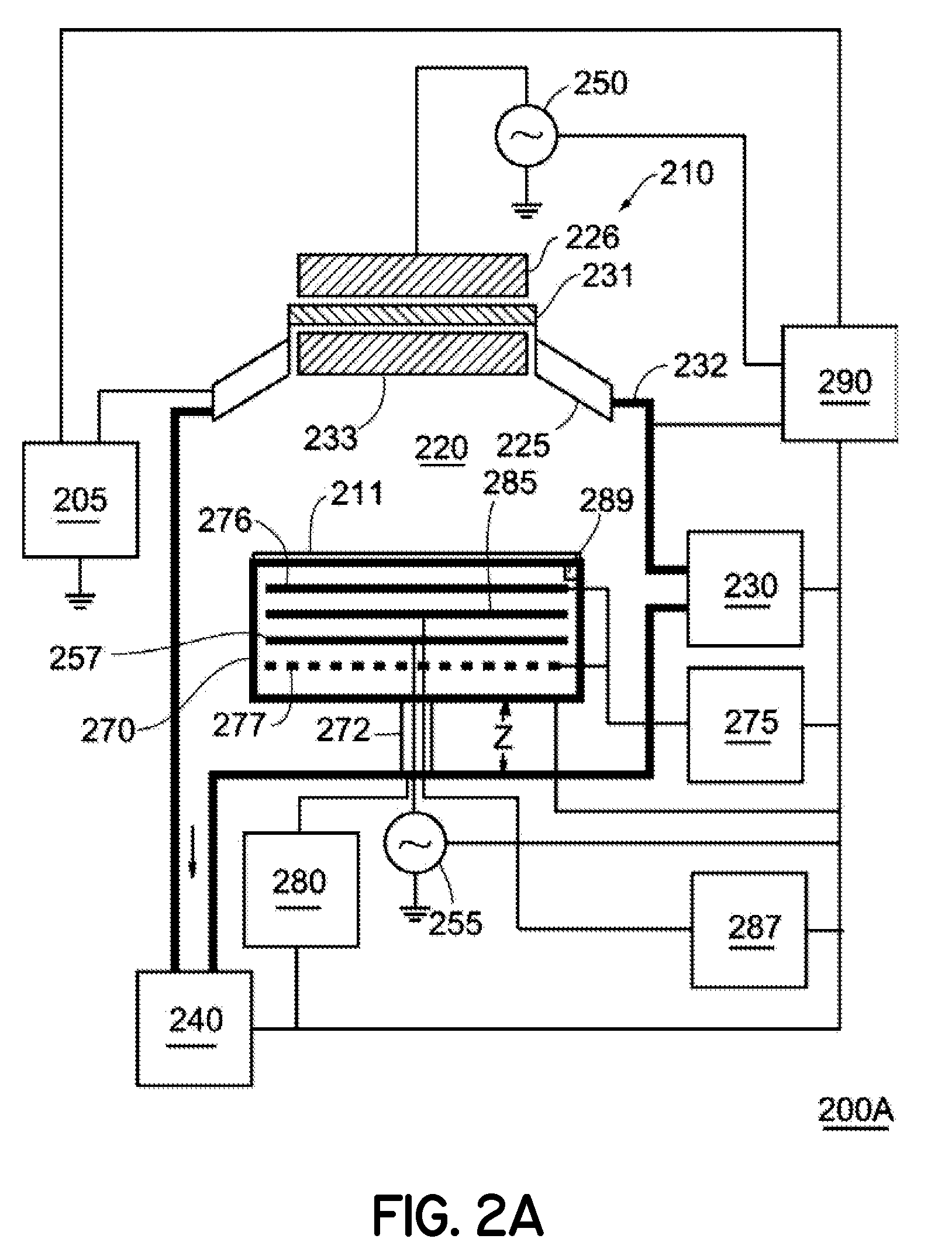

An iPVD system uses a high density inductively coupled plasma (ICP) at high pressure of at least 50 mTorr to deposit uniform ultra-thin layer of a tantalum nitride material barrier material onto the sidewalls of high aspect ratio nano-size features on semiconductor substrates, preferably less than 2 nm thick with less than 4 nm in the field areas. The process includes depositing an ultra-thin TaN barrier layer having a high nitrogen concentration that produces high resistivity, preferably at least 1000 micro-ohm-cm. The ultra-thin TaN film is deposited by a low deposition rate process of less than 20 nm / minute, preferably 2-10 nm / min, to produce the high N / Ta ratio layer without nitriding the tantalum target. The layer provides a barrier to copper (Cu) diffusion and a high etch resistant etch-stop layer for subsequent deposition-etch processes.

Owner:TOKYO ELECTRON LTD

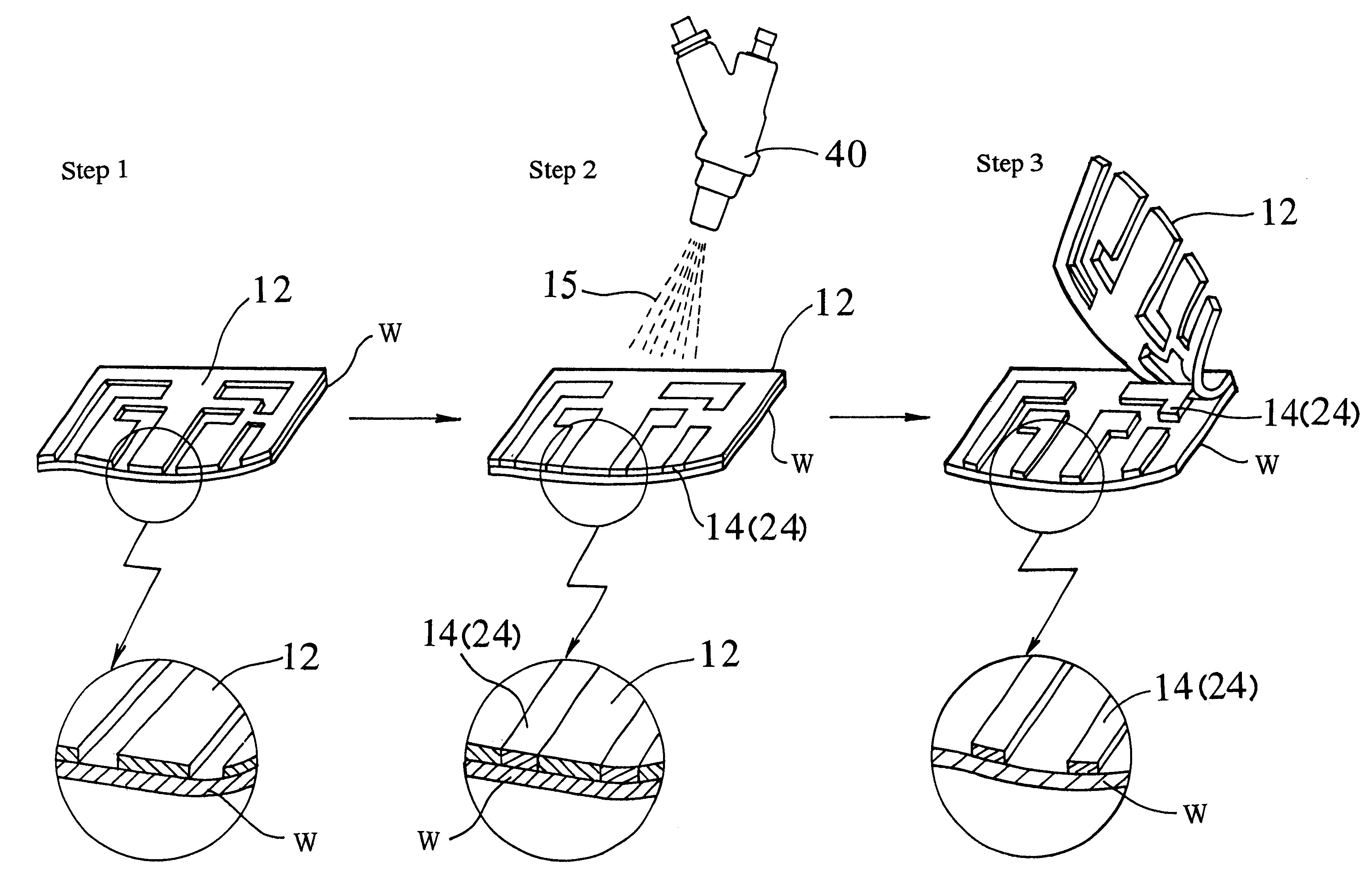

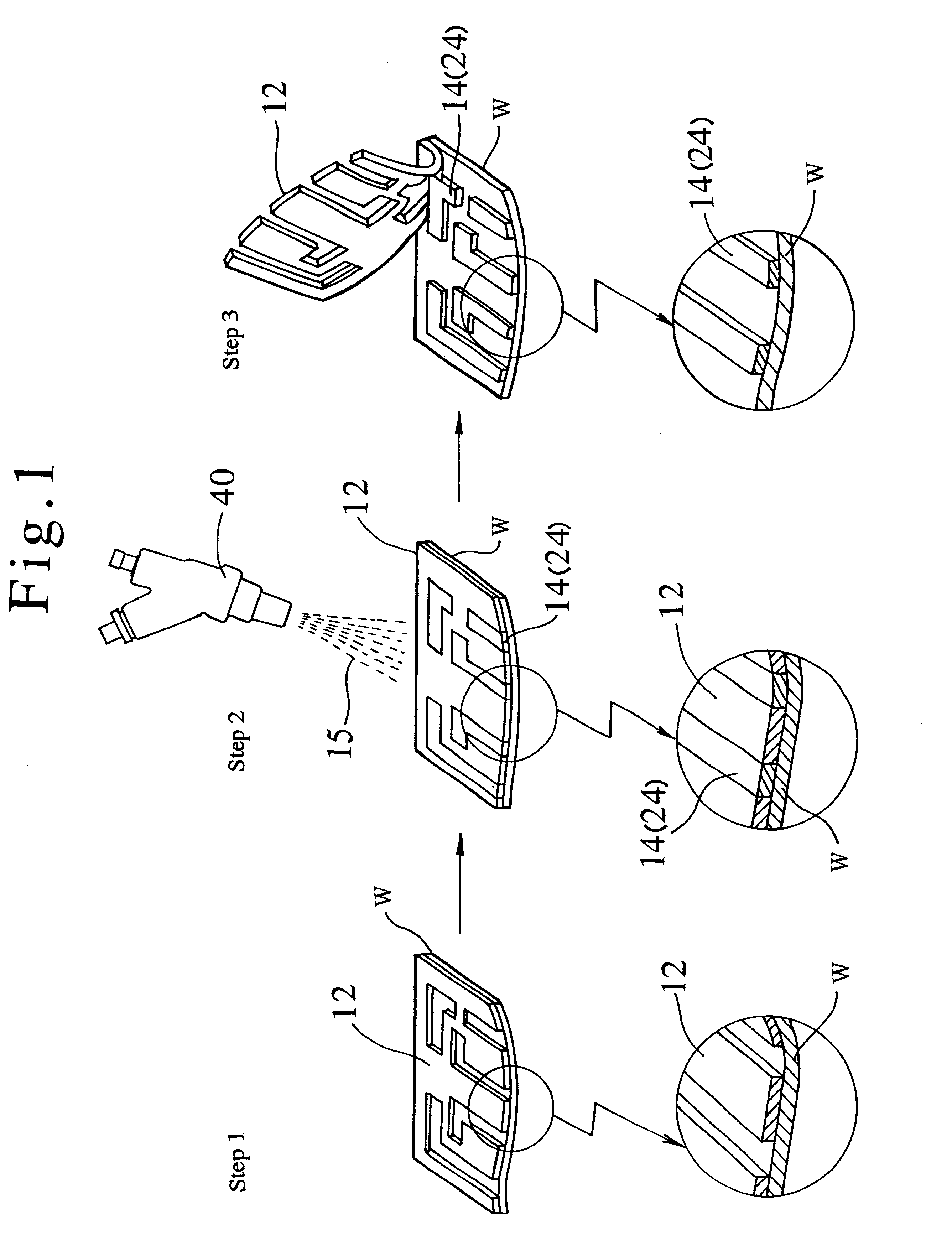

Method for forming a metallic coat by impacting metallic particles on a workpiece

InactiveUS6291012B1Prevent nitridingHigh densityPretreated surfacesSolid state diffusion coatingAbrasive blastingUltimate tensile strength

Method for forming metallic coat where, the surface of workpiece is partly covered with a masking material having a predetermined pattern, and metallic powders are ejected to the surface at the ejection velocity of 80 m / sec or higher or at the ejection pressure of 0.3 Mpa or higher by utilizing an ejection apparatus such as blast work apparatus, in order to easily attain the metallic coat having high adhesion strength without washing process, nor heat process by a relatively simple facility.

Owner:FUJI KIHAN CO LTD

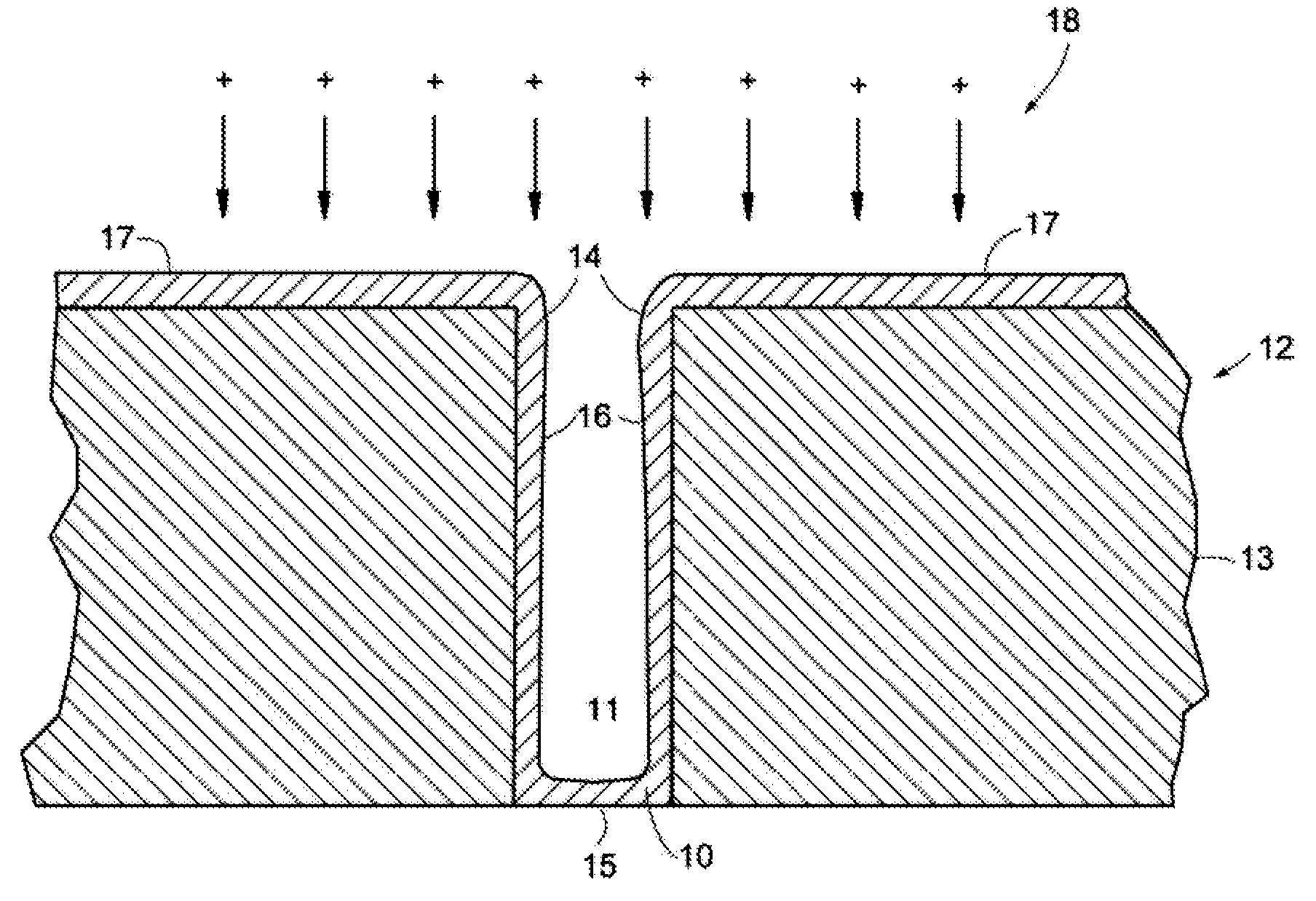

Barrier deposition using ionized physical vapor deposition (iPVD)

InactiveUS7700474B2Prevent nitridingElectric discharge tubesVacuum evaporation coatingHigh densityTantalum nitride

An iPVD system uses a high density inductively coupled plasma (ICP) at high pressure of at least 50 mTorr to deposit uniform ultra-thin layer of a tantalum nitride material barrier material onto the sidewalls of high aspect ratio nano-size features on semiconductor substrates, preferably less than 2 nm thick with less than 4 nm in the field areas. The process includes depositing an ultra-thin TaN barrier layer having a high nitrogen concentration that produces high resistivity, preferably at least 1000 micro-ohm-cm. The ultra-thin TaN film is deposited by a low deposition rate process of less than 20 nm / minute, preferably 2-10 nm / min, to produce the high N / Ta ratio layer without nitriding the tantalum target. The layer provides a barrier to copper (Cu) diffusion and a high etch resistant etch-stop layer for subsequent deposition-etch processes.

Owner:TOKYO ELECTRON LTD

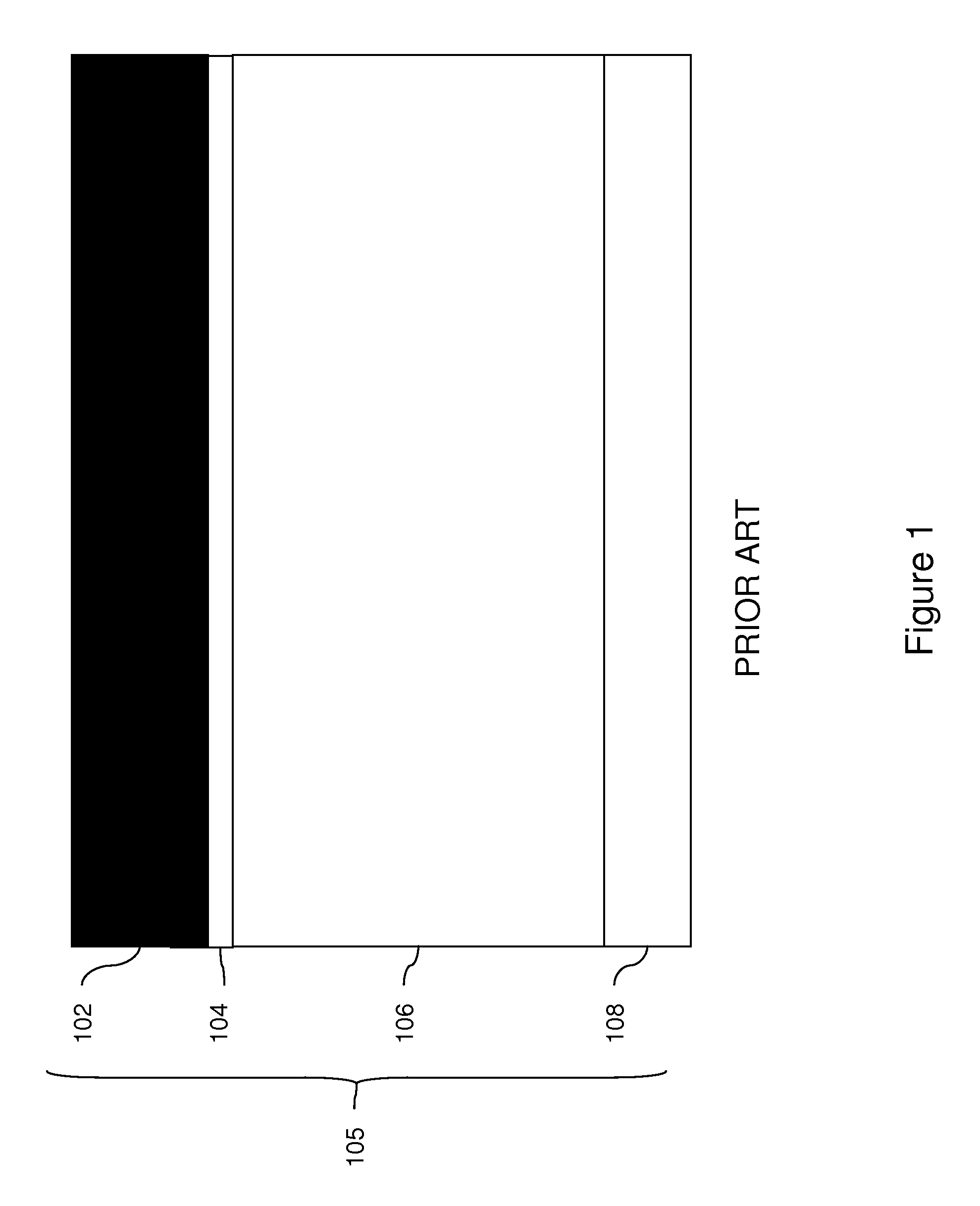

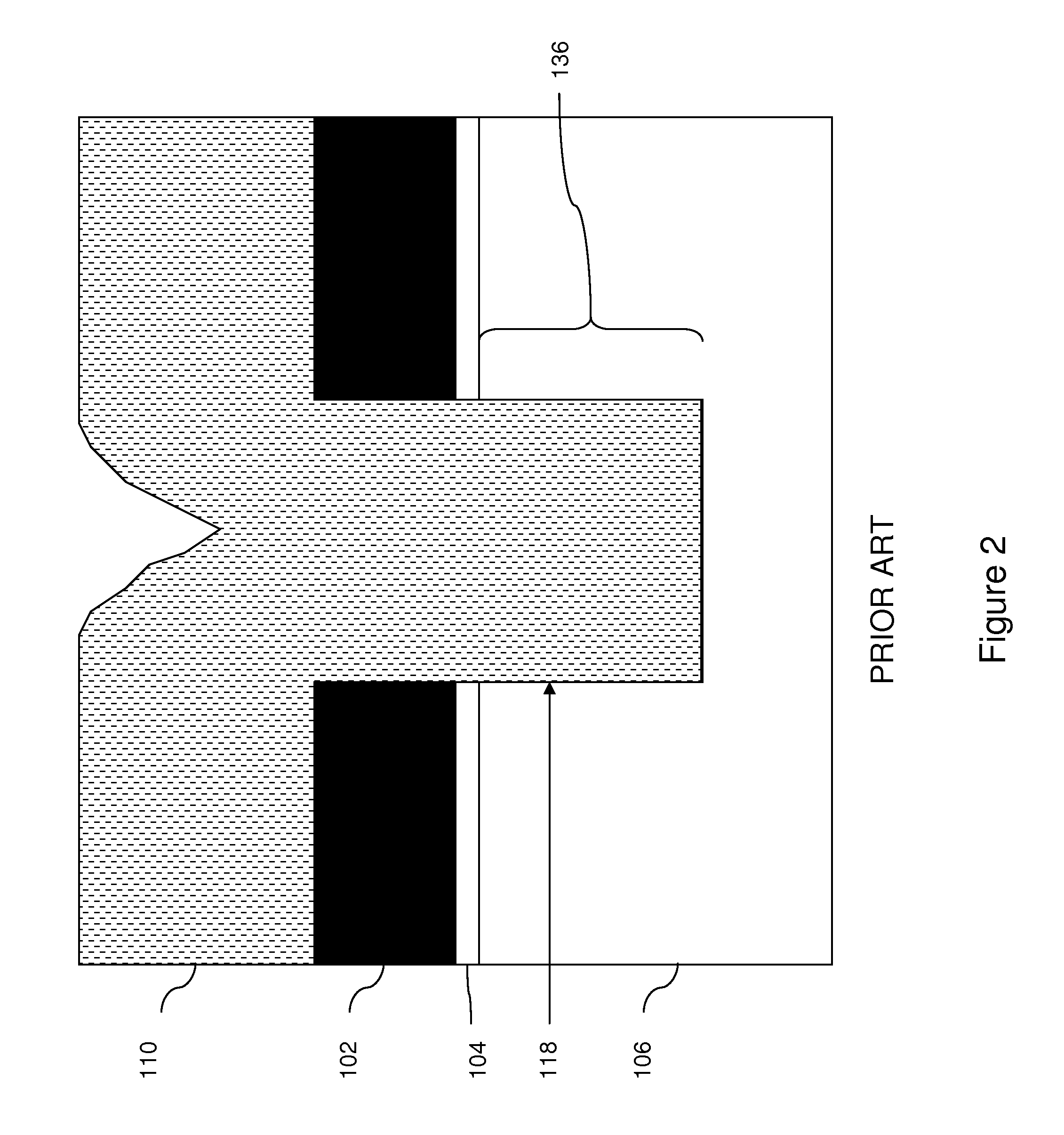

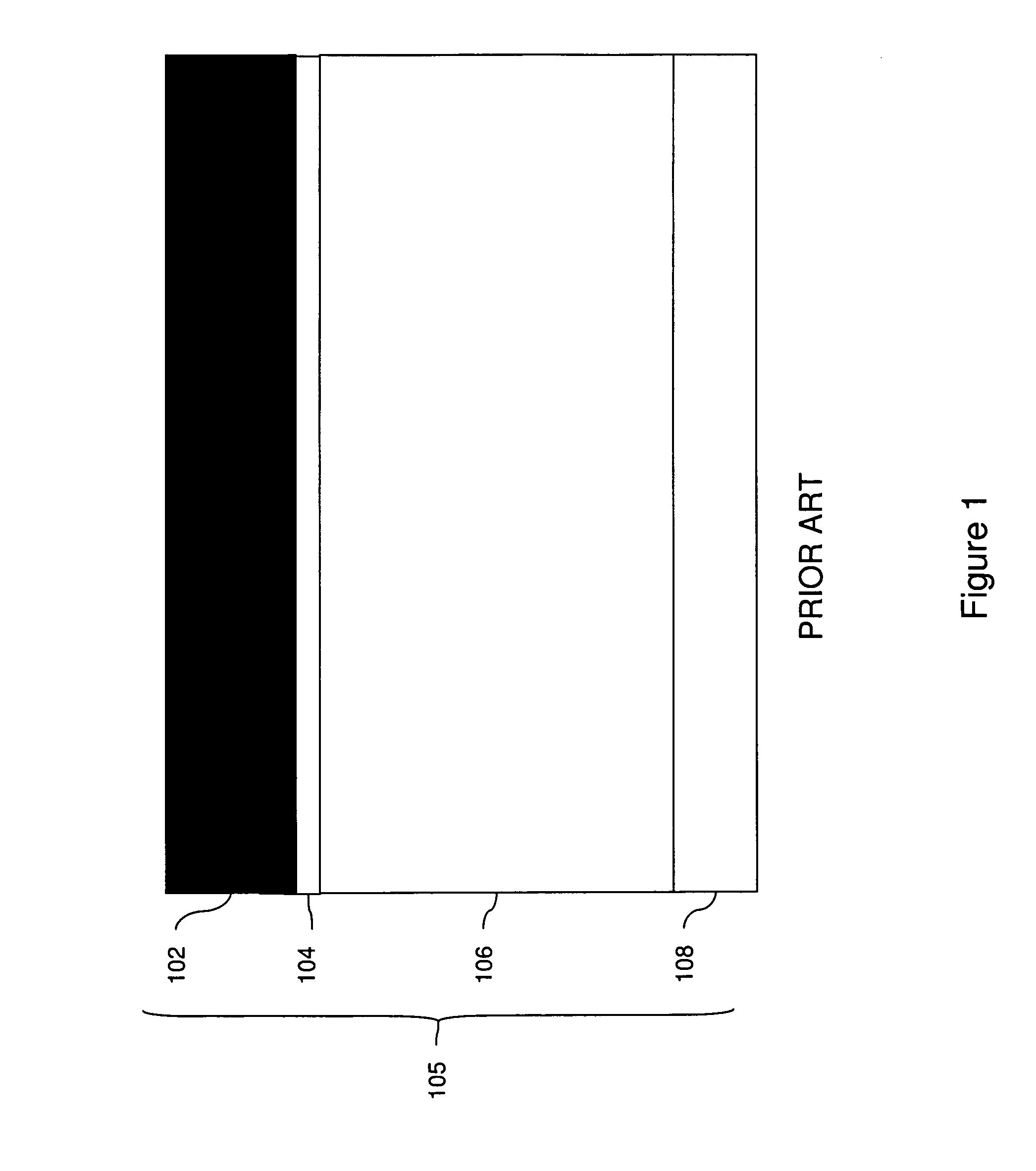

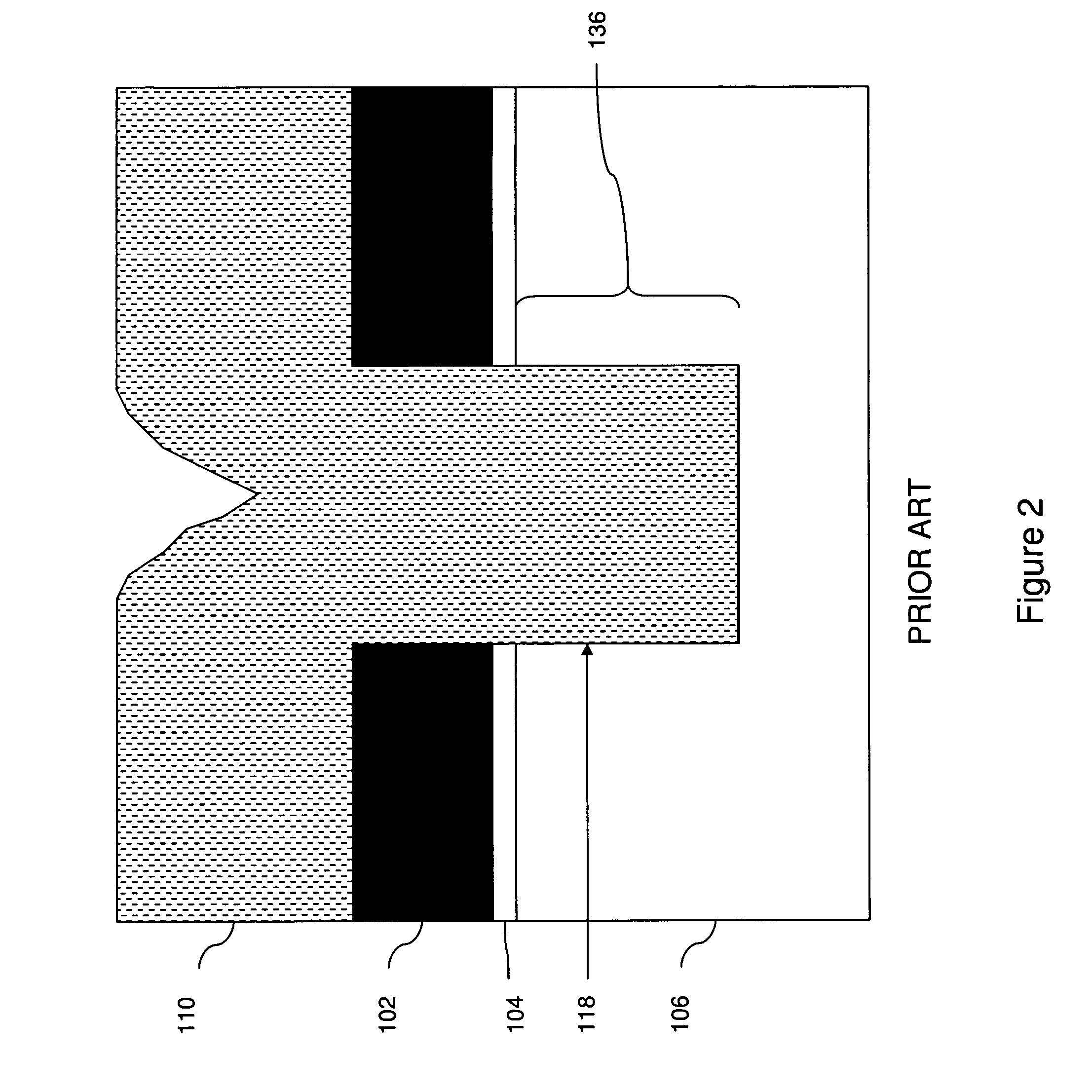

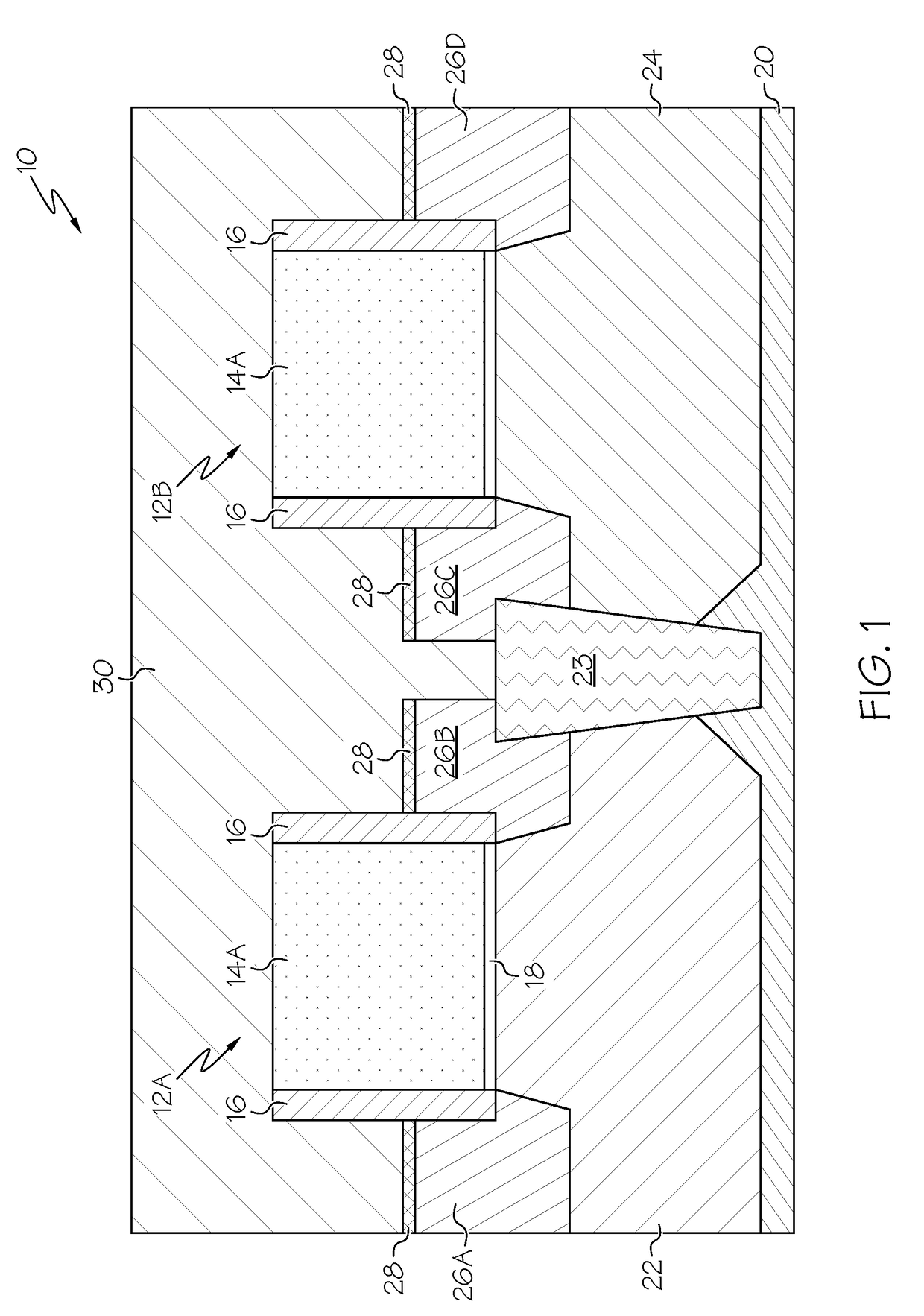

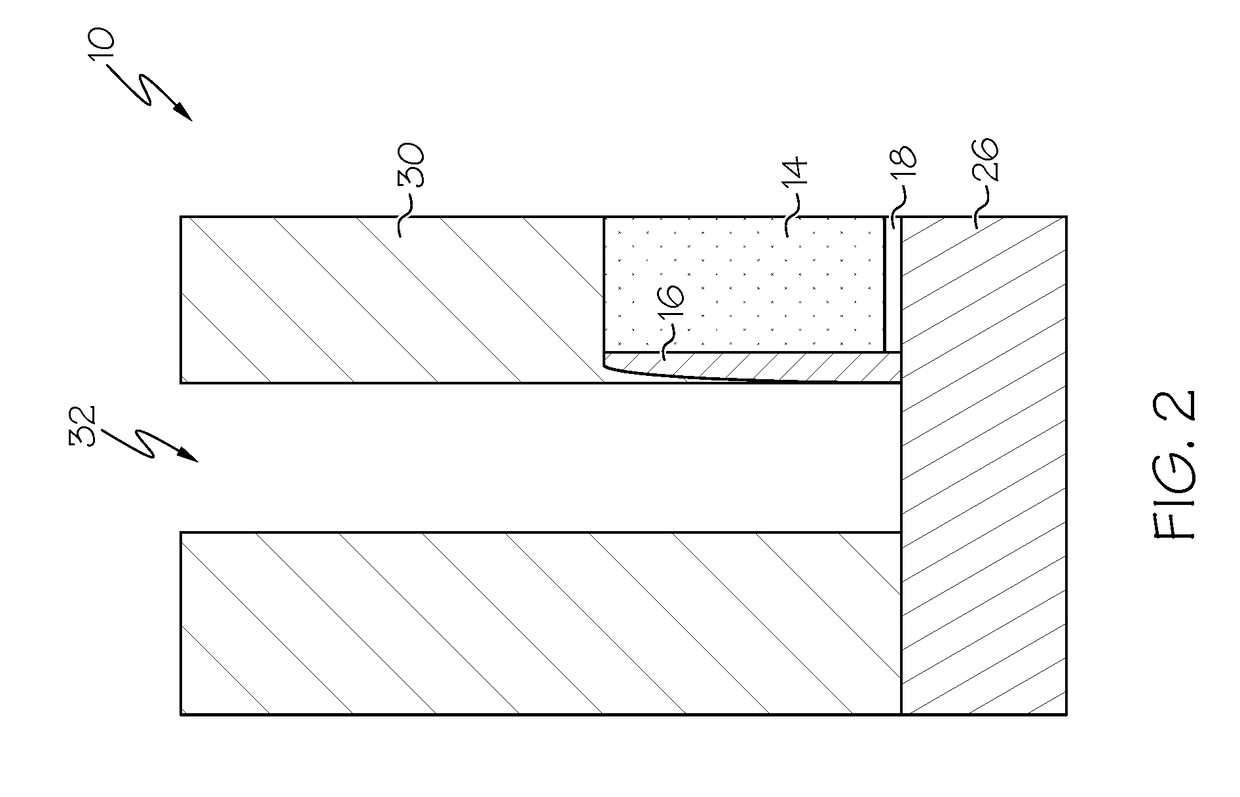

Nitridation of STI fill oxide to prevent the loss of STI fill oxide during manufacturing process

InactiveUS20060160322A1Reduce erosionReduce formationTransistorSemiconductor/solid-state device manufacturingHigh concentrationEtching

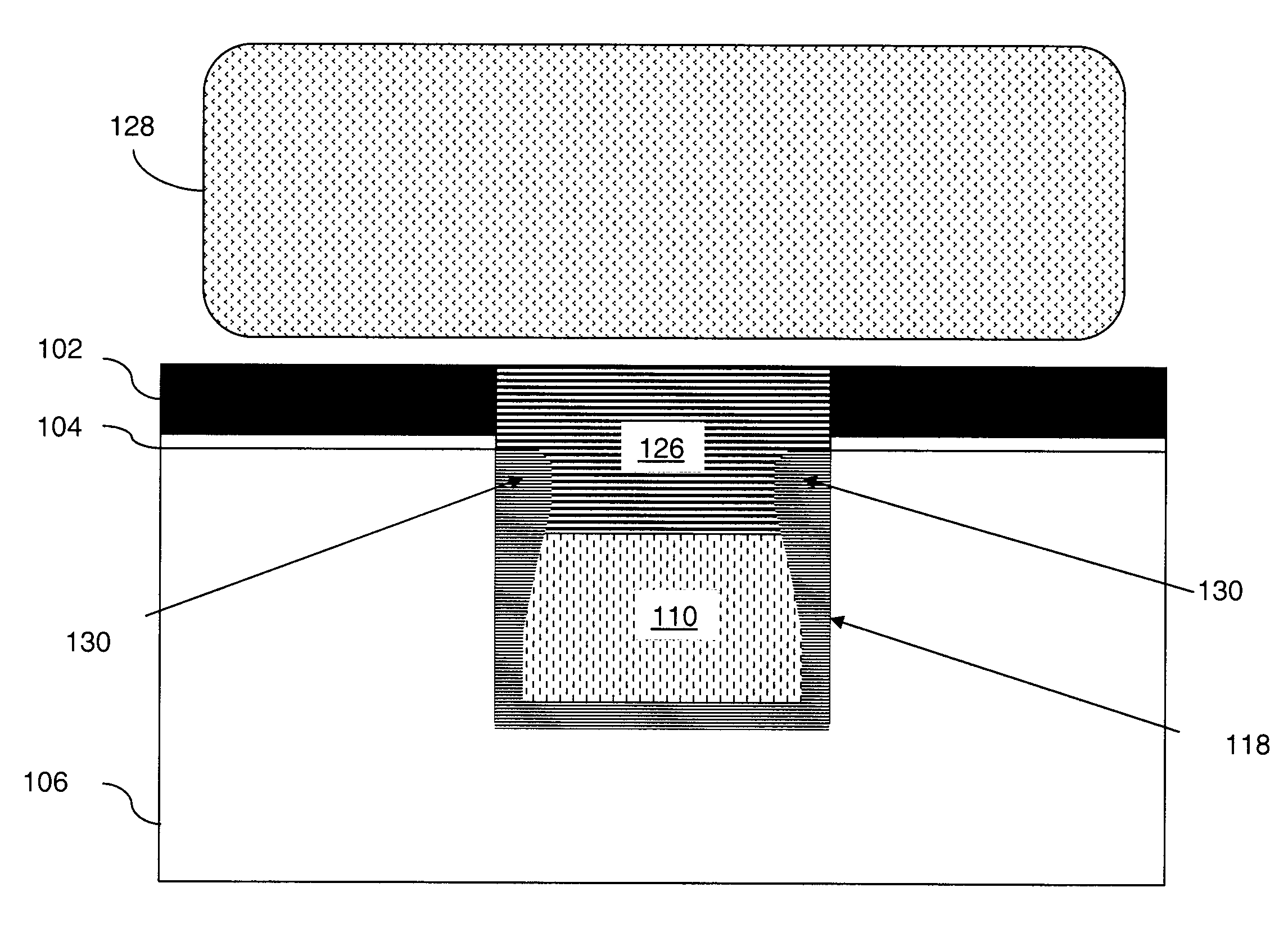

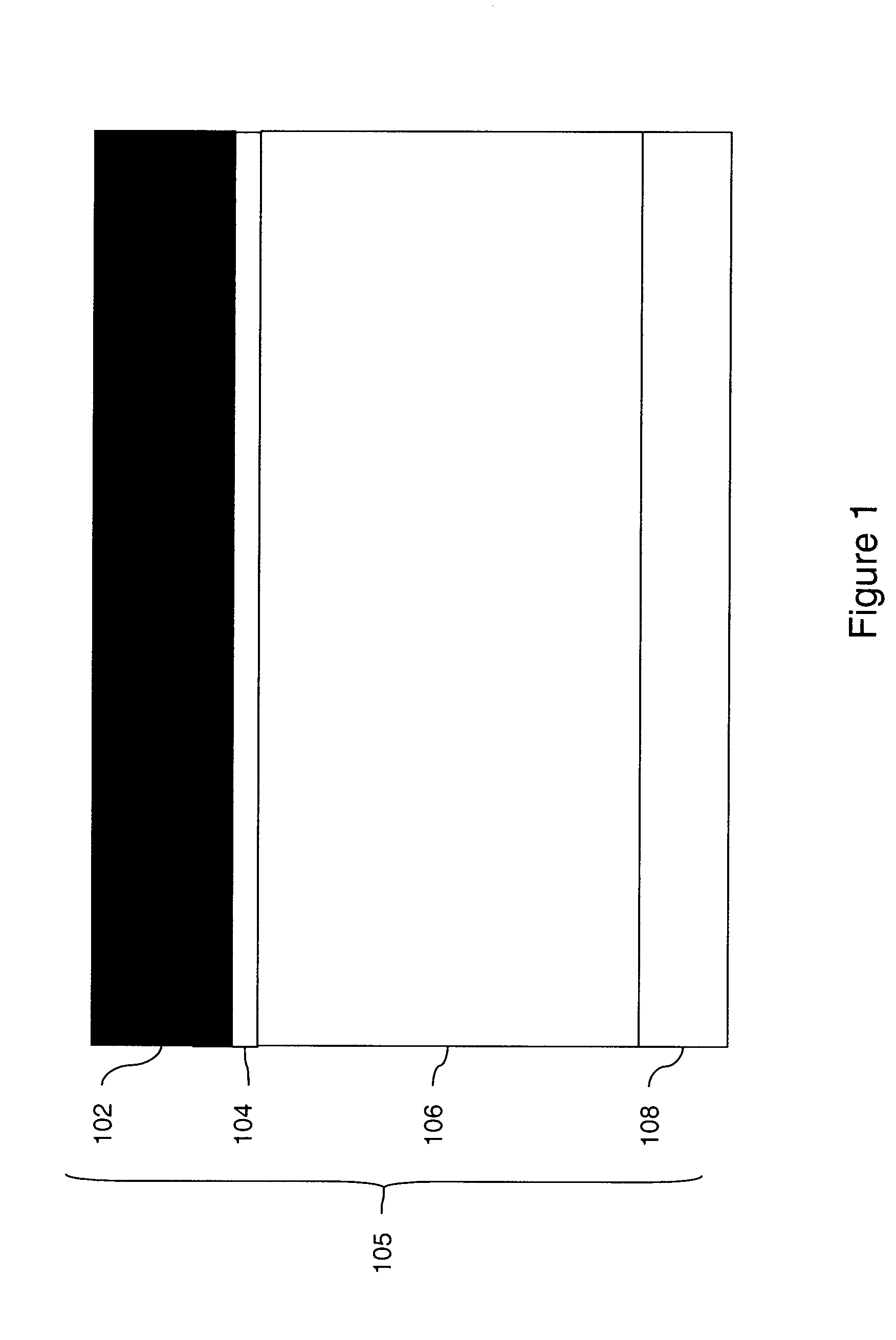

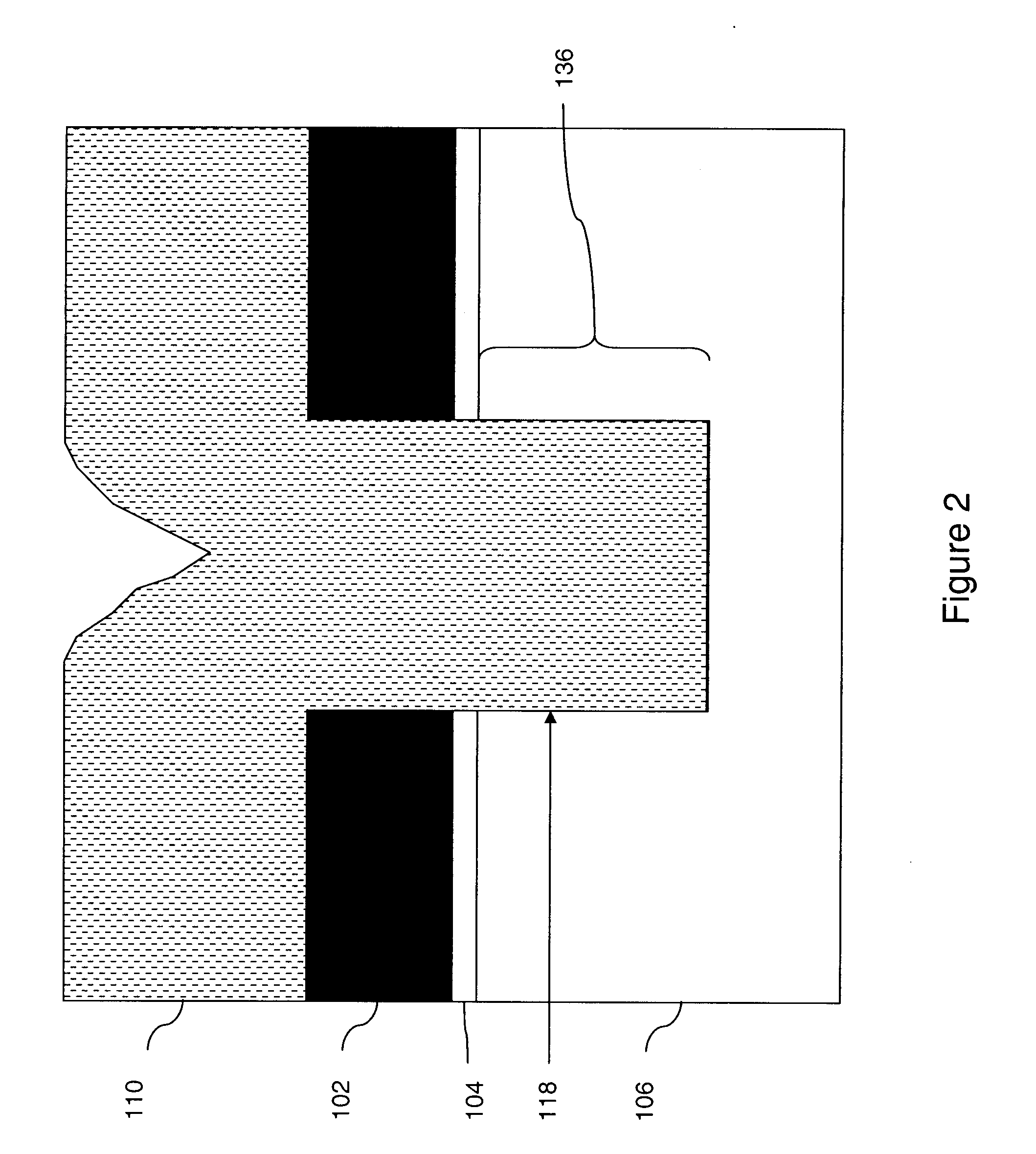

A method and structure for an improved shallow trench isolation (STI) structure for a semiconductor device. The STI structure incorporates an oxynitride top layer of the STI fill. Optionally, the STI structure incorporates an oxynitride margin of the STI fill adjacent the silicon trench walls. A region of the oxynitride margin near the upper edges of the silicon trench walls includes oxynitride corners that are relatively thicker and contain a higher concentration of nitrogen as compared to the other regions of the oxynitride margin. The oxynitride features limit the STI fill height loss and also reduce the formation of divots in the STI fill below the level of the silicon substrate cause by hydrofluoric acid etching and other fabrication processes. Limiting STI fill height loss and the formation of divots improves the functions of the STI structure. The method of forming the STI structure is particularly compatible with standard semiconductor device fabrication processes, including chemical mechanical polishing (CMP), because the method incorporates the use of a pure silicon dioxide STI fill and plasma and thermal nitridation processes to form the oxynitride top layer and oxynitride margin, including the oxynitride corners, of the STI fill.

Owner:IBM CORP

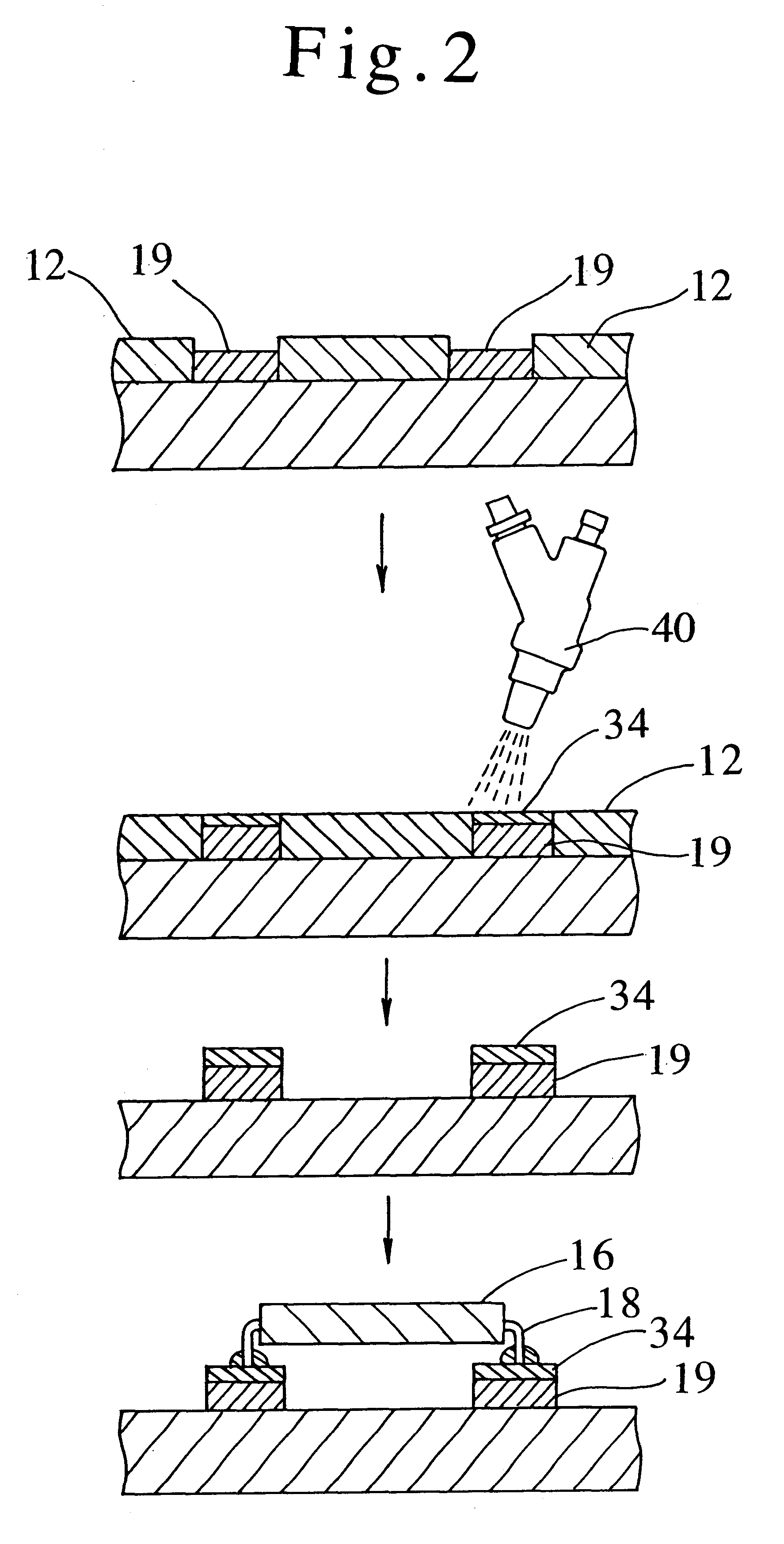

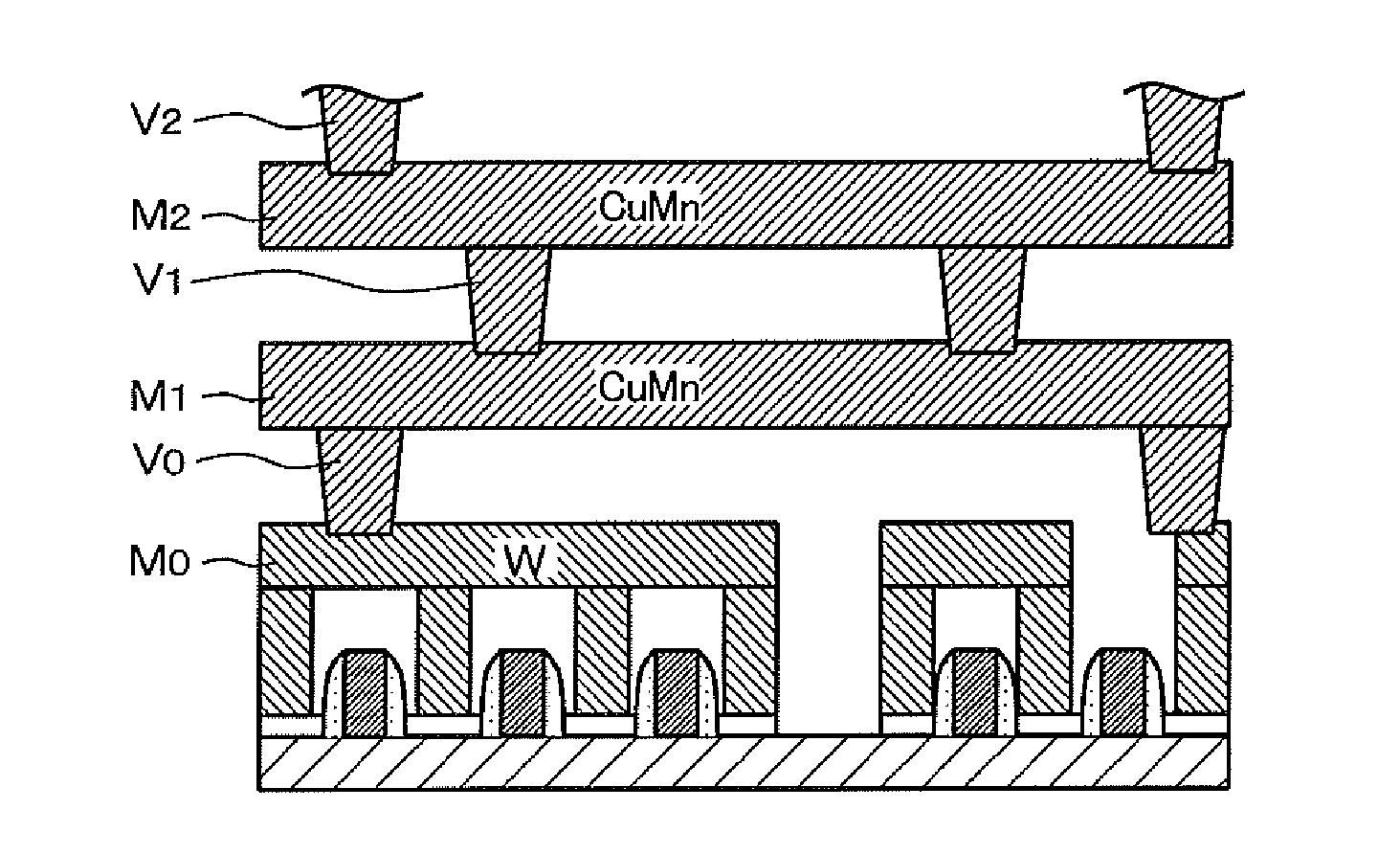

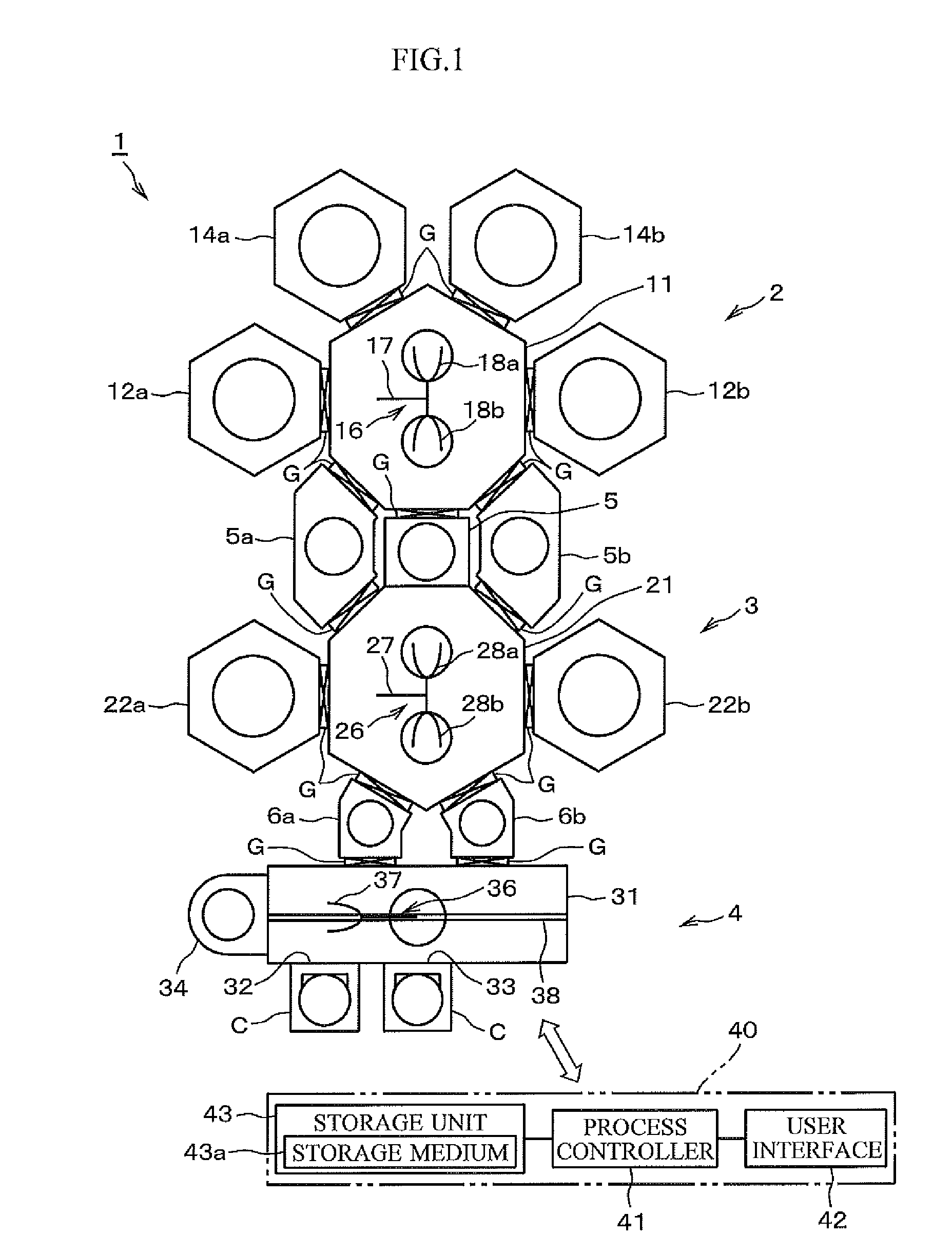

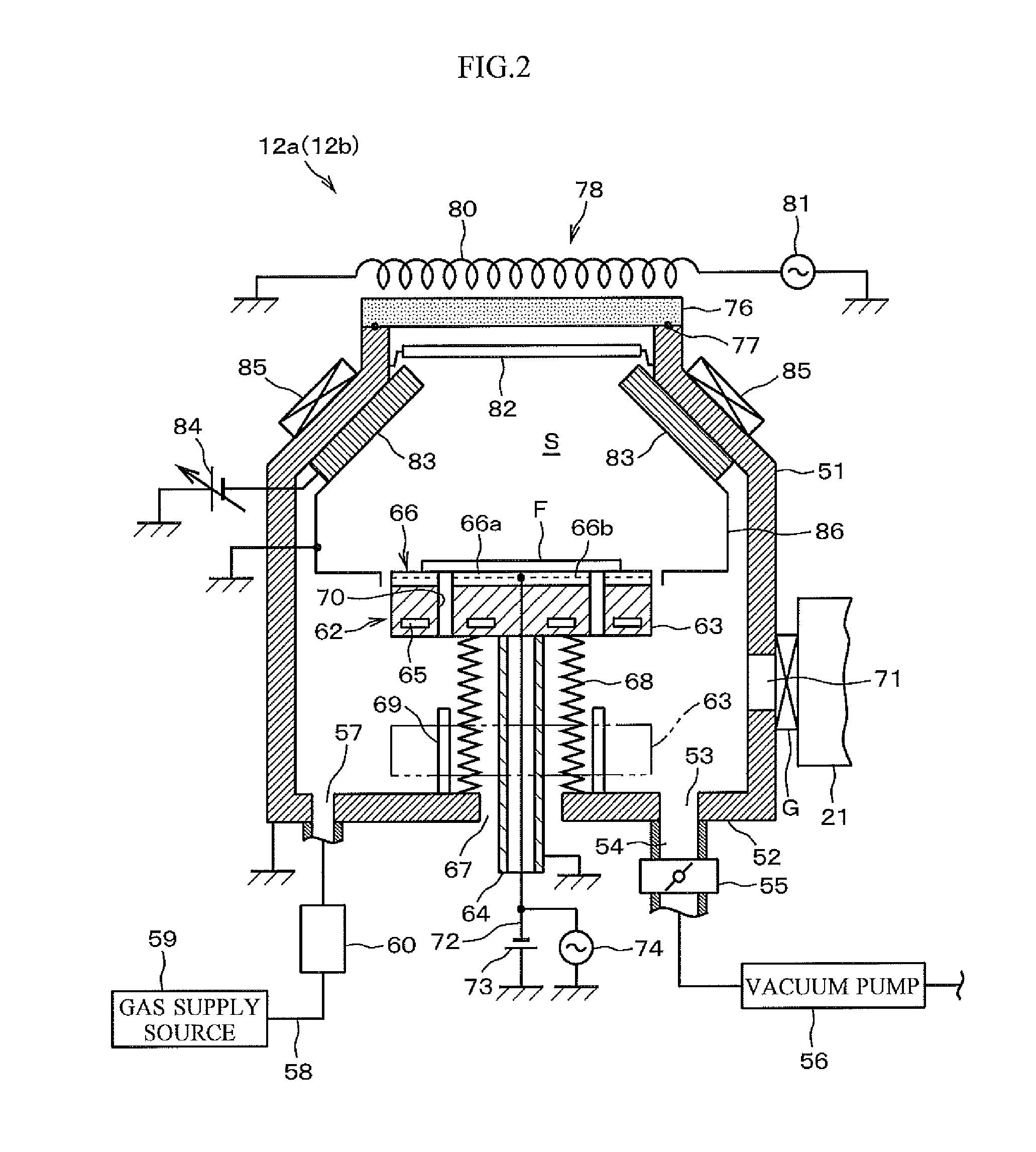

Copper wiring forming method, film forming system, and storage medium

ActiveUS20160163591A1Reduced via resistanceLower resistanceCellsLiquid surface applicatorsMetallurgyCopper-wiring

A Cu wiring forming method of forming Cu wiring that is to be arranged in contact with tungsten wiring, by filling Cu into a recess formed in a substrate, includes: removing a tungsten oxide formed on a surface of the tungsten wiring; forming a nitriding preventing film at least on the surface of the tungsten wiring in the recess; forming a barrier film that prevents diffusion of Cu, on a surface in the recess from above the nitriding preventing film; forming a liner film on the barrier film; and filling a Cu film on the liner film.

Owner:TOKYO ELECTRON LTD

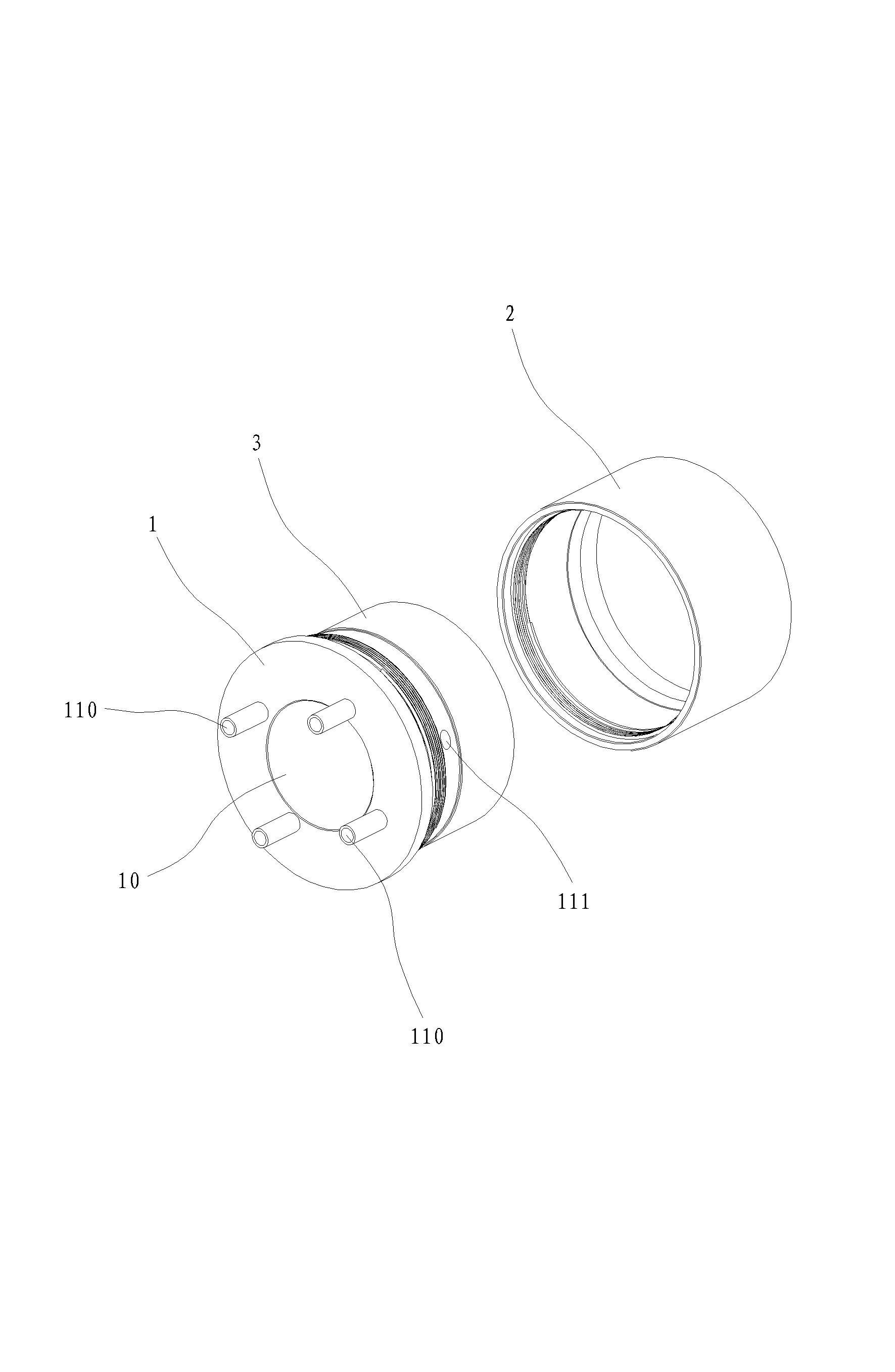

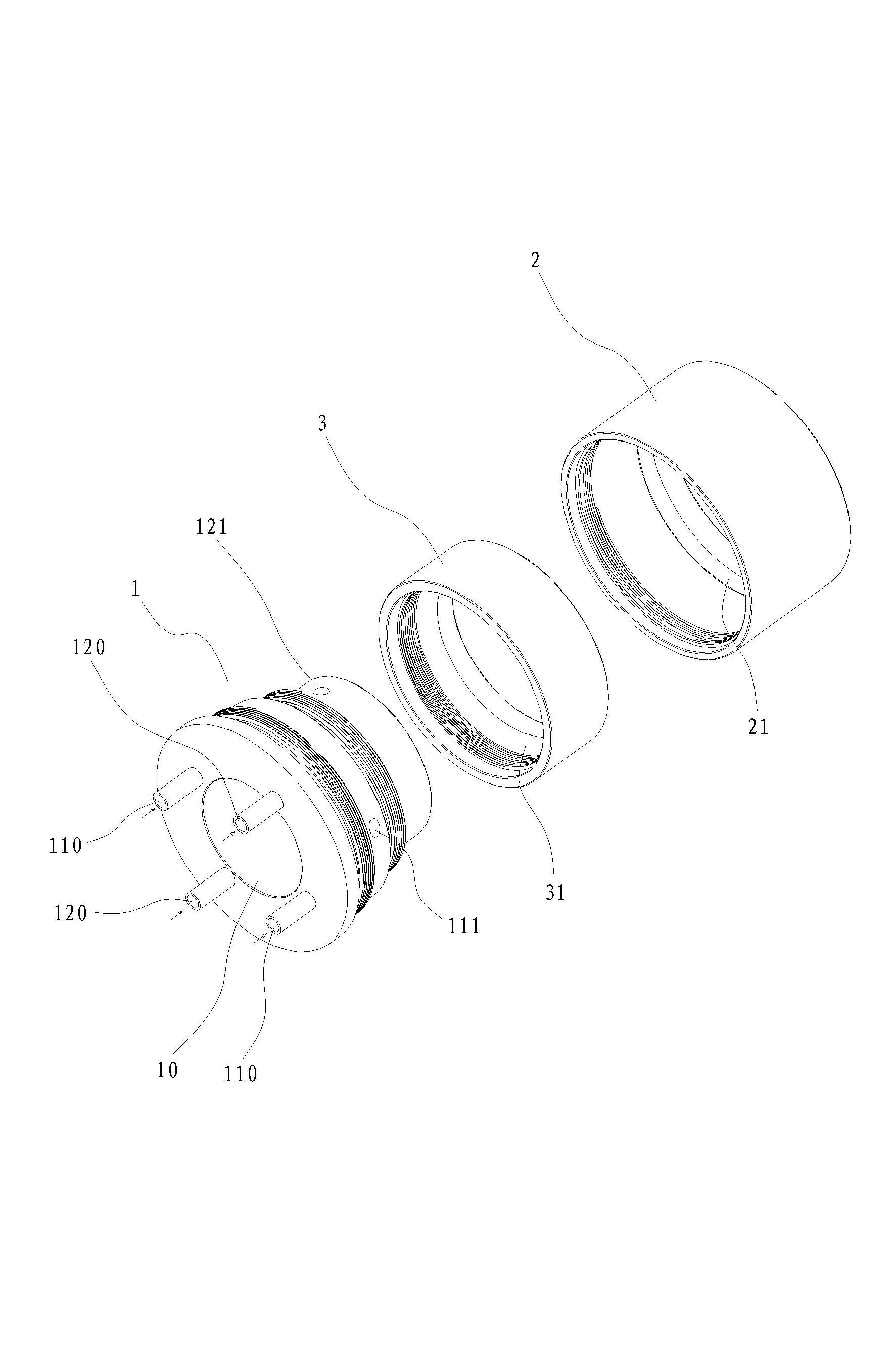

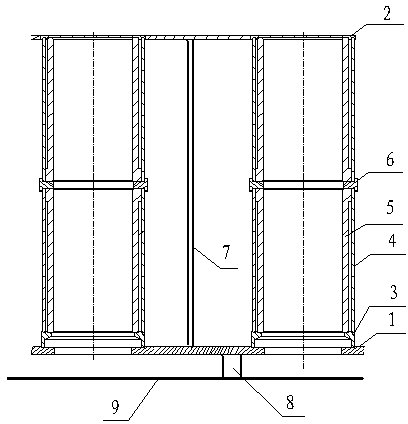

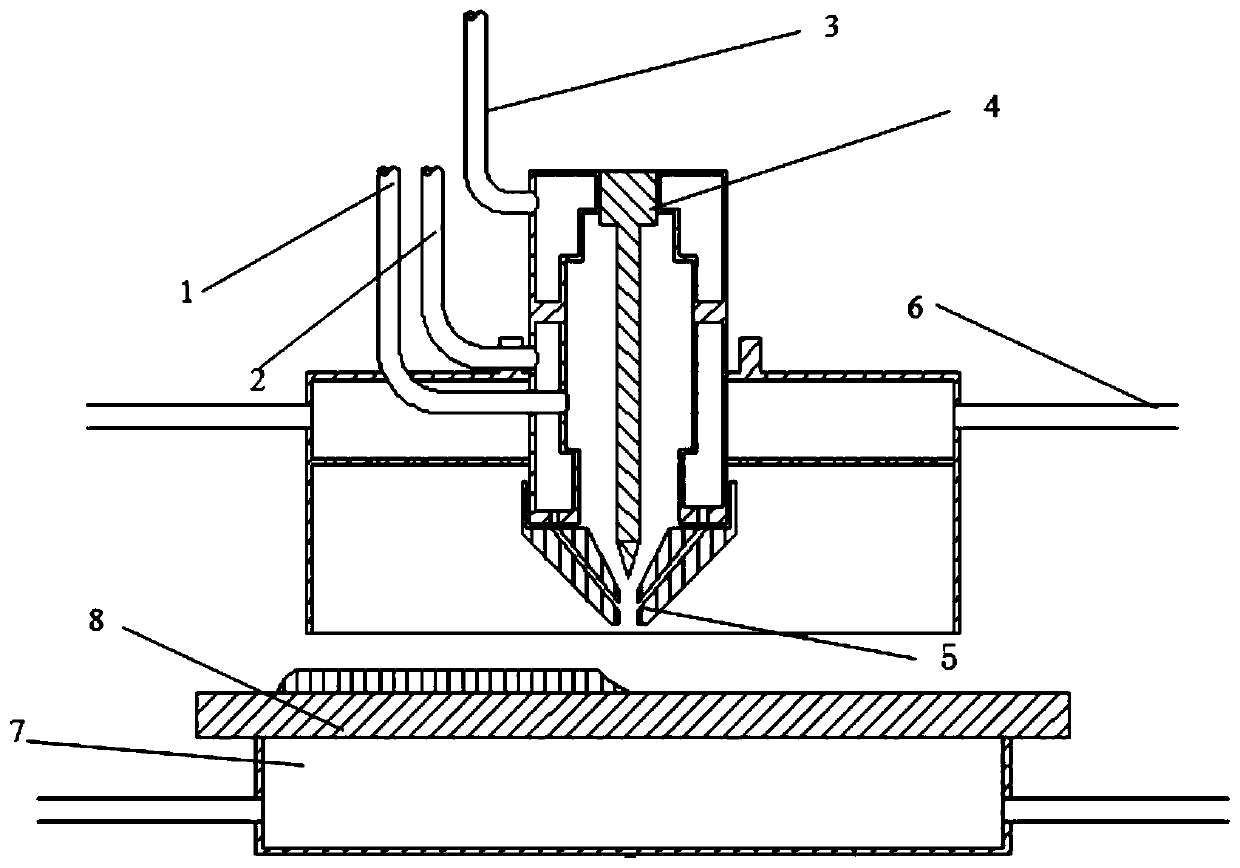

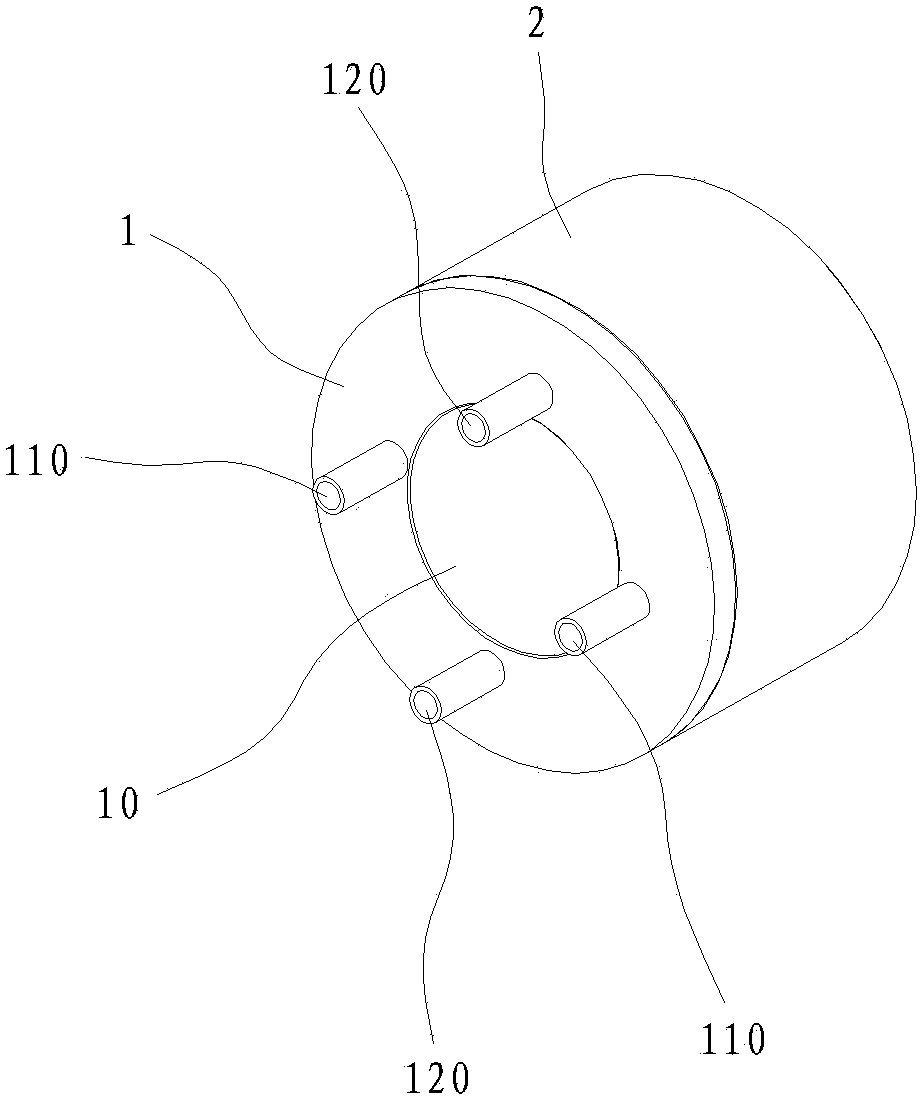

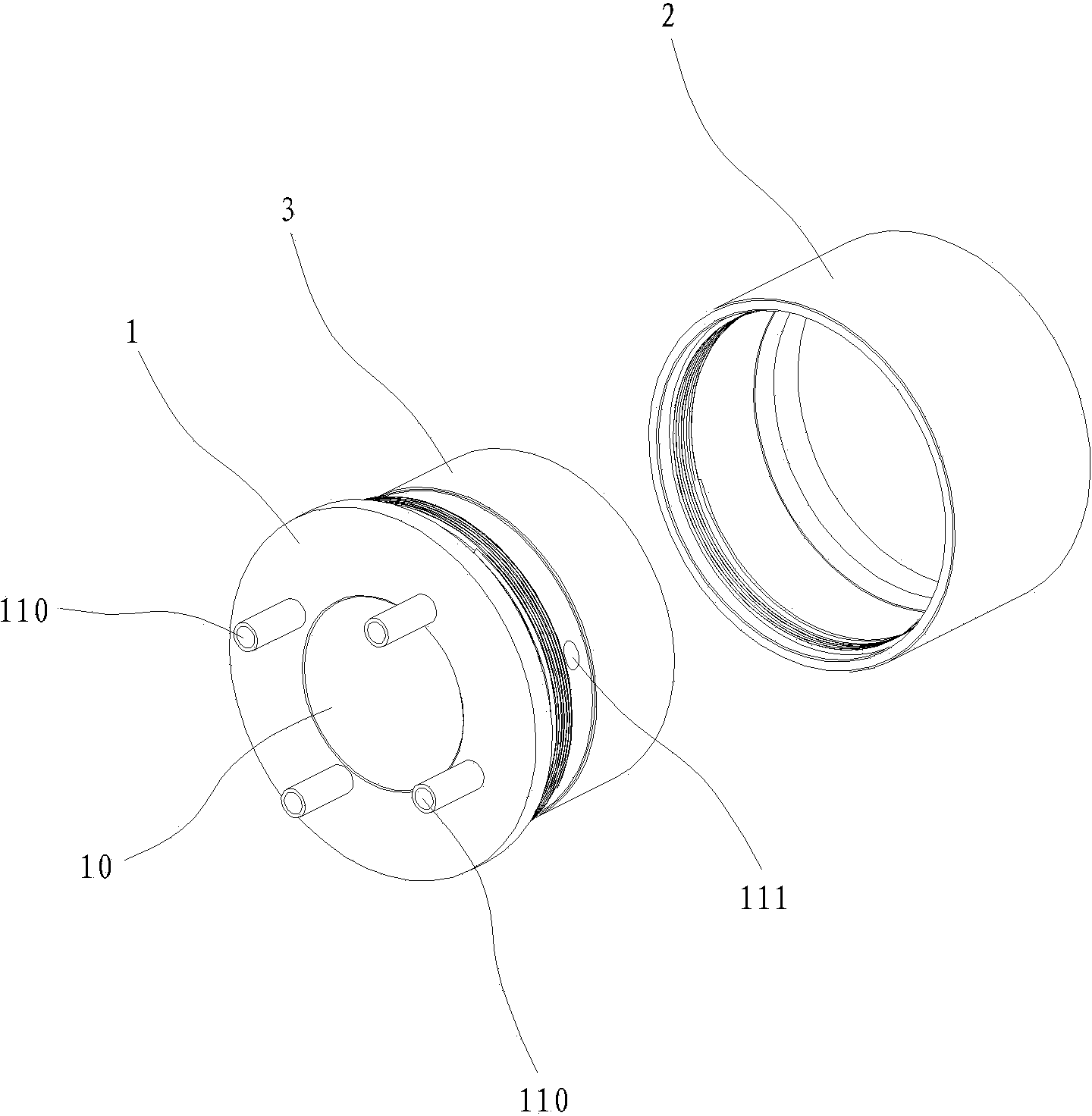

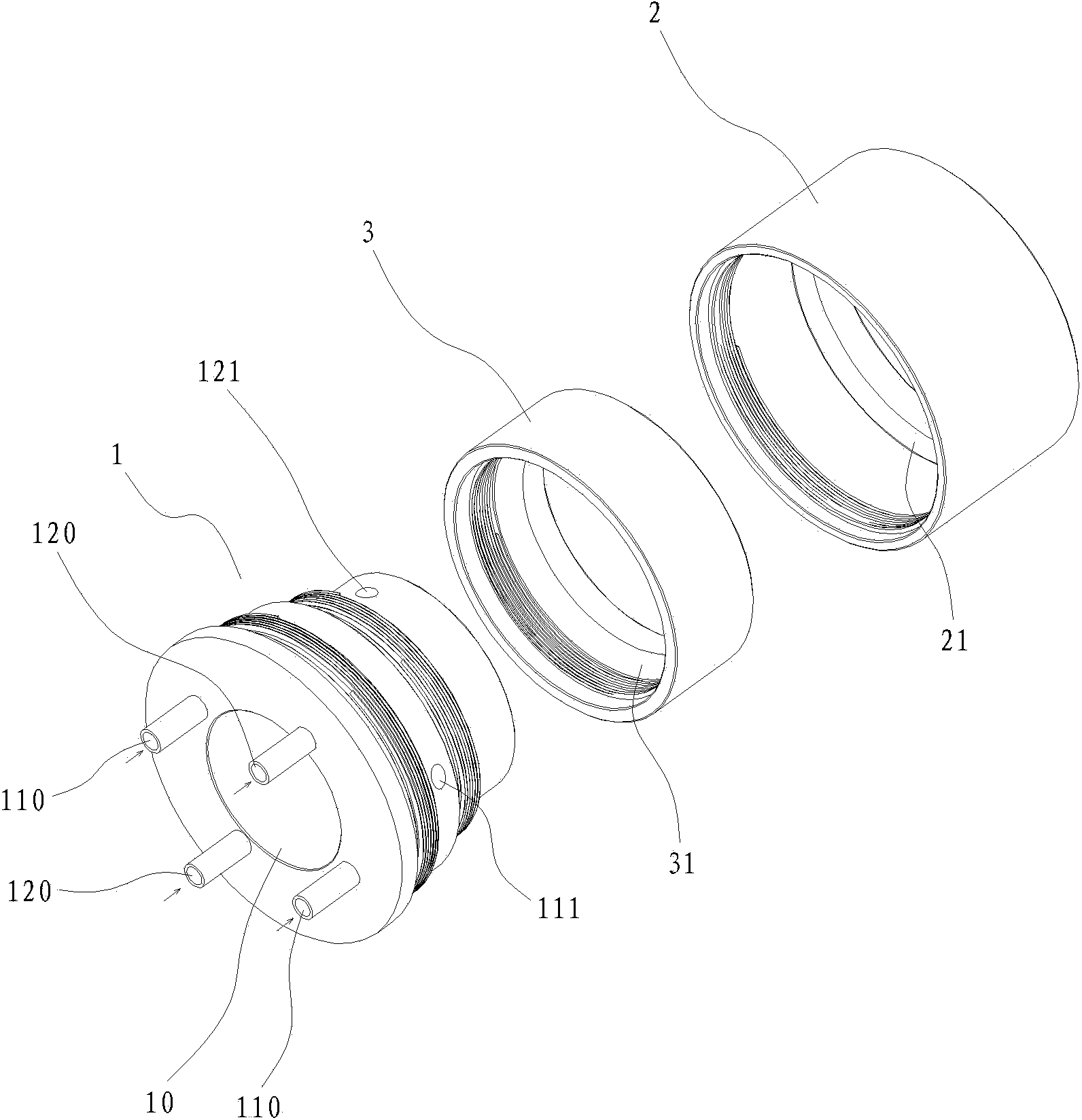

Plasma jet-stream protective cover

InactiveCN102618815APrevent getting involvedPrevent oxidationMolten spray coatingPlasma jetEngineering

The invention discloses a plasma jet-stream protective cover, which comprises a jet-stream core body and a jet-stream core body center axial direction through hole. One end face of the core body is provided with two groups of air intakes. A core body perisporium is correspondingly provided with two groups of air outtakes. The two groups of air outtakes are communicated with the corresponding air intakes so as to form an inner layer of protection air and an outer layer of protection air. An inner ring is connected to the jet-stream core body and is cooperated with one group of air outtakes on the front end of the core body perisporium. An outer ring is connected to the jet-stream core body and is cooperated with the other group of air outtakes of the core body perisporium. The jet-stream core body, the inner ring and the outer ring are together assembled into a cover structure. One end of the cover structure is used for air suction, and the other end forms two layers of protection air rings and is extended forward so as to enable the plasma jet-stream to be effectively separated from the atmosphere. One protective device is installed on one spray gun of an atmosphere plasma spray coating device, completely-molten or half-molten powder is protected inside the protective air along with the flame through the protection of the air so as to be separated from the atmosphere, the oxidization and nitrogenization of the powder in a high temperature can be reduced, and the quality of a target coating can be improved.

Owner:WUHU YINGRI TECH CO LTD

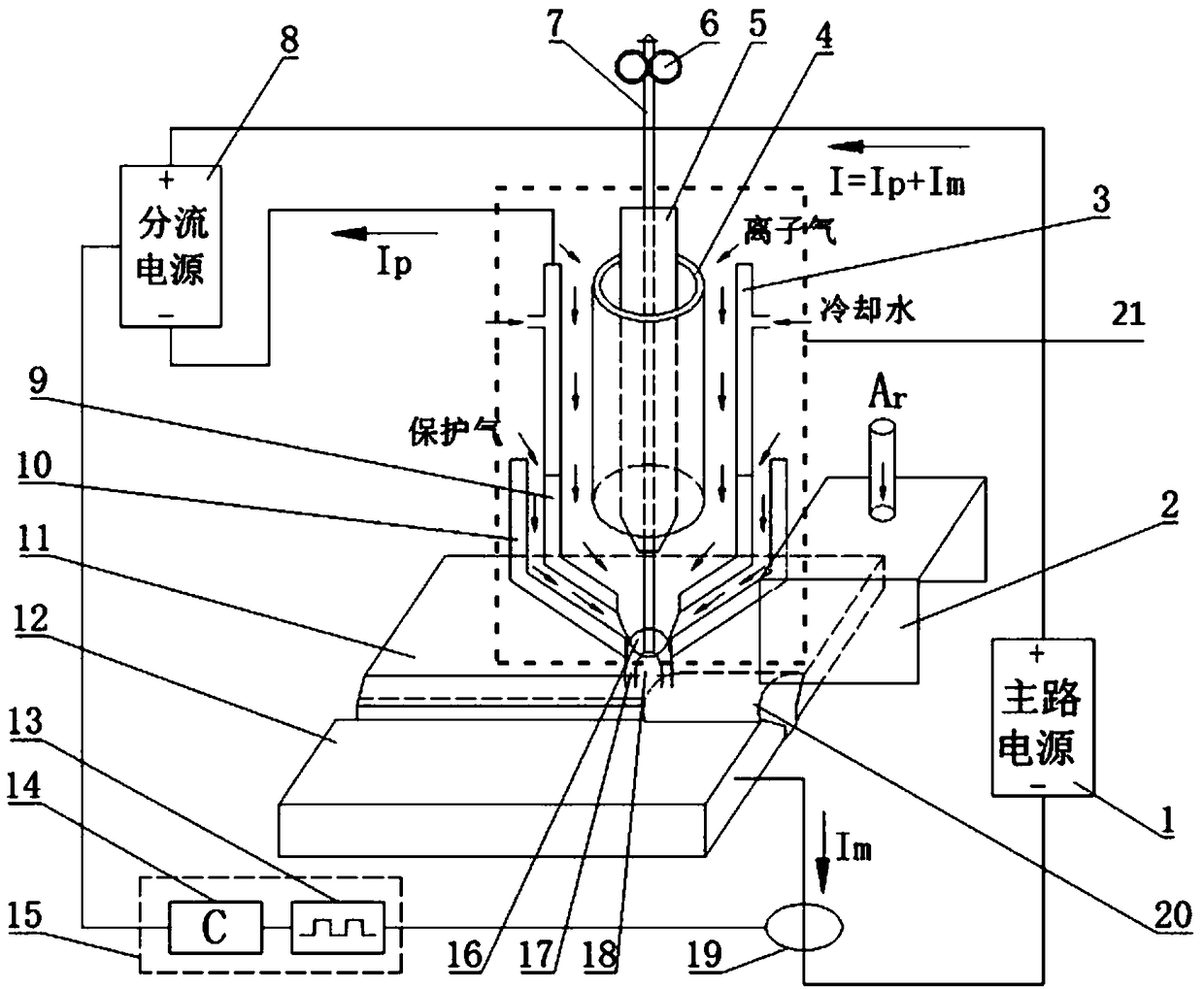

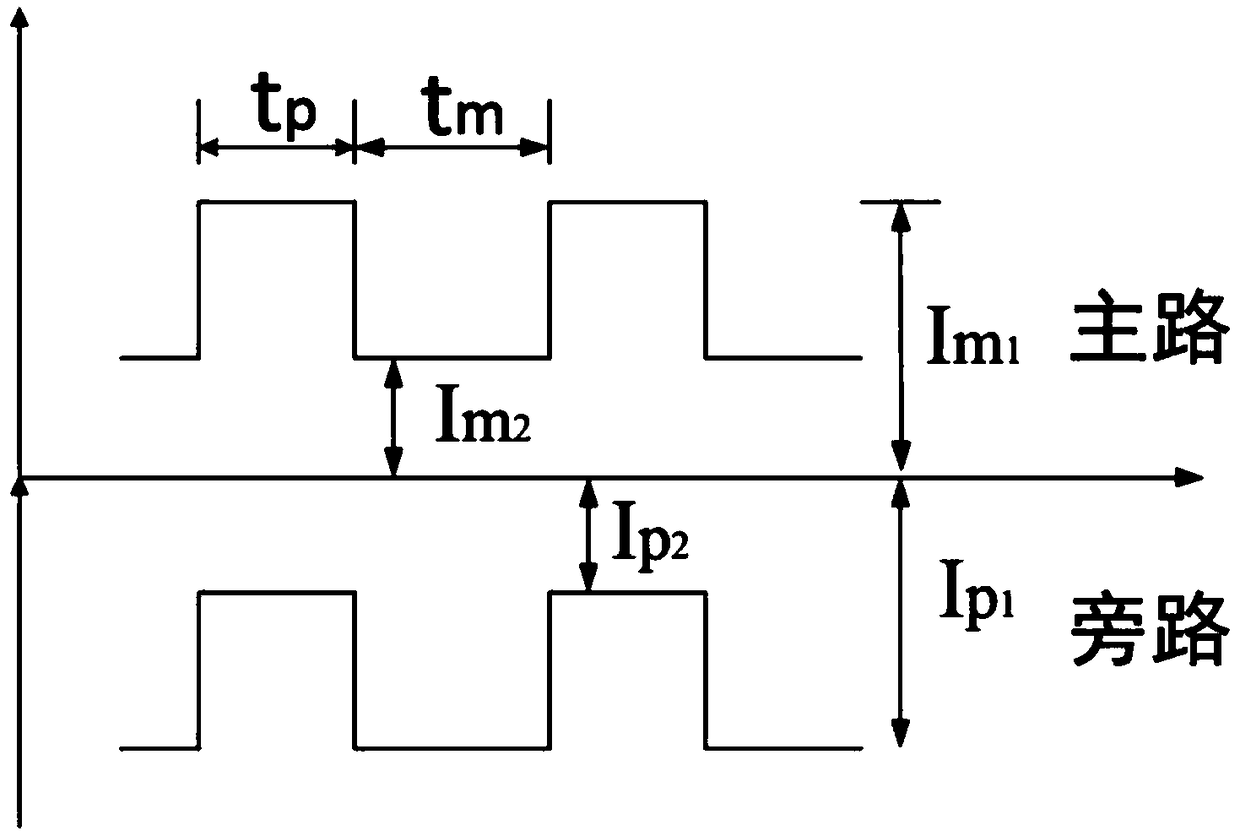

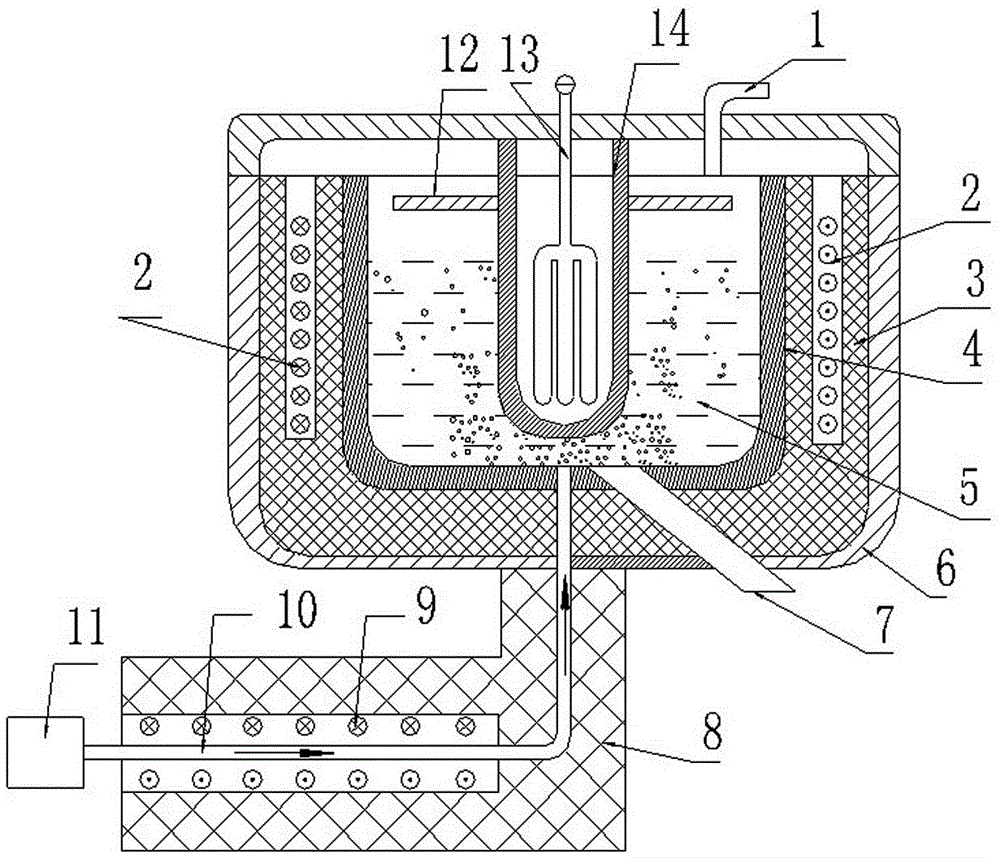

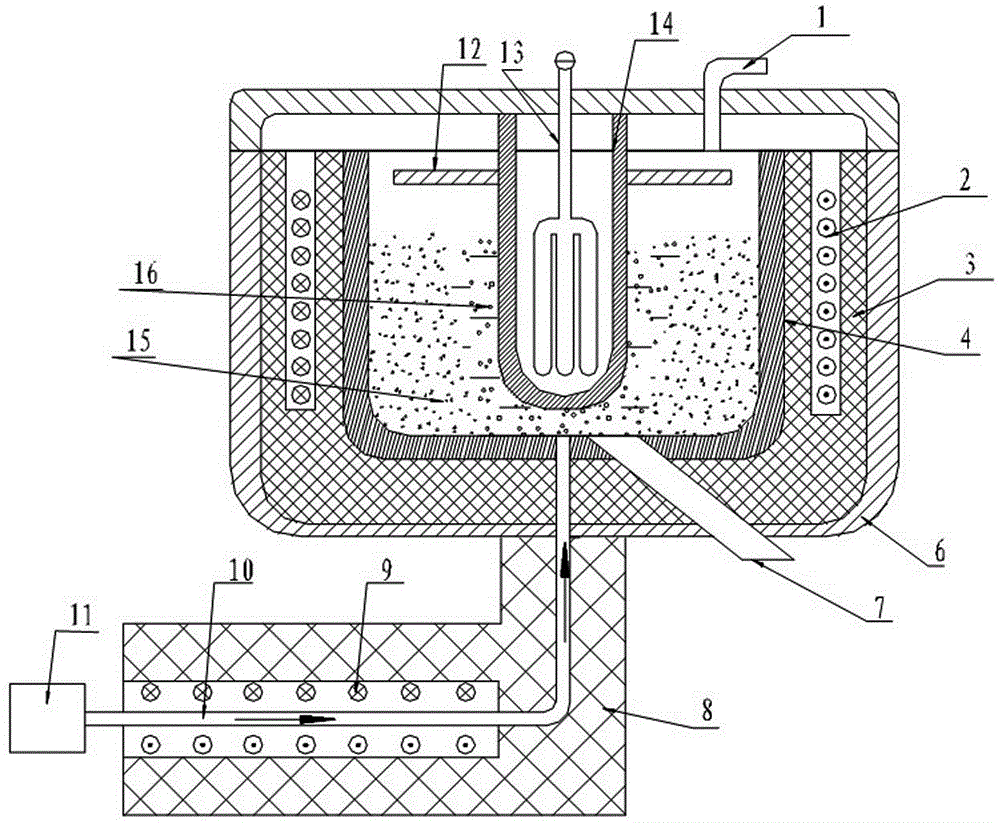

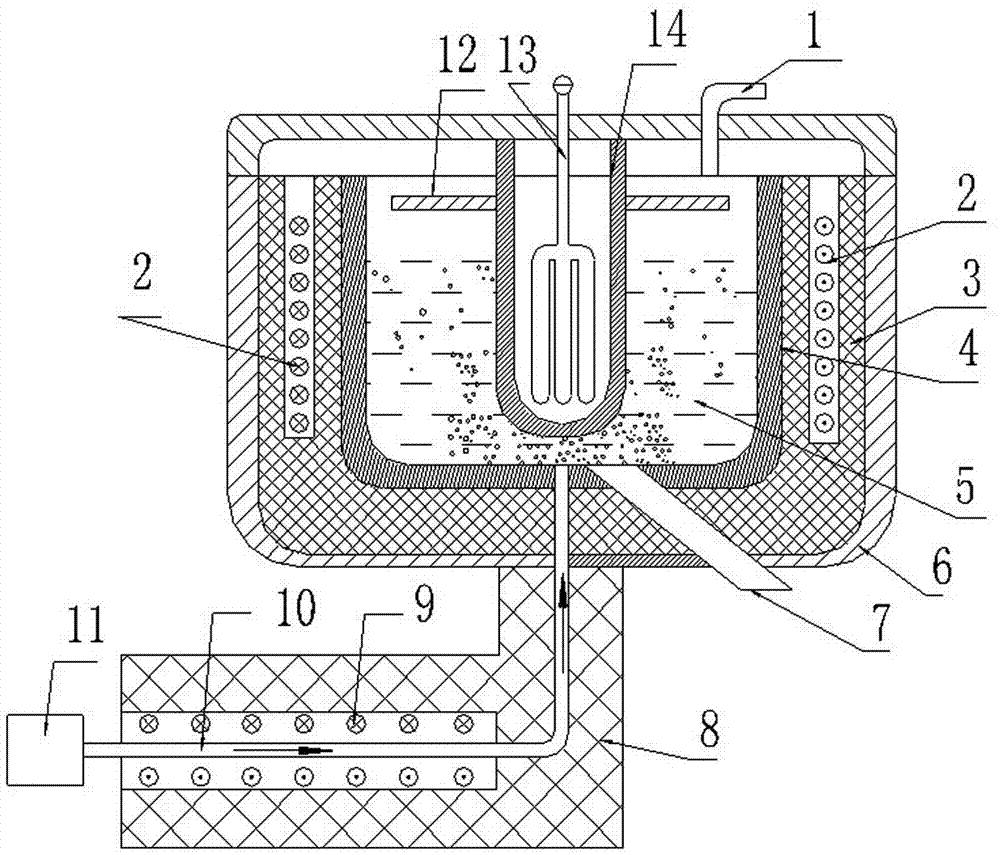

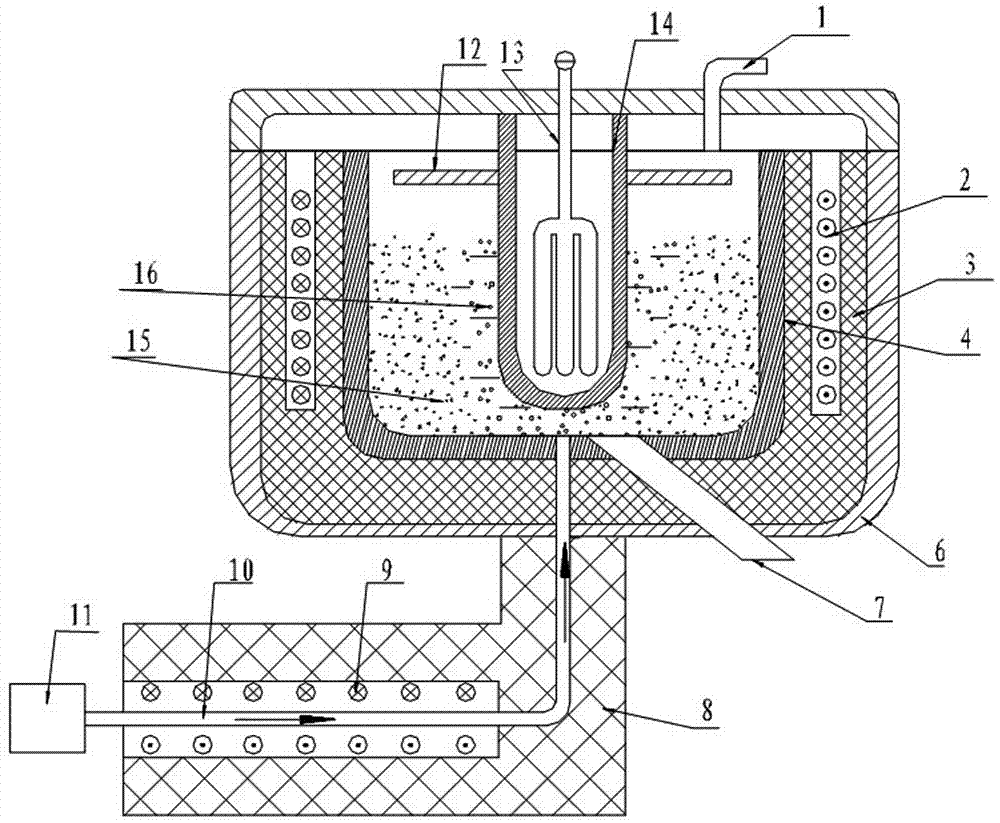

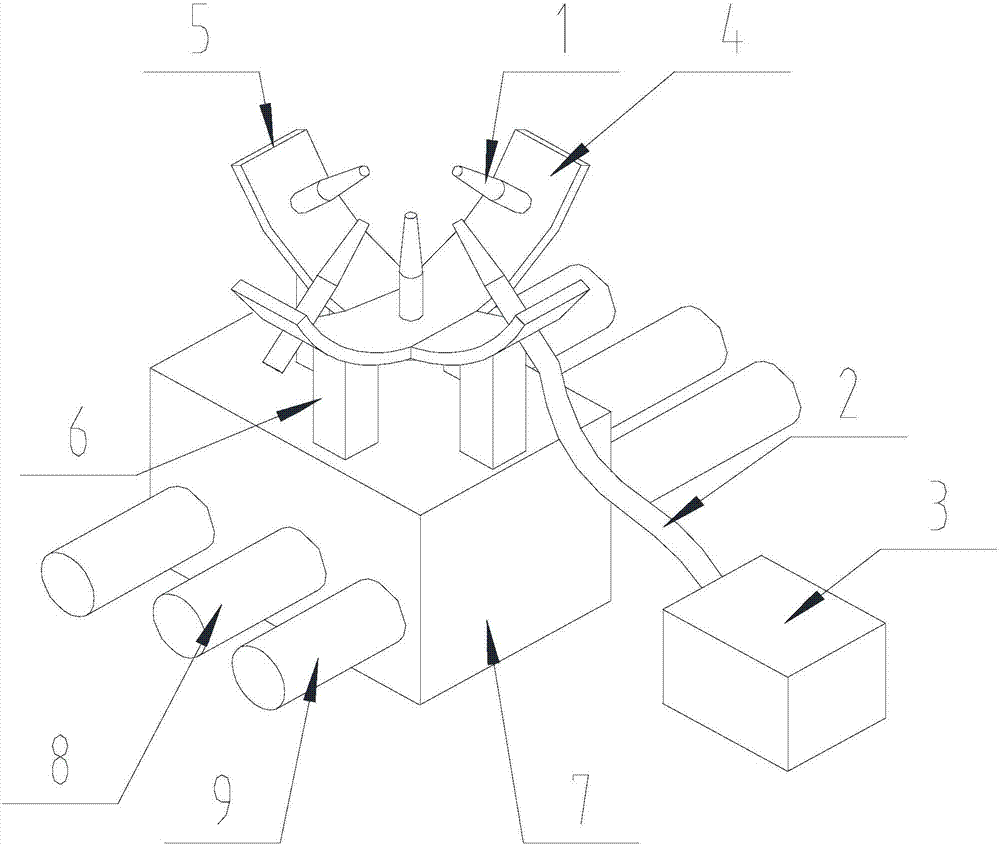

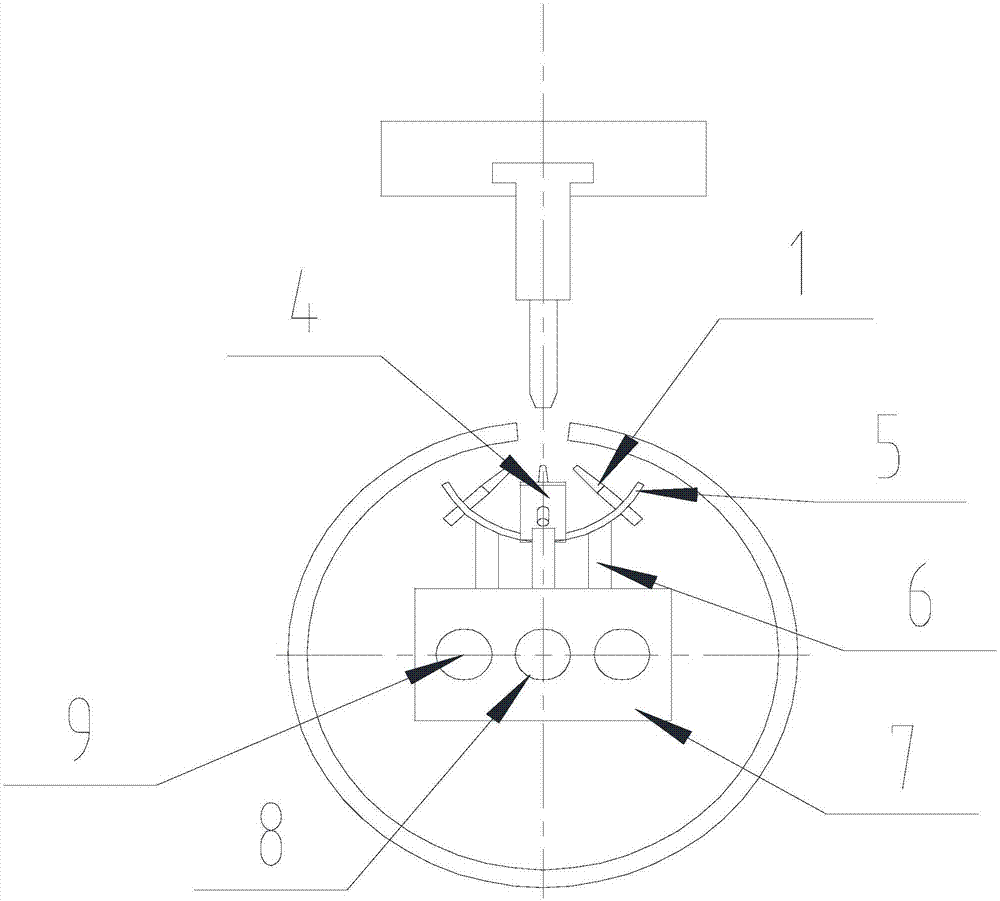

Titanium/steel dissimilar metal plasma shunt melting electrode arc brazing device and method based on pulse coordination control

ActiveCN109226918ALow heat inputImprove melting efficiencyArc welding apparatusWelding/soldering/cutting articlesPeak valueElectric arc

The invention discloses a titanium / steel dissimilar metal plasma shunt melting electrode arc brazing device and method based on pulse coordination control. The device comprises a main welding power supply 1, a shunt power supply 8, a pulse coordination controller 13, a back-pull protection gas cover 2, a plasma shunt melting electrode welding gun 21, a wire feed mechanism 6, a current sensor 19 and the like. In the welding process, a pulse coordination control method is adopted, that is, when the main circuit current is a basic value, the shunt current is also a basic value, and the arc coupling stability in the welding process can be ensured; when the main circuit current is a peak value, the shunt current is also a peak value, the low workpiece heat input during welding can be ensured, and the stable and reliable welding process is realized. Brazed seams are protection by the back-pull protection gas cover in the welding process, and the problems of oxidizing, nitriding and the likein the high-temperature cooling process of the brazed seams are avoided.

Owner:HARBIN ENG UNIV

Nitridation of STI Fill Oxide to Prevent the Loss of STI Fill Oxide During Manufacturing Process

InactiveUS20080090379A1Reduce erosionReduce formationSemiconductor/solid-state device manufacturingHigh concentrationEtching

A method and structure for an improved shallow trench isolation (STI) structure for a semiconductor device. The STI structure incorporates an oxynitride top layer of the STI fill. Optionally, the STI structure incorporates an oxynitride margin of the STI fill adjacent the silicon trench walls. A region of the oxynitride margin near the upper edges of the silicon trench walls includes oxynitride corners that are relatively thicker and contain a higher concentration of nitrogen as compared to the other regions of the oxynitride margin. The oxynitride features limit the STI fill height loss and also reduce the formation of divots in the STI fill below the level of the silicon substrate cause by hydrofluoric acid etching and other fabrication processes. Limiting STI fill height loss and the formation of divots improves the functions of the STI structure. The method of forming the STI structure is particularly compatible with standard semiconductor device fabrication processes, including chemical mechanical polishing (CMP), because the method incorporates the use of a pure silicon dioxide STI fill and plasma and thermal nitridation processes to form the oxynitride top layer and oxynitride margin, including the oxynitride corners, of the STI fill.

Owner:INT BUSINESS MASCH CORP

Annealing technology of silicon steel plate for motor

InactiveCN107119178ADifficult to processStress reliefFurnace typesHeat treatment furnacesSteel platesSilicon

The invention discloses an annealing technology of a silicon steel plate for a motor. After early washing is carried out on the grease of a stamped plate, the stamped plate is conveyed into an annealing oxidizing furnace to carry out annealing treatment. By reasonably controlling annealing time and annealing temperature, the stress of the silicon steel plate is eliminated for restoring the original magnetic performance. Therefore, the magnetic conducting performance of a prepared iron core is improved, the efficiency of the prepared motor is increased, the temperature rise of the motor is reduced, and the cost is saved.

Owner:南通长江电器实业有限公司

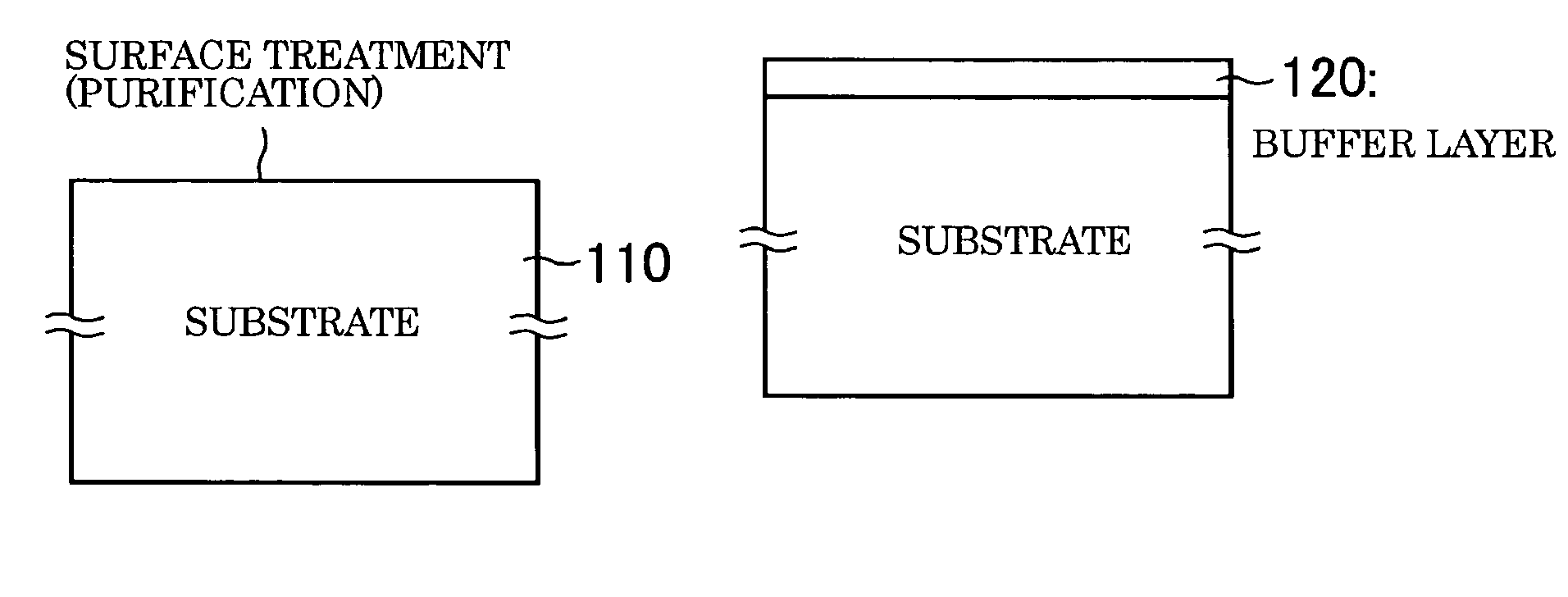

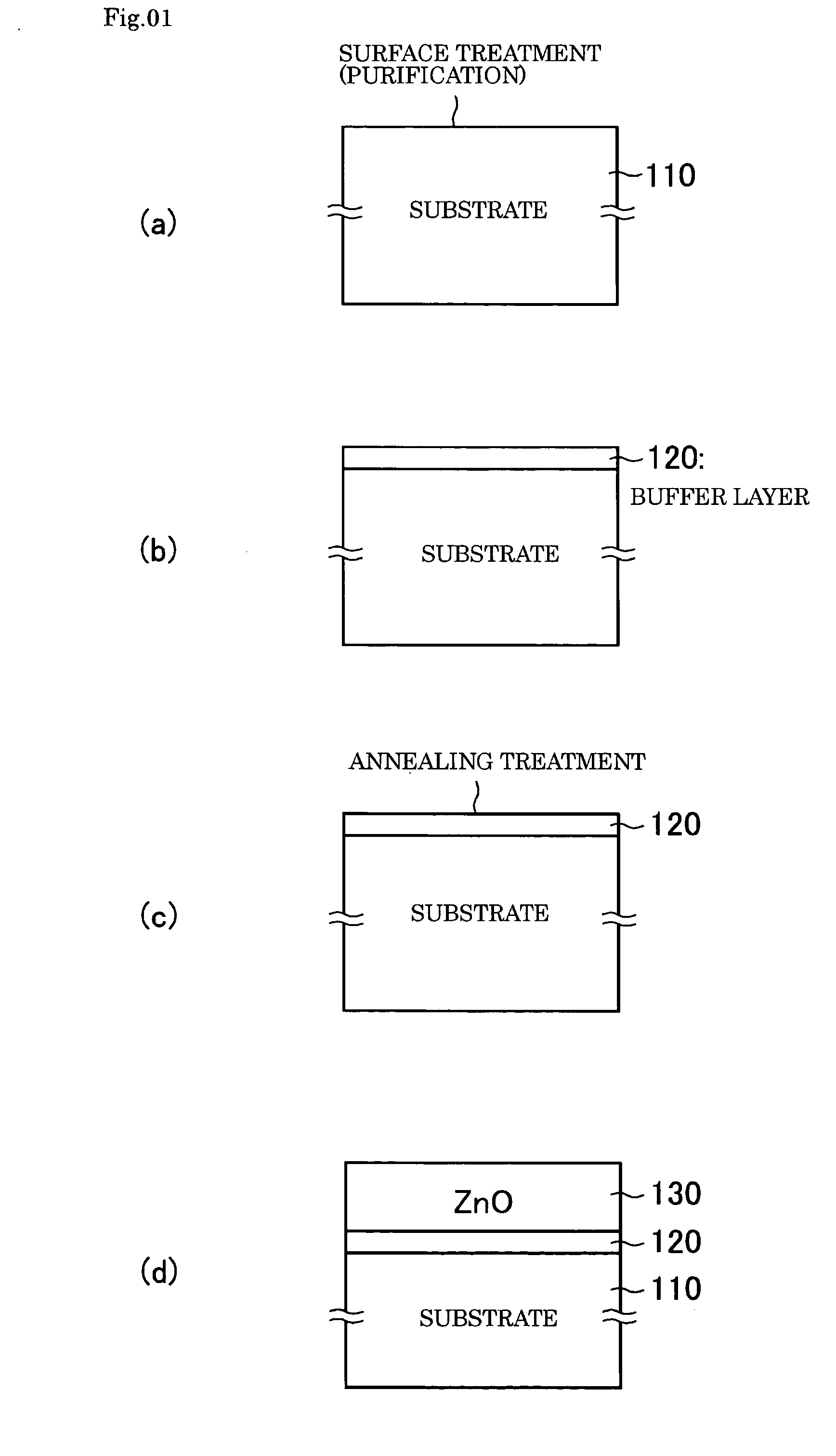

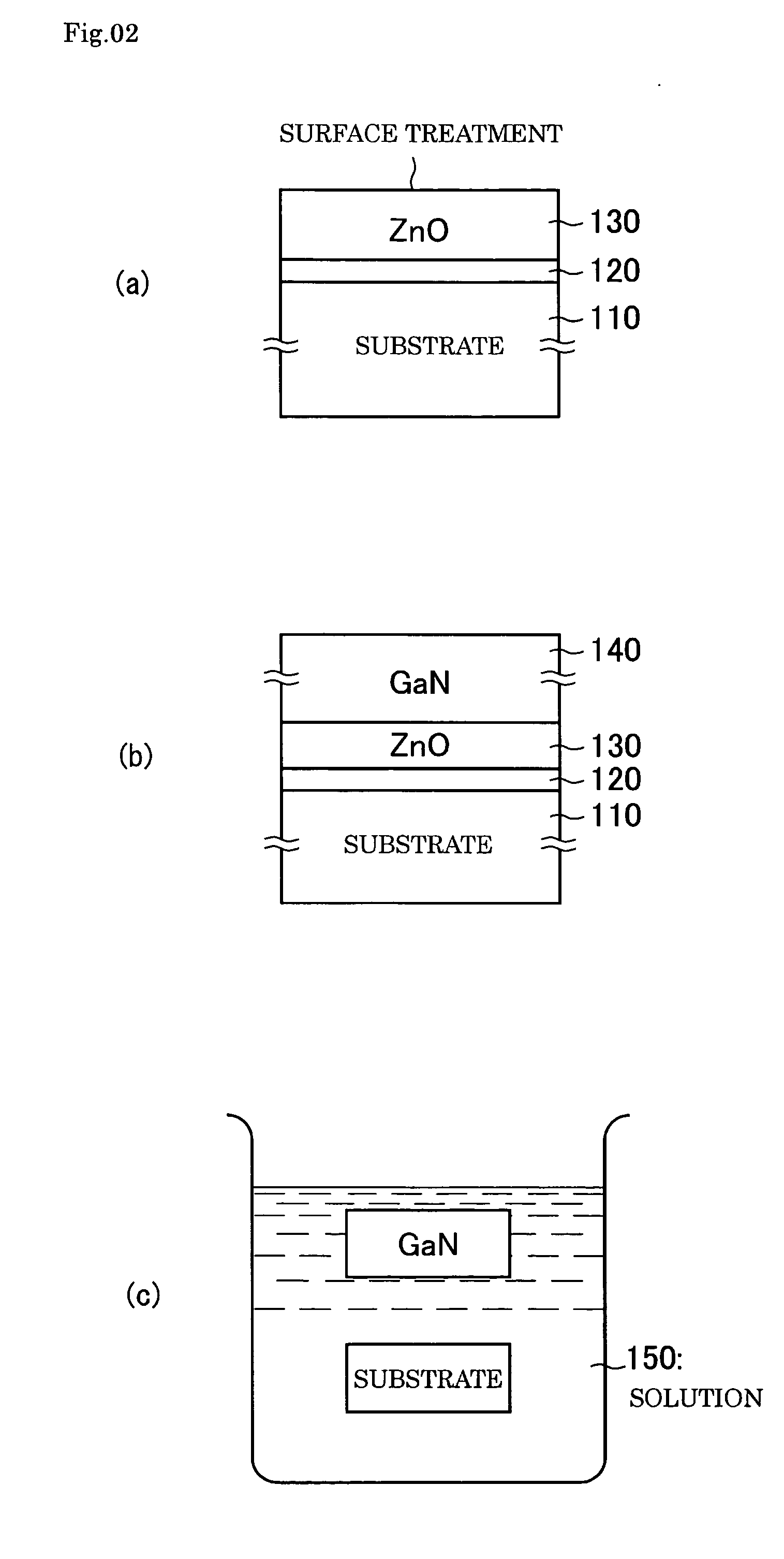

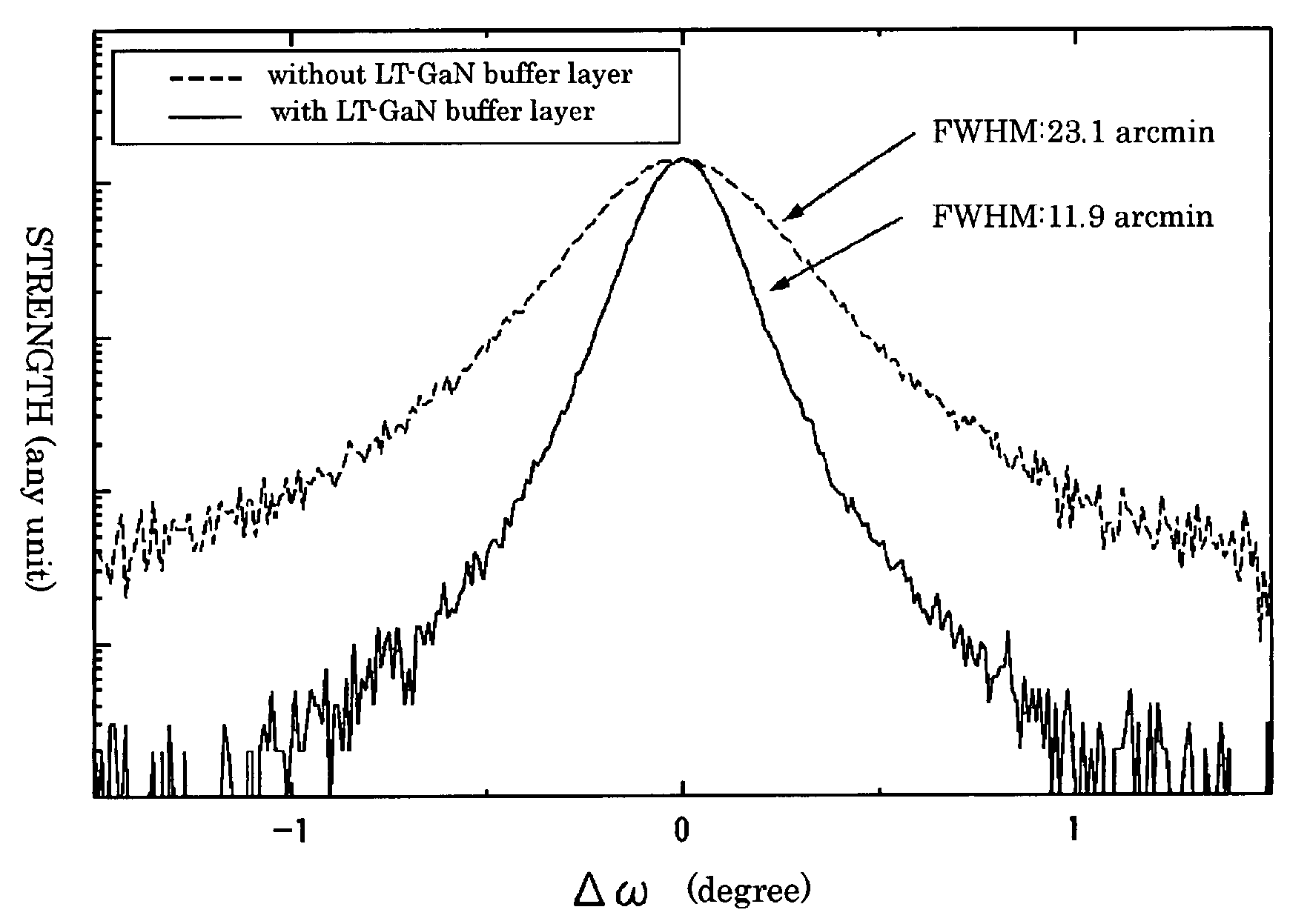

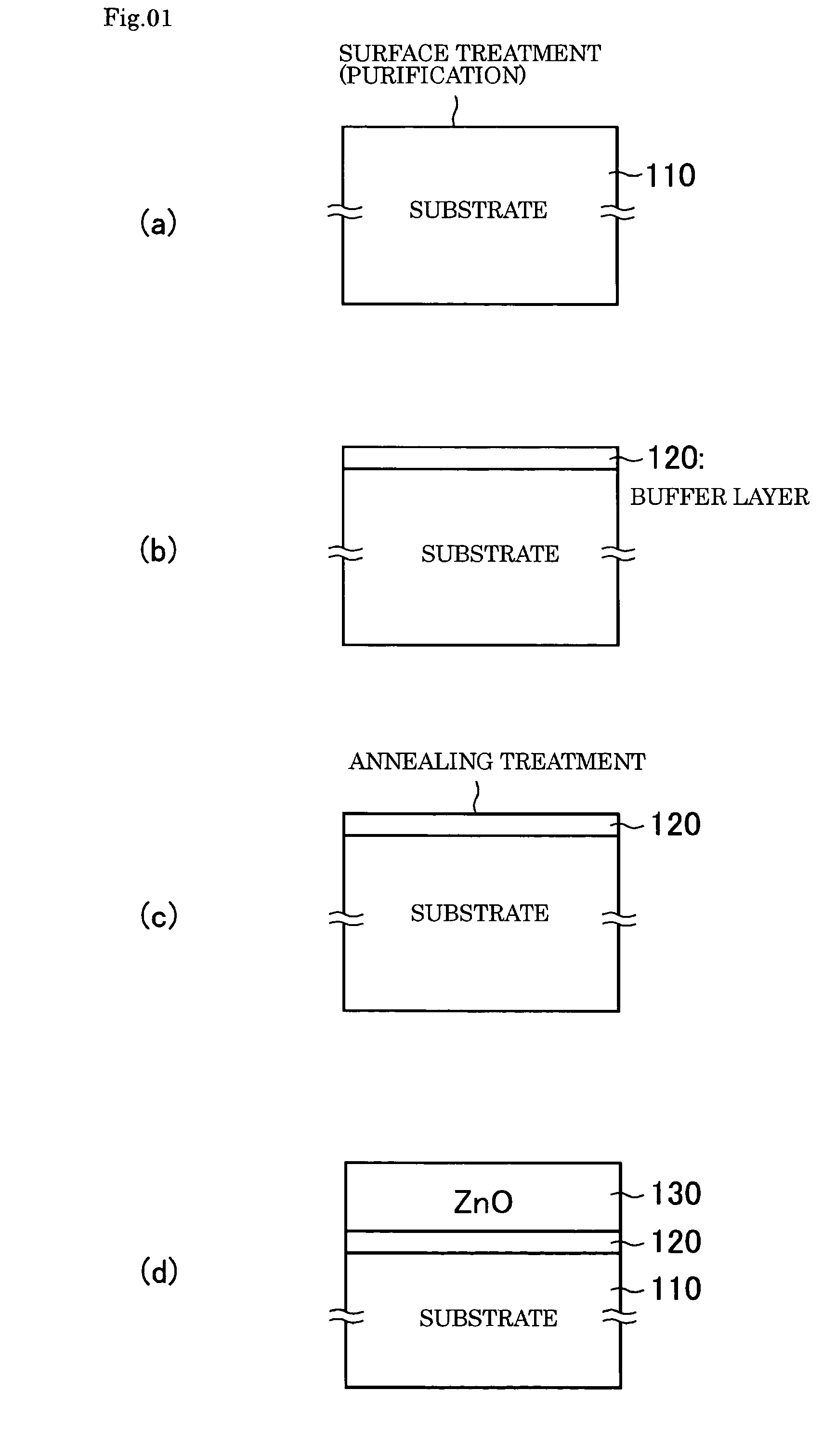

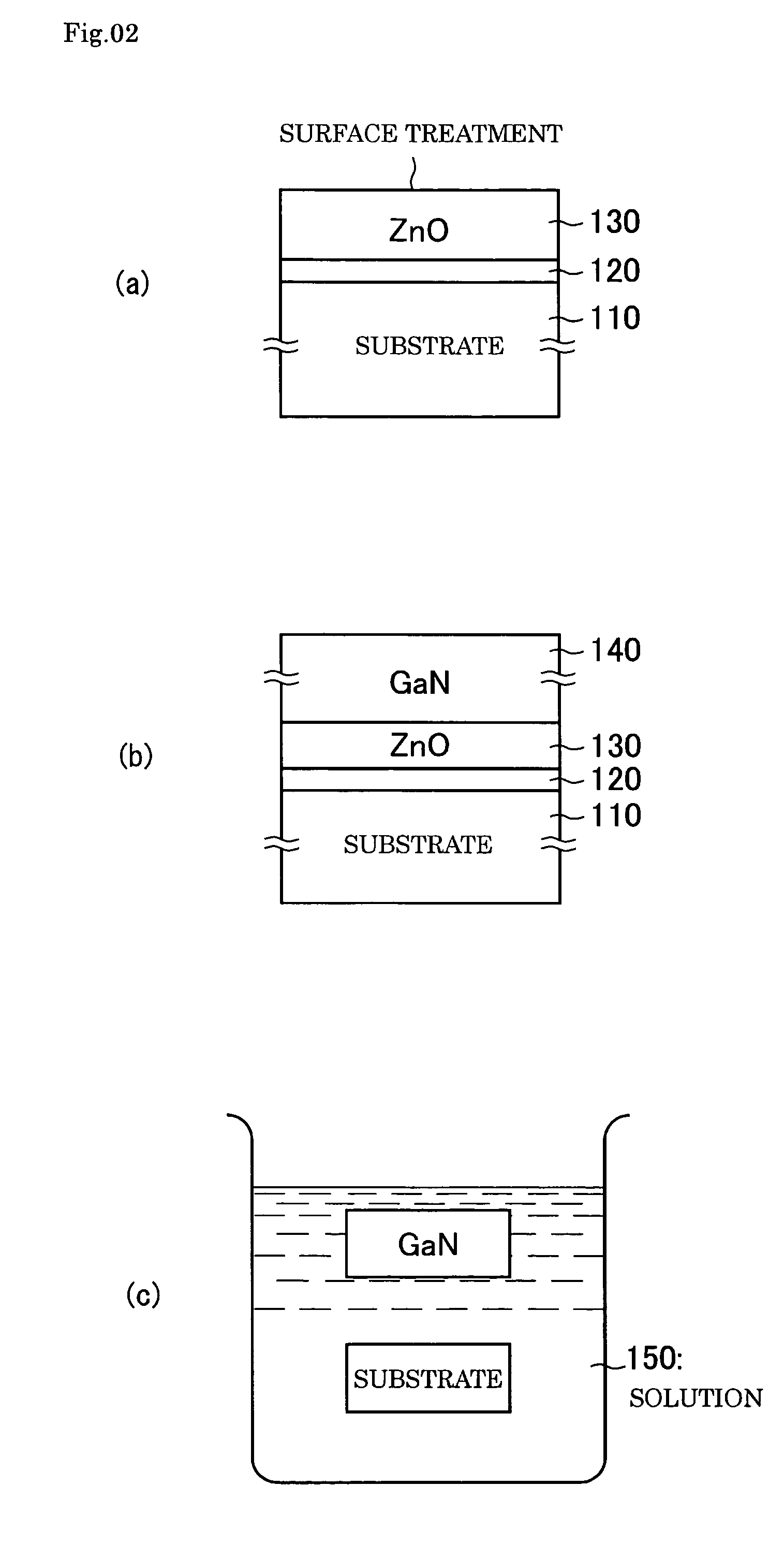

Process for producing gan substrate

InactiveUS20060252164A1Prevent nitridingPolycrystalline material growthAfter-treatment detailsOptoelectronics

Owner:TOHOKU TECHNO ARCH CO LTD

Nitridation of STI fill oxide to prevent the loss of STI fill oxide during manufacturing process

InactiveUS7491964B2Reduce erosionReduce formationTransistorSemiconductor/solid-state device manufacturingHigh concentrationEtching

A method and structure for an improved shallow trench isolation (STI) structure for a semiconductor device. The STI structure incorporates an oxynitride top layer of the STI fill. Optionally, the STI structure incorporates an oxynitride margin of the STI fill adjacent the silicon trench walls. A region of the oxynitride margin near the upper edges of the silicon trench walls includes oxynitride corners that are relatively thicker and contain a higher concentration of nitrogen as compared to the other regions of the oxynitride margin. The oxynitride features limit the STI fill height loss and also reduce the formation of divots in the STI fill below the level of the silicon substrate cause by hydrofluoric acid etching and other fabrication processes. Limiting STI fill height loss and the formation of divots improves the functions of the STI structure. The method of forming the STI structure is particularly compatible with standard semiconductor device fabrication processes, including chemical mechanical polishing (CMP), because the method incorporates the use of a pure silicon dioxide STI fill and plasma and thermal nitridation processes to form the oxynitride top layer and oxynitride margin, including the oxynitride corners, of the STI fill.

Owner:INT BUSINESS MASCH CORP

Surfacing welding strip with excellent heat fatigue resistance

InactiveCN108326467AExcellent resistance to cold and heat fatigueSolve the problem of resurgenceWelding/cutting media/materialsSoldering mediaMolybdenum carbideFerrochrome

The invention discloses a surfacing welding strip with excellent heat fatigue resistance. The surfacing welding strip is composed of a welding core and two layers of coatings, wherein the first layerof coating is fabricated by the following ingredients of , by weight, 18-26 parts of high carbon ferromanganese, 10-14 parts of carbon ferrochrome, 7-9 parts of magnet, 1-3 parts of hydroxyapatite, 2-5 parts of strontianite and 3-6 parts of aedelforsite, and the second layer of coating is fabricated by the following ingredients of , by weight, 15-20 parts of titanium oxide, 10-13 parts of ferrotitanium, 2-4 parts of silicon nitride, 5-7 parts of molybdenum carbide and 1-3 parts of tungsten disulfide nanotubes. By means of the surfacing welding strip with the excellent heat fatigue resistance,the fabricated welding strip can work in a high-temperature corrosion or high-temperature wear medium for a long time and can maintain excellent cold and heat fatigue resistance and good high-temperature performance of high-temperature oxidation resistance, high-temperature corrosion resistance, high-temperature tempering stability, red hardness and the like, in the working process, electric arc burns stably, arc breaking is not prone to appear, almost no slag is remained on the surface of weld metal, less dust and smoke are generated, and the surfacing welding strip with the excellent heat fatigue resistance has wide applicability.

Owner:安徽省明升机械科技有限公司

Anti-nitridation process for copper-tin composite plating

The invention discloses an anti-nitridation process for copper-tin composite plating, which comprises the following steps: deoiling and cleaning a workpiece, and then performing weak corrosion treatment on the workpiece with sulfuric acid; performing anodic cleaning on the workpiece, wherein the workpiece subjected to anodic cleaning needs to be taken out of the tank while electrified; performing nickel preplating: keeping the workpiece non-electrified and placing the workpiece in an electroplating solution for 2-4 minutes before nickel preplating, then preplating nickel for 1 mu m, and plating dark nickel for 1-2 mu m; performing activating treatment on the workpiece with sulfuric acid; and performing copper cyanideless electroplating, plating dark tin on the surface of the copper-electroplated layer of the workpiece, and finally performing stabilizing treatment. According to the electroplating process disclosed by the invention, the workpiece can similarly achieve the purpose of preventing nitridation, carburization and cyanogen infiltration in case of a thinner copper-plated layer, thus reducing the thickness of the copper-plated layer, reducing the copper consumption, shortening the electroplating time and improving the electroplating efficiency.

Owner:GUIZHOU HONGLIN MACHINERY

Process for producing GaN substrate

InactiveUS7479188B2Prevent nitridingPolycrystalline material growthAfter-treatment detailsOptoelectronicsMaterials science

Owner:TOHOKU TECHNO ARCH CO LTD

Nitridation of STI fill oxide to prevent the loss of STI fill oxide during manufacturing process

InactiveUS7491563B2Reduce erosionReduce formationSemiconductor/solid-state device manufacturingHigh concentrationEtching

Owner:INT BUSINESS MASCH CORP

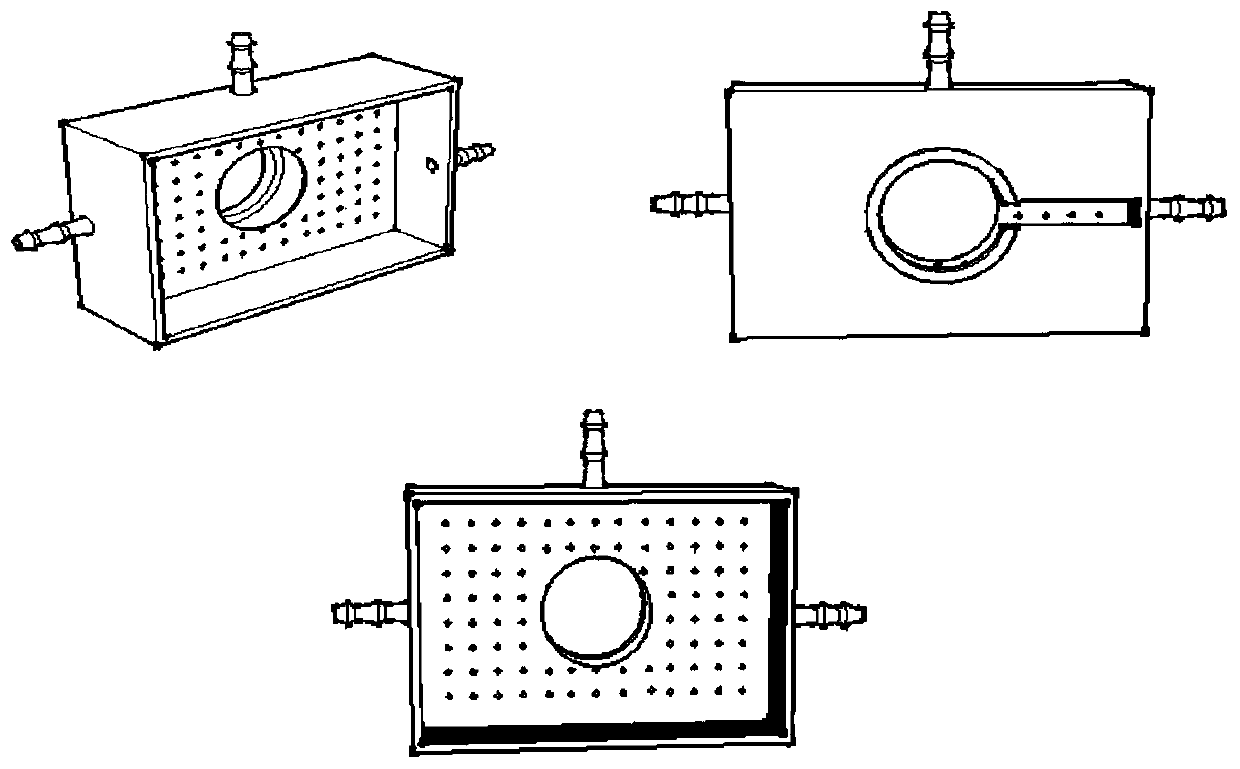

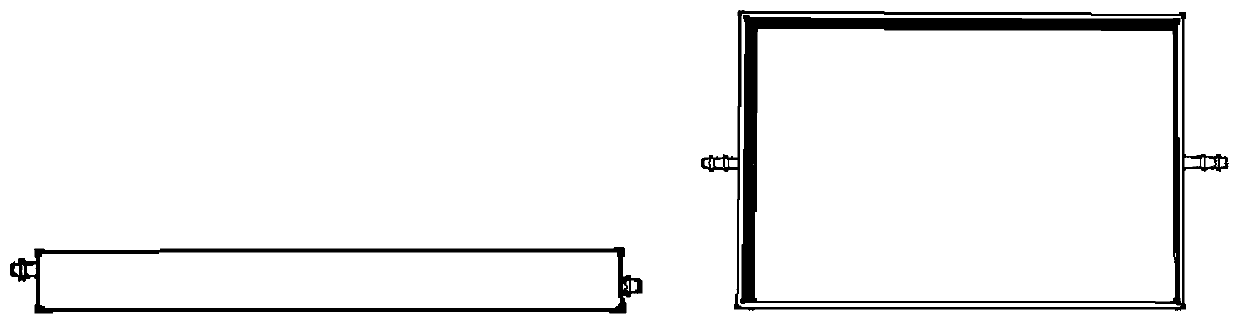

Titanium purification device and use method

The invention discloses a titanium purification device. The titanium purification device comprises a purification bag, a high-pressure and high-temperature inert gas device, a heating device and an exhaust duct, wherein the purification bag is of a closed tank structure, a crucible is arranged in the purification bag, a gap between the crucible and the purification bag is filled with a thermal insulation material, and a cooling device is embedded in the thermal insulation material; an outlet of the high-pressure and high-temperature inert gas device penetrates through the bottom of the purification bag and the thermal insulation material to be communicated with the bottom of the crucible, and a liquid outlet pipe extending out of the purification bag is arranged at the bottom of the crucible; the heating device comprises a middle heater, the upper end of the middle heater is fixed at the top of the purification bag, and the lower end is arranged in a cavity of the crucible; and the exhaust duct is arranged at the top of the purification bag. According to the titanium purification device, preheated inert gas blown from the bottom has a stirring effect on a titanium solution, enabling the surface titanium solution and inner titanium solution to have mass exchange continuously, so that impurities in the titanium solution rise to the liquid level, and volatile impurities are removed.

Owner:YIXING YUYUAN ENERGY EQUIP TECH DEV

A copper-tin composite plating anti-nitridation process

The invention discloses an anti-nitridation process for copper-tin composite plating, which comprises the following steps: deoiling and cleaning a workpiece, and then performing weak corrosion treatment on the workpiece with sulfuric acid; performing anodic cleaning on the workpiece, wherein the workpiece subjected to anodic cleaning needs to be taken out of the tank while electrified; performing nickel preplating: keeping the workpiece non-electrified and placing the workpiece in an electroplating solution for 2-4 minutes before nickel preplating, then preplating nickel for 1 mu m, and plating dark nickel for 1-2 mu m; performing activating treatment on the workpiece with sulfuric acid; and performing copper cyanideless electroplating, plating dark tin on the surface of the copper-electroplated layer of the workpiece, and finally performing stabilizing treatment. According to the electroplating process disclosed by the invention, the workpiece can similarly achieve the purpose of preventing nitridation, carburization and cyanogen infiltration in case of a thinner copper-plated layer, thus reducing the thickness of the copper-plated layer, reducing the copper consumption, shortening the electroplating time and improving the electroplating efficiency.

Titanium purification device and method of use

The invention discloses a titanium purification device. The titanium purification device comprises a purification bag, a high-pressure and high-temperature inert gas device, a heating device and an exhaust duct, wherein the purification bag is of a closed tank structure, a crucible is arranged in the purification bag, a gap between the crucible and the purification bag is filled with a thermal insulation material, and a cooling device is embedded in the thermal insulation material; an outlet of the high-pressure and high-temperature inert gas device penetrates through the bottom of the purification bag and the thermal insulation material to be communicated with the bottom of the crucible, and a liquid outlet pipe extending out of the purification bag is arranged at the bottom of the crucible; the heating device comprises a middle heater, the upper end of the middle heater is fixed at the top of the purification bag, and the lower end is arranged in a cavity of the crucible; and the exhaust duct is arranged at the top of the purification bag. According to the titanium purification device, preheated inert gas blown from the bottom has a stirring effect on a titanium solution, enabling the surface titanium solution and inner titanium solution to have mass exchange continuously, so that impurities in the titanium solution rise to the liquid level, and volatile impurities are removed.

Owner:YIXING YUYUAN ENERGY EQUIP TECH DEV

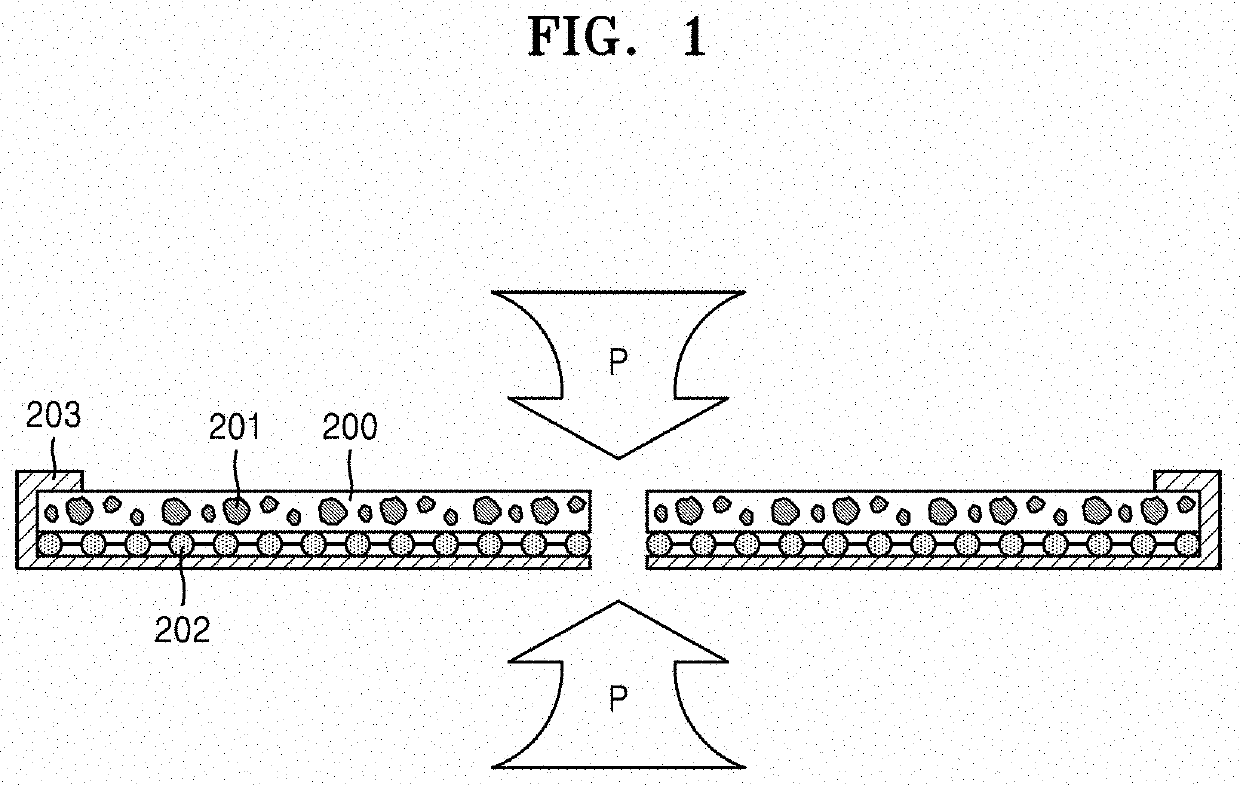

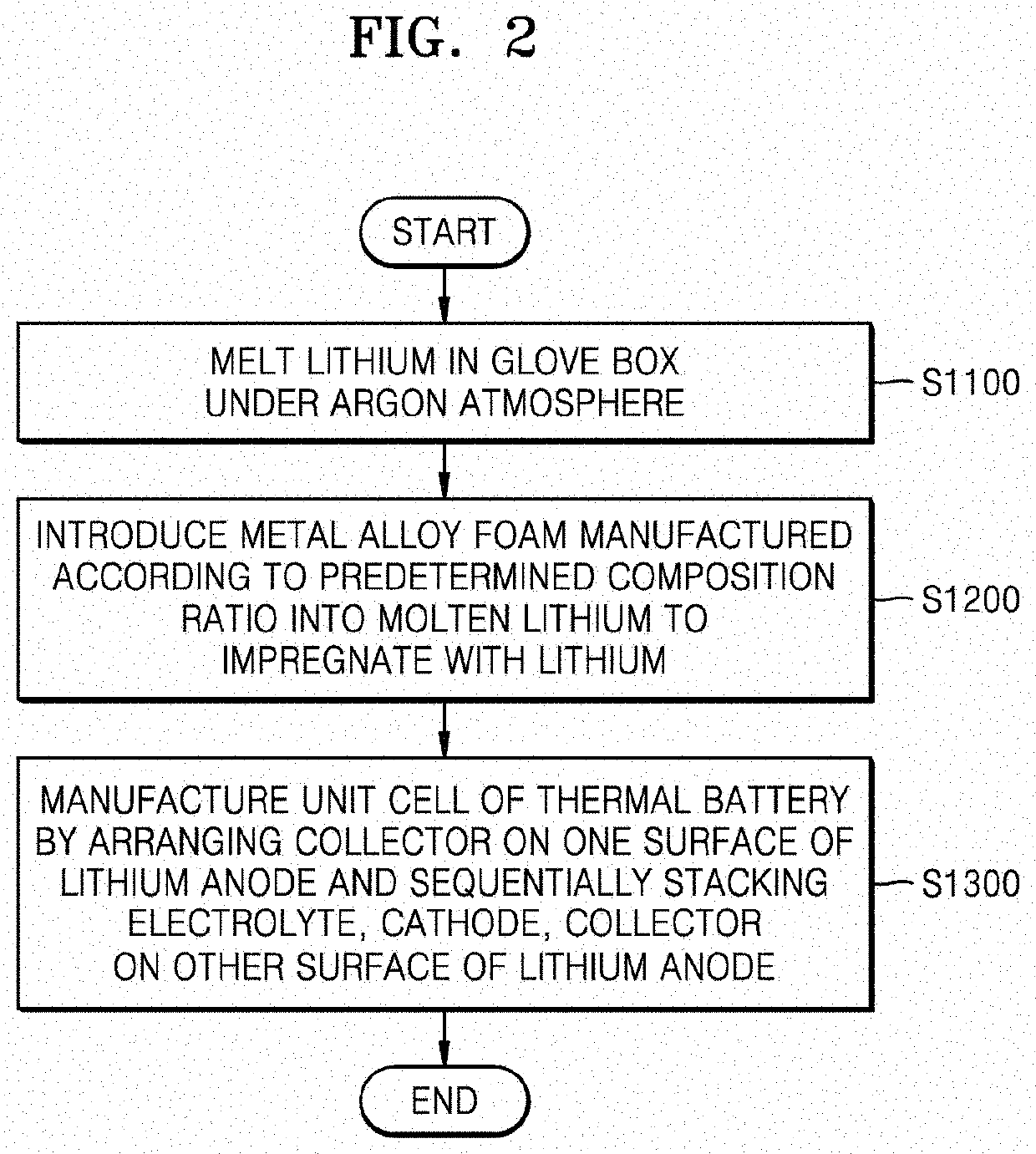

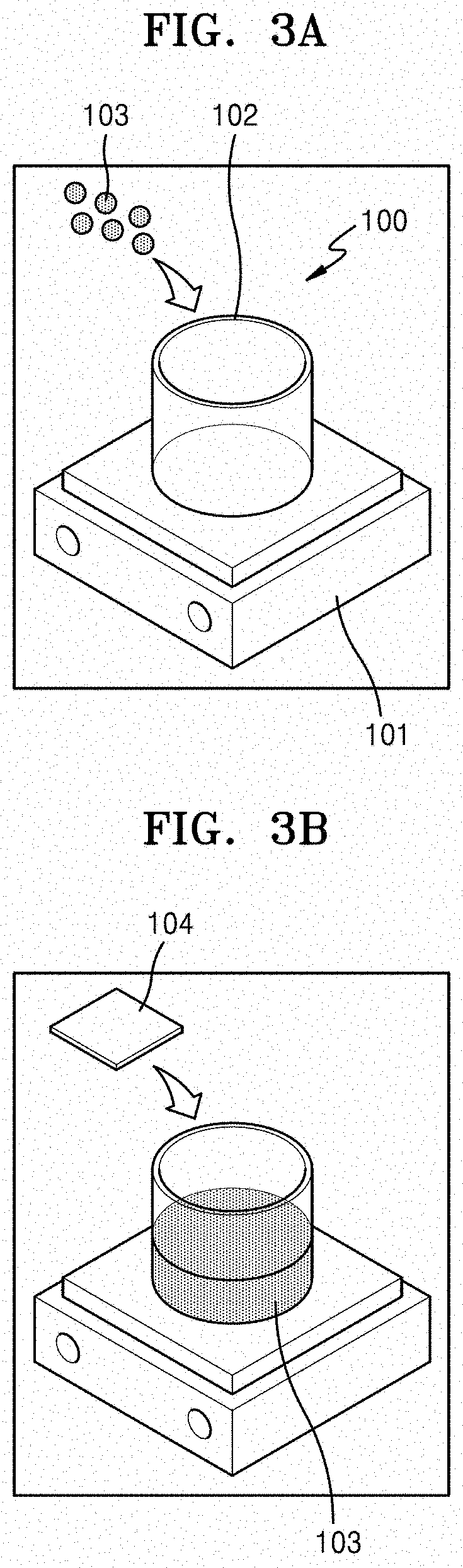

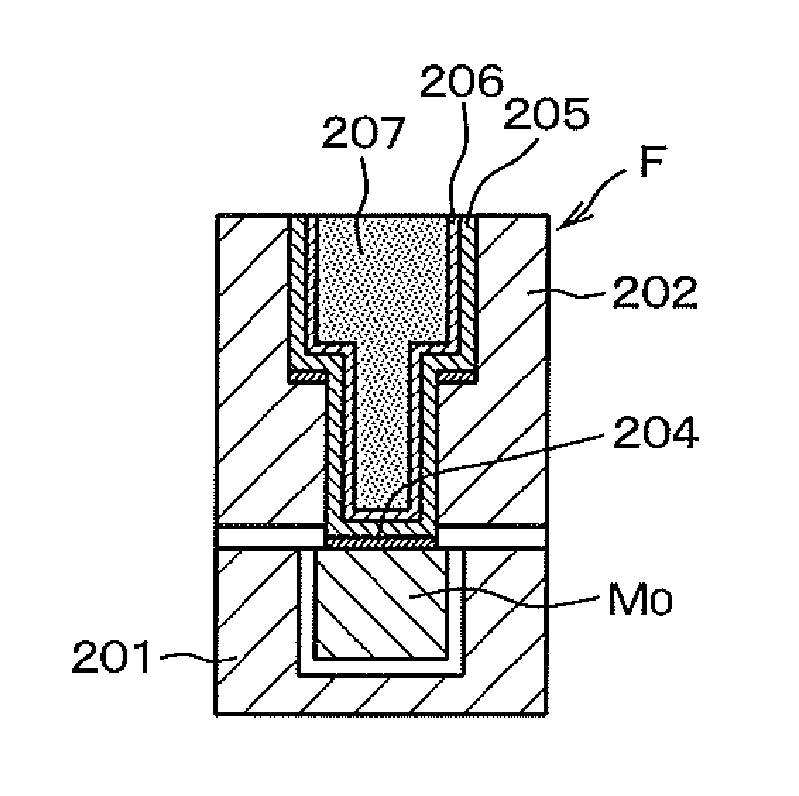

Anode for thermal battery, apparatus for manufacturing the anode for thermal battery, and method of manufacturing the anode for thermal battery

ActiveUS20210126239A1Excellent impregnationLow costDeferred-action cellsPrimary cell electrodesMetallurgyMetal alloy

A lithium anode of a thermal battery may include a metal alloy foam in which a plurality of pores is formed and including nickel (Ni), iron (Fe), chromium (Cr), and aluminum (Al) mixed in a predetermined composition ratio, and lithium impregnated into the metal alloy foam in a molten state and accommodated in the pores, wherein the chromium in the composition ratio may facilitate the impregnation of the lithium into the pores and reduce the reactivity of the metal alloy foam to the lithium at an operating temperature of the thermal battery, and the aluminum in the composition ratio may facilitate the impregnation of the lithium into the pores and prevent the lithium from penetrating into a surface of the metal alloy foam.

Owner:AGENCY FOR DEFENSE DEV

Copper wiring forming method, film forming system, and storage medium

ActiveUS9425093B2Reduce resistanceVolume maximizationSemiconductor/solid-state device detailsSolid-state devicesCopper-wiringMaterials science

A Cu wiring forming method of forming Cu wiring that is to be arranged in contact with tungsten wiring, by filling Cu into a recess formed in a substrate, includes: removing a tungsten oxide formed on a surface of the tungsten wiring; forming a nitriding preventing film at least on the surface of the tungsten wiring in the recess; forming a barrier film that prevents diffusion of Cu, on a surface in the recess from above the nitriding preventing film; forming a liner film on the barrier film; and filling a Cu film on the liner film.

Owner:TOKYO ELECTRON LTD

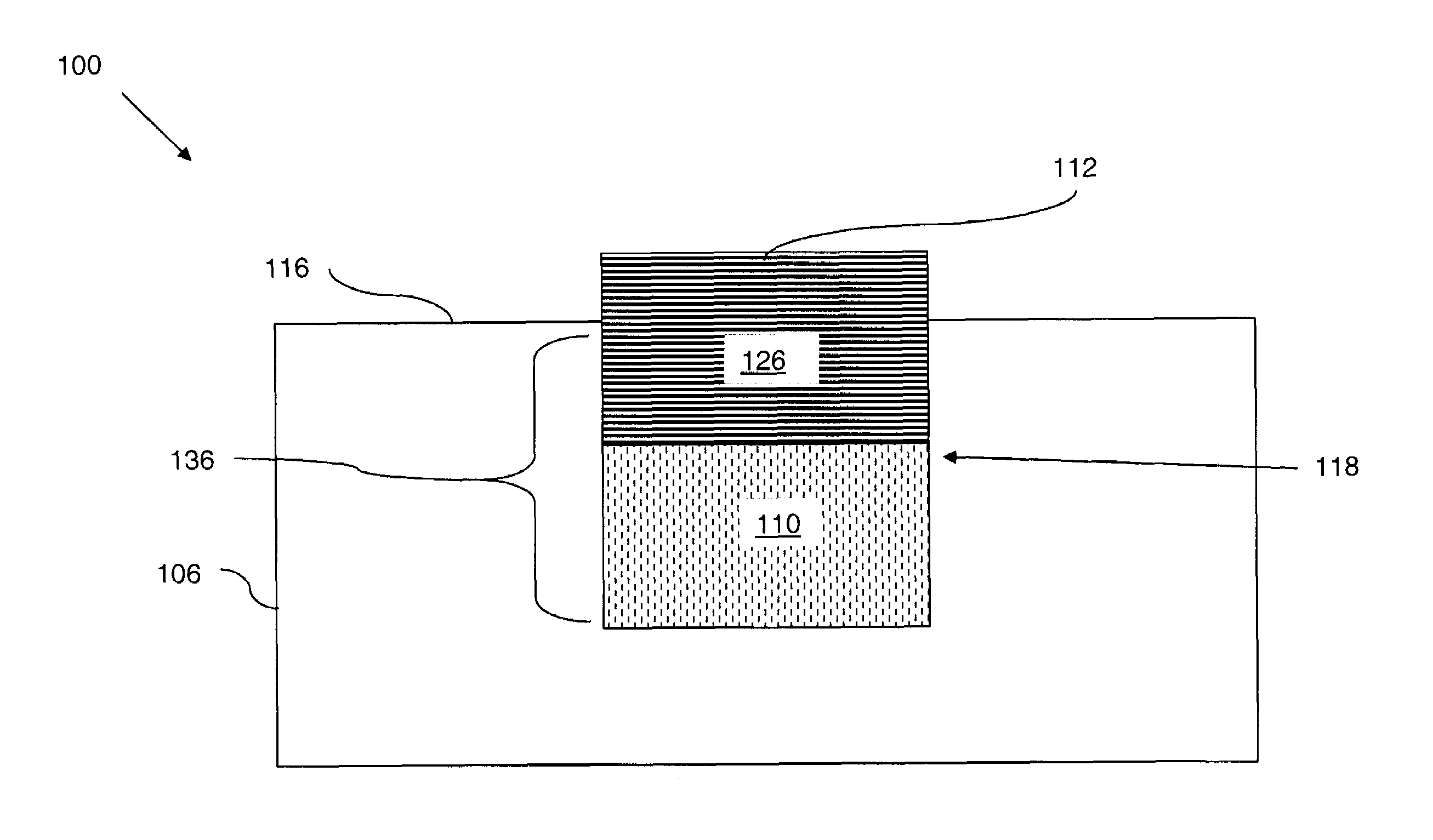

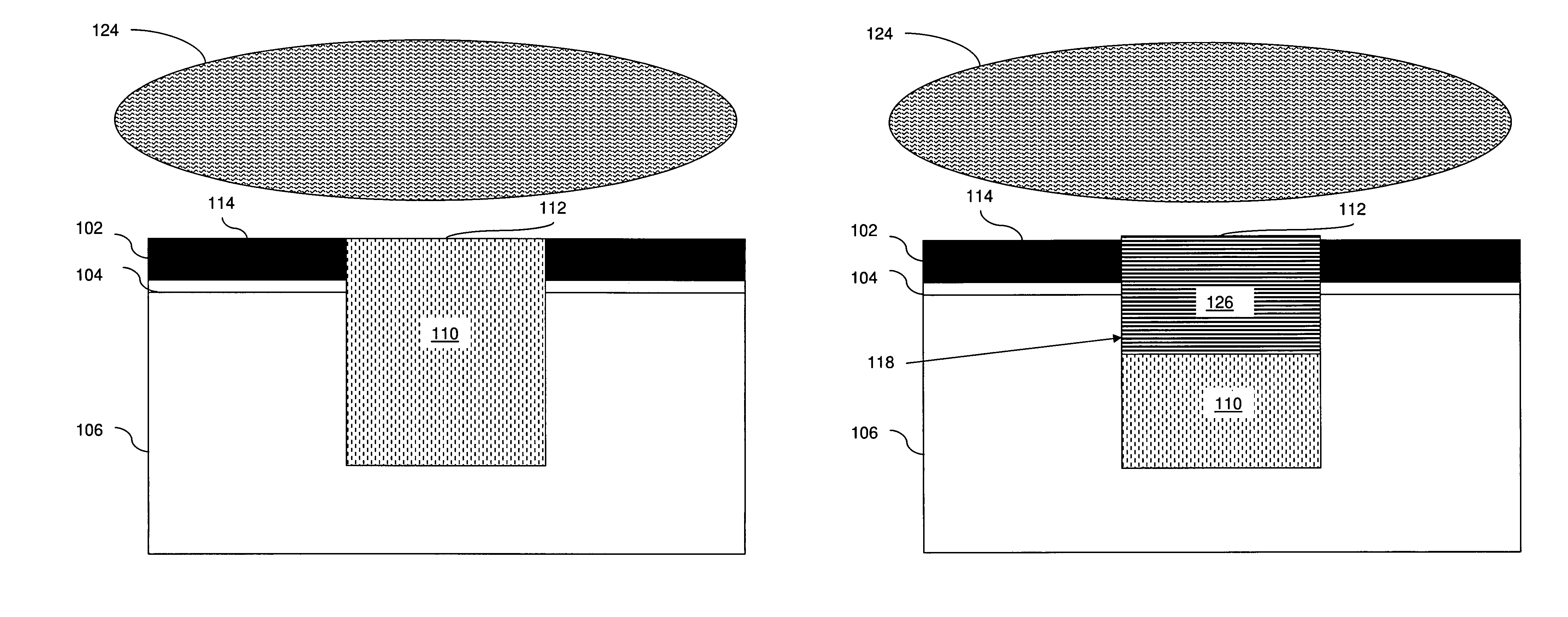

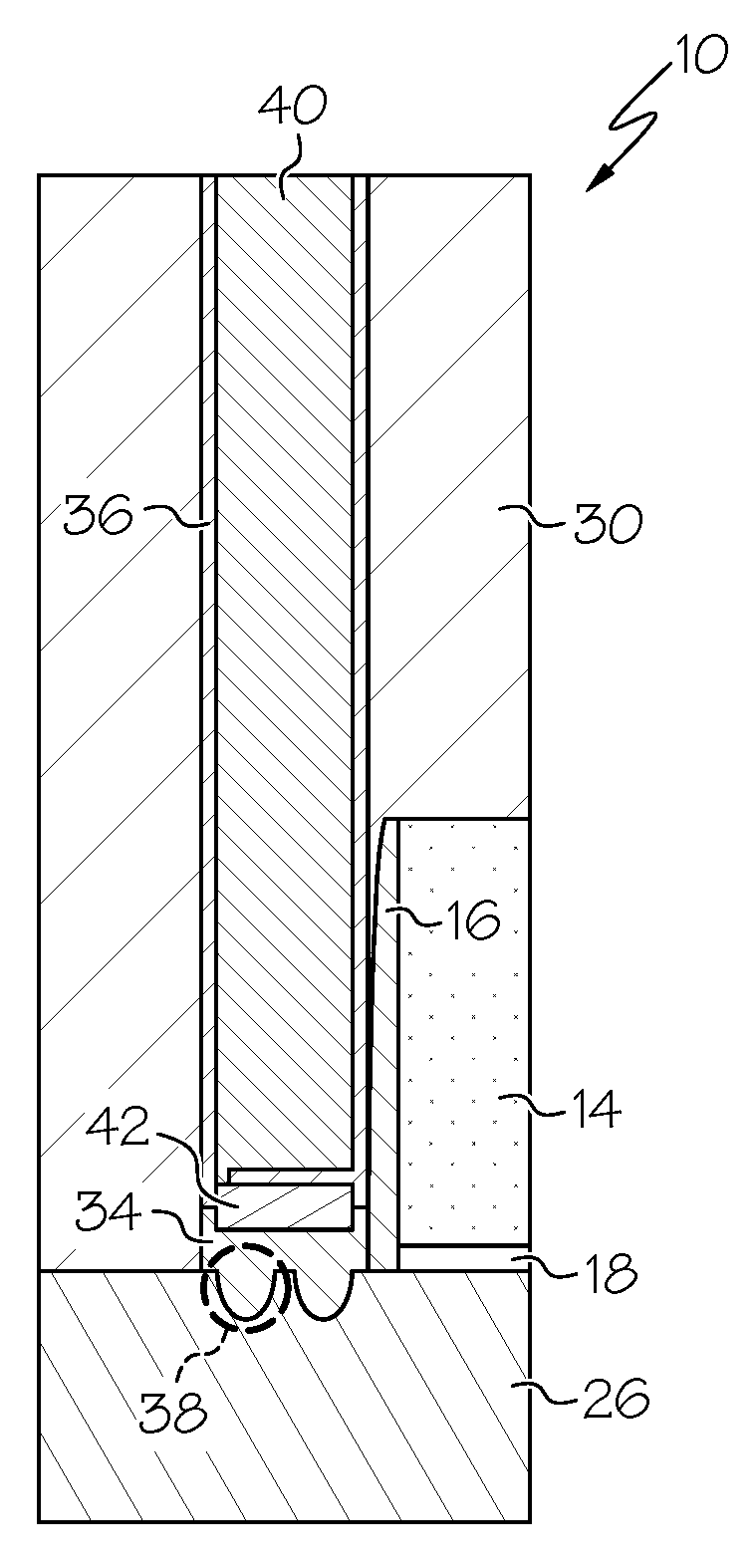

Titanium silicide formation in a narrow source-drain contact

ActiveUS20170372949A1Prevent nitridingSemiconductor/solid-state device detailsSolid-state devicesDevice materialTitanium nitride

Aspects of the present invention relate to approaches for forming a narrow source-drain contact in a semiconductor device. A contact trench can be etched to a source-drain region of the semiconductor device. A titanium liner can be deposited in this contact trench such that it covers substantially an entirety of the bottom and walls of the contact trench. An x-metal layer can be deposited over the titanium liner on the bottom of the contact trench. A titanium nitride liner can then be formed on the walls of the contact trench. The x-metal layer prevents the nitriding of the titanium liner on the bottom of the contact trench during the formation of the nitride liner.

Owner:GLOBALFOUNDRIES U S INC

Deep level ion nitriding process for engine cylinder bushes

ActiveCN102888582BExtended service lifeHigh surface hardnessSolid state diffusion coatingPower flowElectrical conductor

The invention discloses a deep level nitriding process for engine cylinder bushes, comprising the procedures of cleaning, charging, ion nitriding and tapping, wherein in the charging procedure, a bottom supporting disk is supported on a cathode disc by using a conductor column, cylinder bushes are uniformly arranged on the bottom supporting disk, a top plate is arranged on the cylinder bushes, and through holes are arranged on the top plate and the bottom supporting disk corresponding to the positions of the cylinder bushes; and in the ion nitriding procedure, arc light starts when the vacuum degree in a furnace reaches 50Pa below and the voltage is set at 650V, then the voltage and the duty cycle are sequentially increased, ammonia gas is fed into the furnace after the voltage is adjusted to 700V and the arc light frequency is reduced, the voltage in the furnace is adjusted to 750V when the arc light basically disappears, the glow is stable and the flow of the ammonia gas is not increased, heat preservation is carried out at 520 DEG C for 15h and 540 DEG C for 25h, the flow of the ammonia gas is 0.5-0.8L / min and the vacuum degree is 500-800Pa, and the temperature of the cylinder bushes are gradually reduced under the glow state, and furnace shutdown, gas cutoff and cooling are carried out after the temperature is reduced to 300 DEG C below. Based on the ion nitriding process disclosed by the invention, the nitriding speed is high, the diffusion layer is deep, and the technical requirements of engine cylinder bushes are met.

Owner:HEBEI HUABEI DIESEL ENGINE

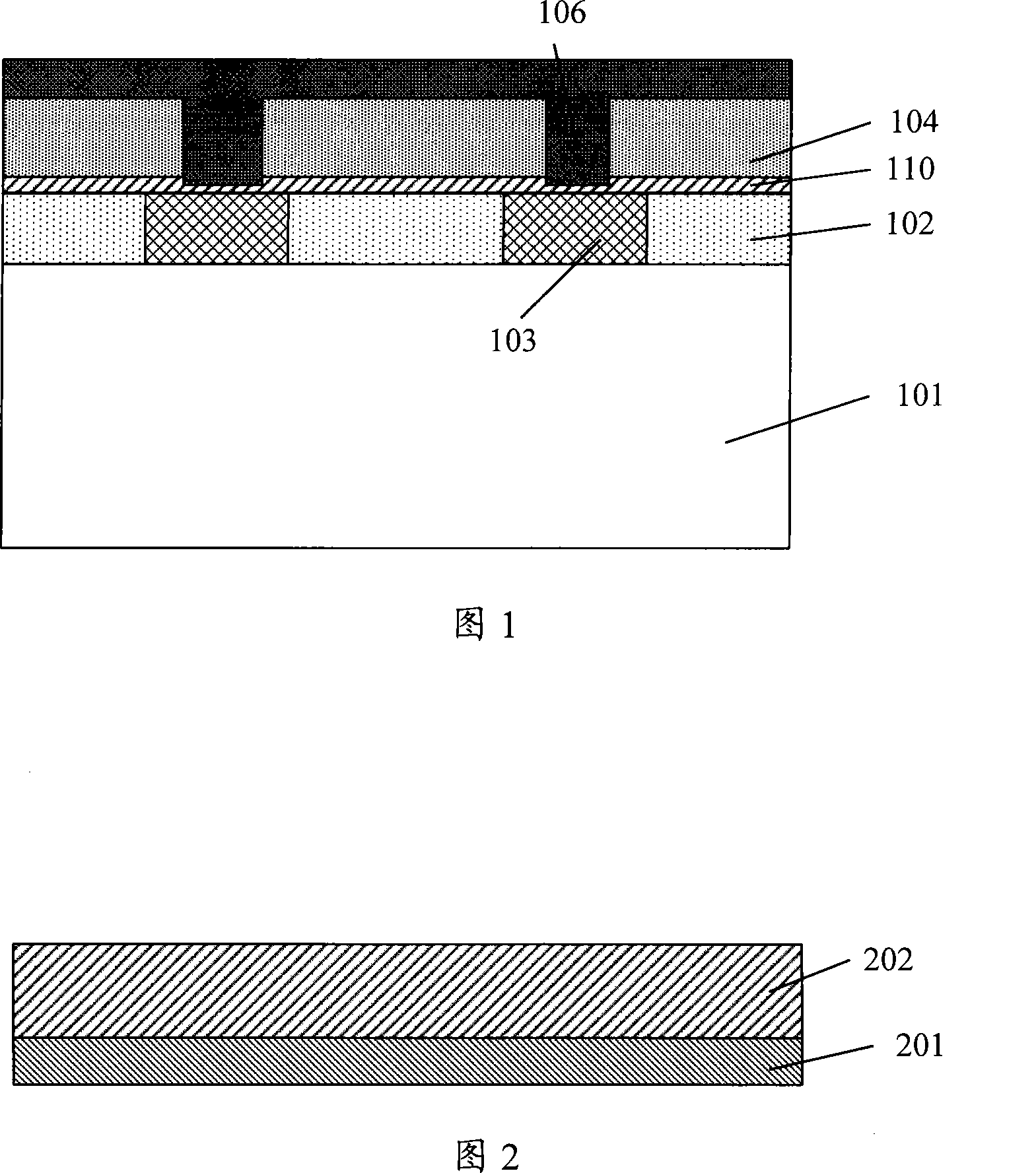

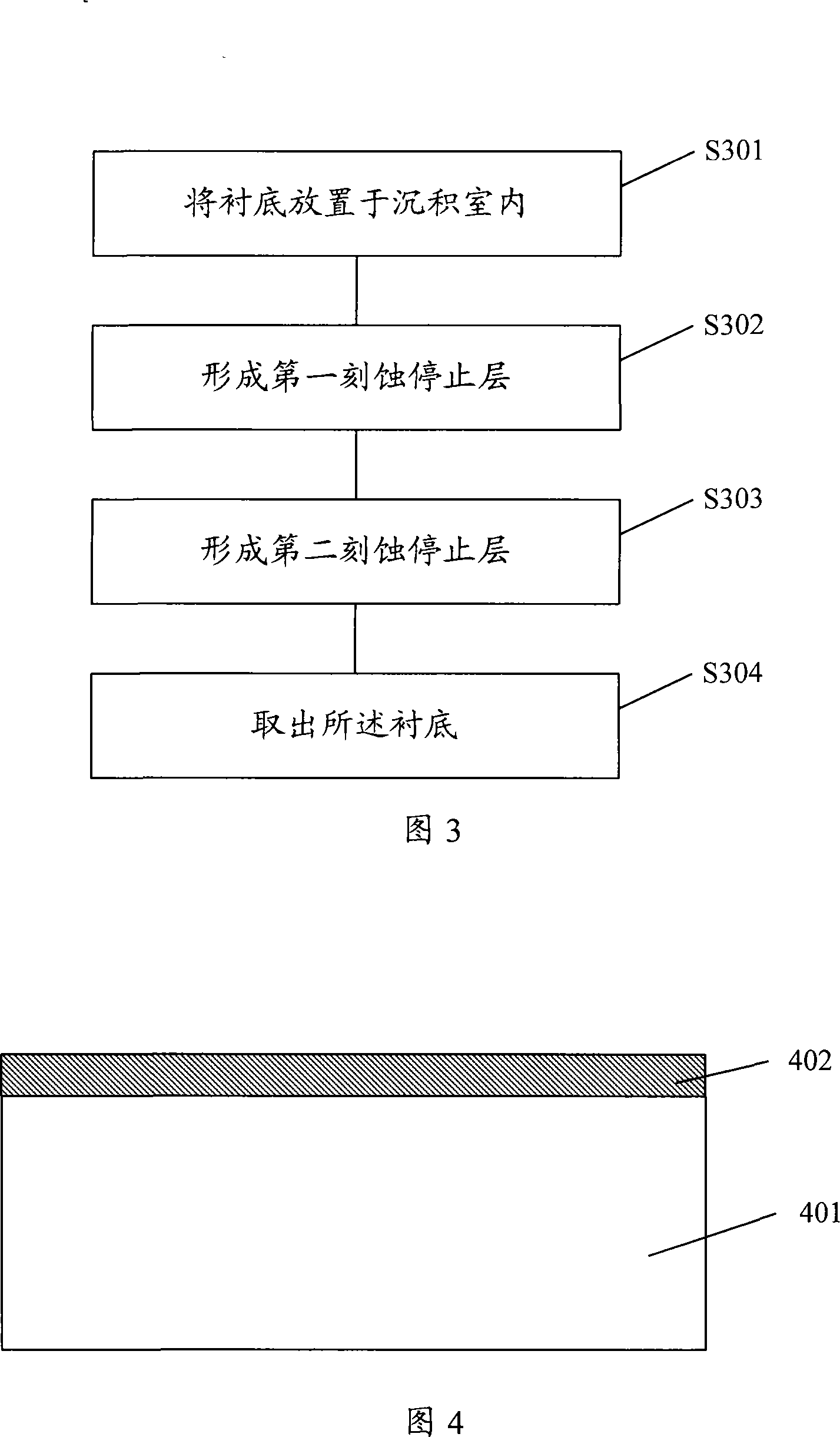

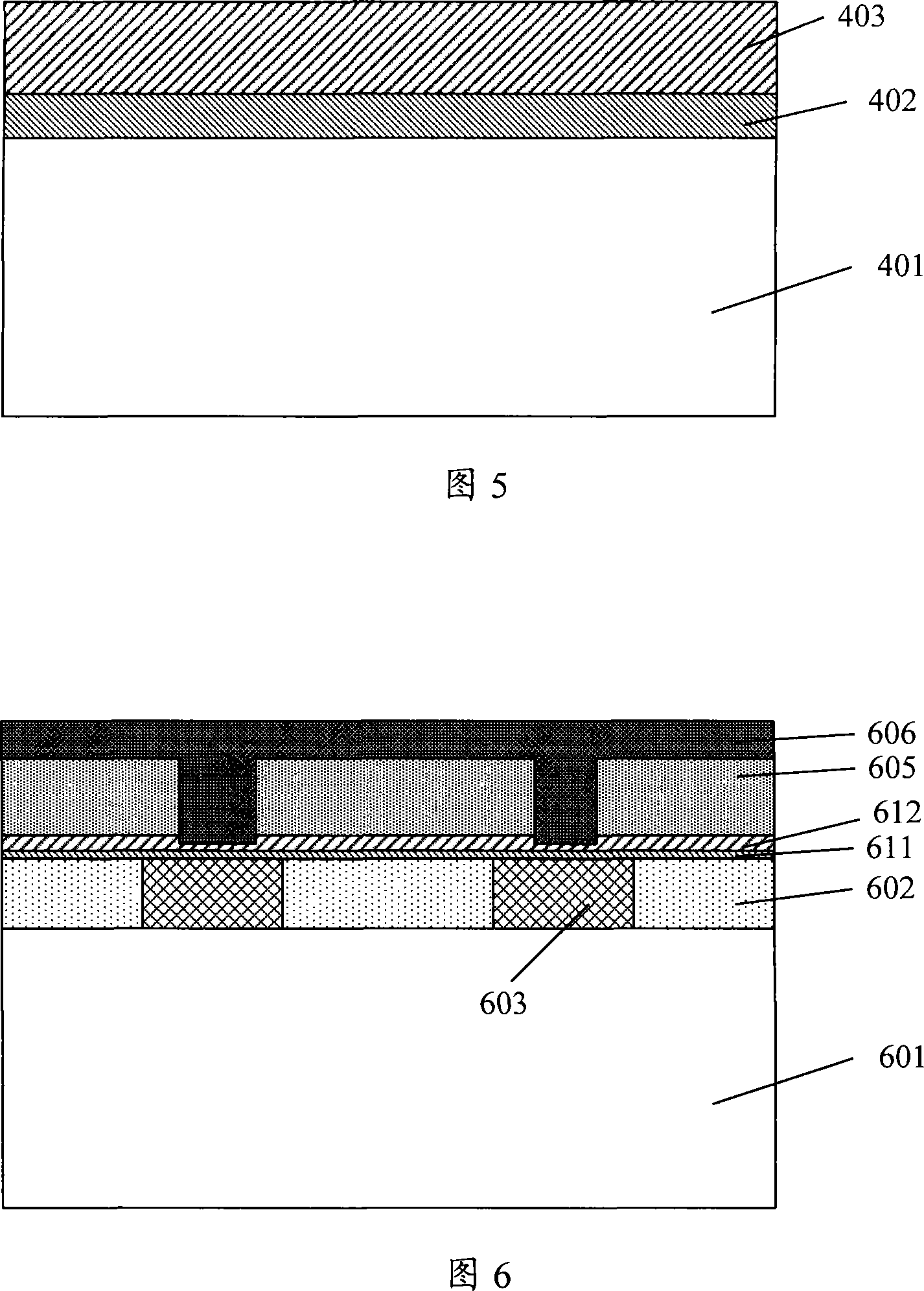

Etching stopping layer, semi-conductor device with through hole and forming method thereof

ActiveCN101459058BReduce nitrogen contentHigh nitrogen contentSemiconductor/solid-state device detailsSolid-state devicesNitrogenSemiconductor

The invention discloses an etch stop layer which at least comprises a first etch stop layer and a second etch stop layer on the first etch-stop layer, wherein nitrogen content of the second etch stop layer is higher than that of the first etch stop layer. The invention further discloses a manufacturing method of the etch stop layer, a semiconductor device which utilizes the etch stop layer and isprovided with through holes, and a method thereof. By utilizing the etch stop layer, a front material layer connected with the etch stop layer can be effectively prevented from nitridation, thereby achieving the purpose of reducing circuit resistance and improving shaping quality of circuits.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

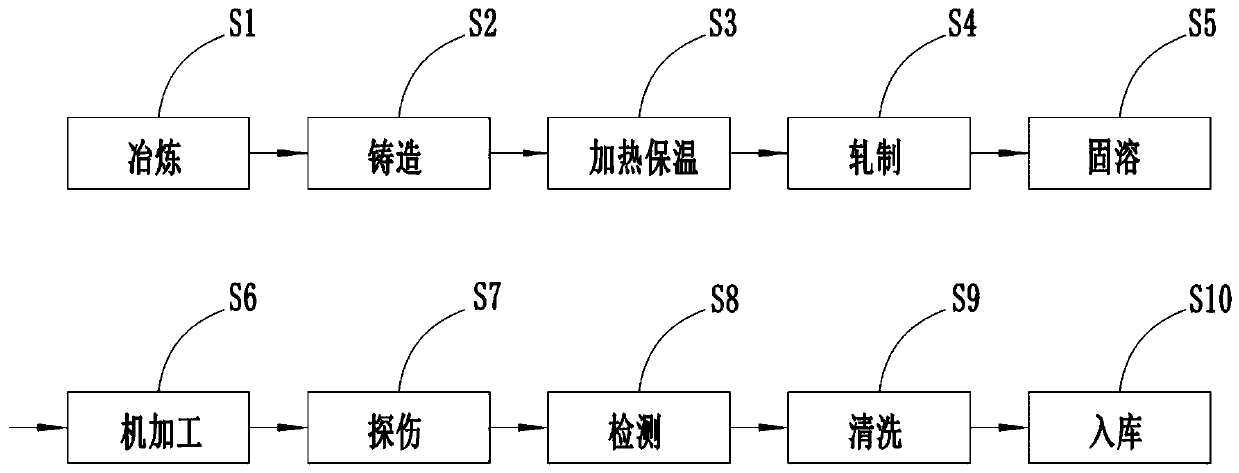

High-temperature-resistant and water-cooling-free roll and preparation method thereof

ActiveCN111534755AImprove creep strengthImprove high temperature strengthFurnace typesHeat treatment furnacesHeat conservationMachining

The invention discloses a high-temperature-resistant and water-cooling-free roll and a preparation method of the high-temperature-resistant and water-cooling-free roll. The high-temperature-resistantand water-cooling-free roll is prepared from the following components in percentage by weight: 0.3 to 0.5 percent of C, 0.5 to 0.8 percent of Si, 0.2 to 0.4 percent of Mn, 0.5 to 1.5 percent of Ni, 30to 31 percent of Cr, 2.1 to 2.3 percent of Mo, 0.15 to 0.3 percent of V, 4.5 to 6.0 percent of Al, 1.3 to 1.8 percent of W, 0.1 to 0.2 percent of Ti, 0.15 to 0.2 percent of Nb, 0.08 to 0.15 percent of N, and the balance of Fe and other inevitable impurity elements. The preparation method of the high-temperature-resistant and water-cooling-free roll comprises the steps of smelting, casting, heating and heat preservation, forging, rolling, solid solution treatment, machining, flaw detection, detection, washing and warehousing. The high-temperature-resistant performance of the water-cooling-freeroll can be remarkably improved, the cost performance is high, and oxidation accumulated humps can be effectively prevented.

Owner:江苏良工精密合金钢有限公司

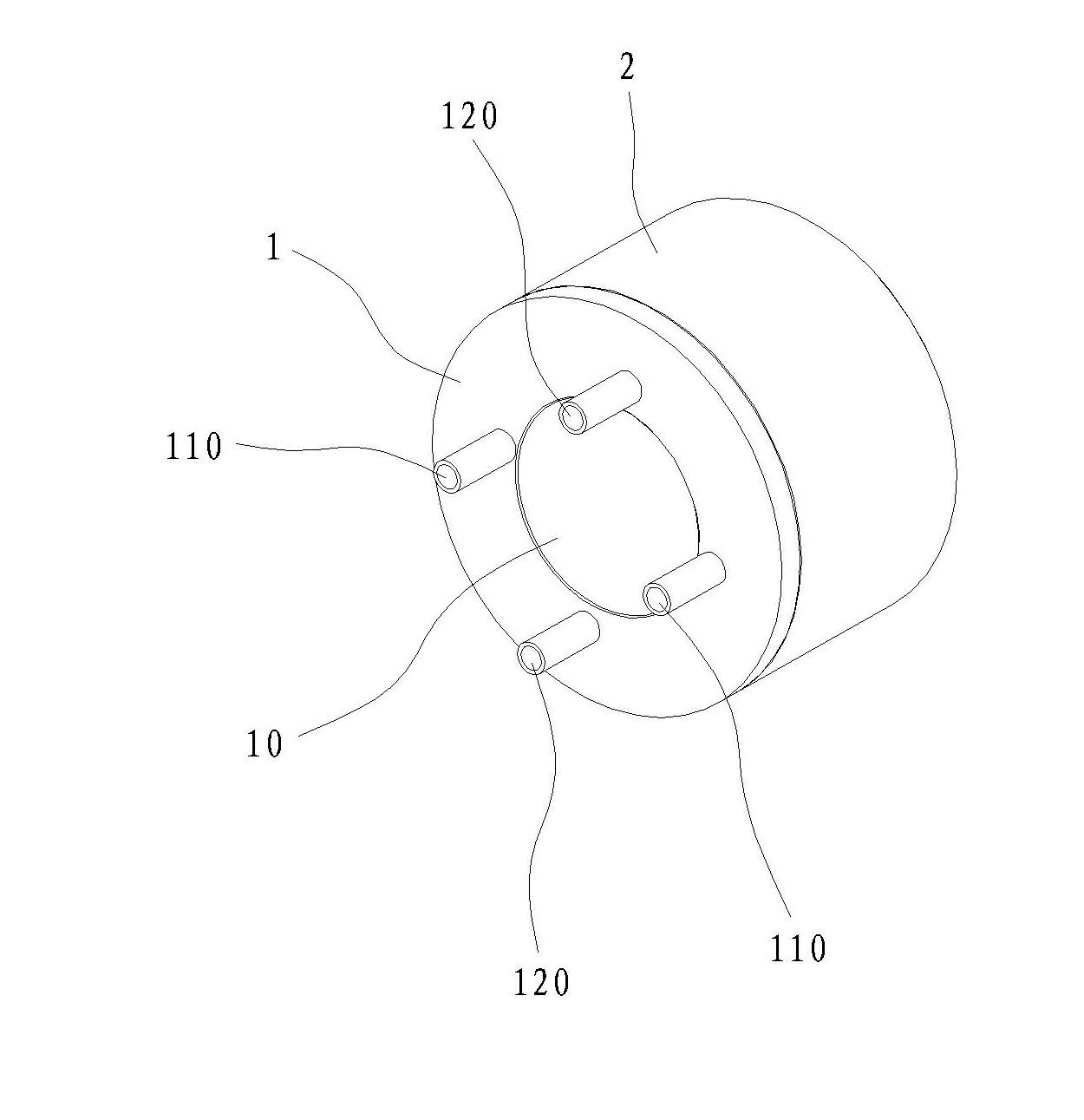

Plasma arc cladding wear-resistant and corrosion-resistant coating on titanium alloy surface and preparation method thereof

The invention discloses a plasma arc fusion covering abrasion-resistant and corrosion-resistant coating on a titanium alloy surface and a preparation method of the plasma arc fusion covering abrasion-resistant and corrosion-resistant coating. Powder with nickel base components serves as a powder supplying material, and by means of appropriate plasma arc technological parameter selection and combination of a related protection cover and a gas protection device, oxidation and nitridation of substrate base metal in the fusion covering process are effectively prevented; and abrasion-resistant and corrosion-resistant intensifying of the titanium alloy surface is conveniently achieved on plasma arc equipment which is relatively low in price, and higher fusion covering efficiency is acquired through the beneficial effect that the power of the plasma arc is large; and the hardness of a fusion covering layer acquired after fusion covering gives priority to a nickel base solid solution, TiC, TiB2, CrB and other wild phases are distributed in the fusion covering layer, and the hardness of the fusion covering layer can reach about 1,200 Hv.

Owner:邓相宇

Device for improving welding quality of large-size pipeline easily

InactiveCN106903412AImprove welding qualityTight shielding gasMetal working apparatusTubular articlesEngineeringNozzle

Owner:CHENGDU DAMO PETROLEUM TECH CO LTD

Plasma jet-stream protective cover

InactiveCN102618815BPrevent getting involvedPrevent oxidationMolten spray coatingPlasma jetEngineering

The invention discloses a plasma jet-stream protective cover, which comprises a jet-stream core body and a jet-stream core body center axial direction through hole. One end face of the core body is provided with two groups of air intakes. A core body perisporium is correspondingly provided with two groups of air outtakes. The two groups of air outtakes are communicated with the corresponding air intakes so as to form an inner layer of protection air and an outer layer of protection air. An inner ring is connected to the jet-stream core body and is cooperated with one group of air outtakes on the front end of the core body perisporium. An outer ring is connected to the jet-stream core body and is cooperated with the other group of air outtakes of the core body perisporium. The jet-stream core body, the inner ring and the outer ring are together assembled into a cover structure. One end of the cover structure is used for air suction, and the other end forms two layers of protection air rings and is extended forward so as to enable the plasma jet-stream to be effectively separated from the atmosphere. One protective device is installed on one spray gun of an atmosphere plasma spray coating device, completely-molten or half-molten powder is protected inside the protective air along with the flame through the protection of the air so as to be separated from the atmosphere, the oxidization and nitrogenization of the powder in a high temperature can be reduced, and the quality of a target coating can be improved.

Owner:WUHU YINGRI TECH CO LTD

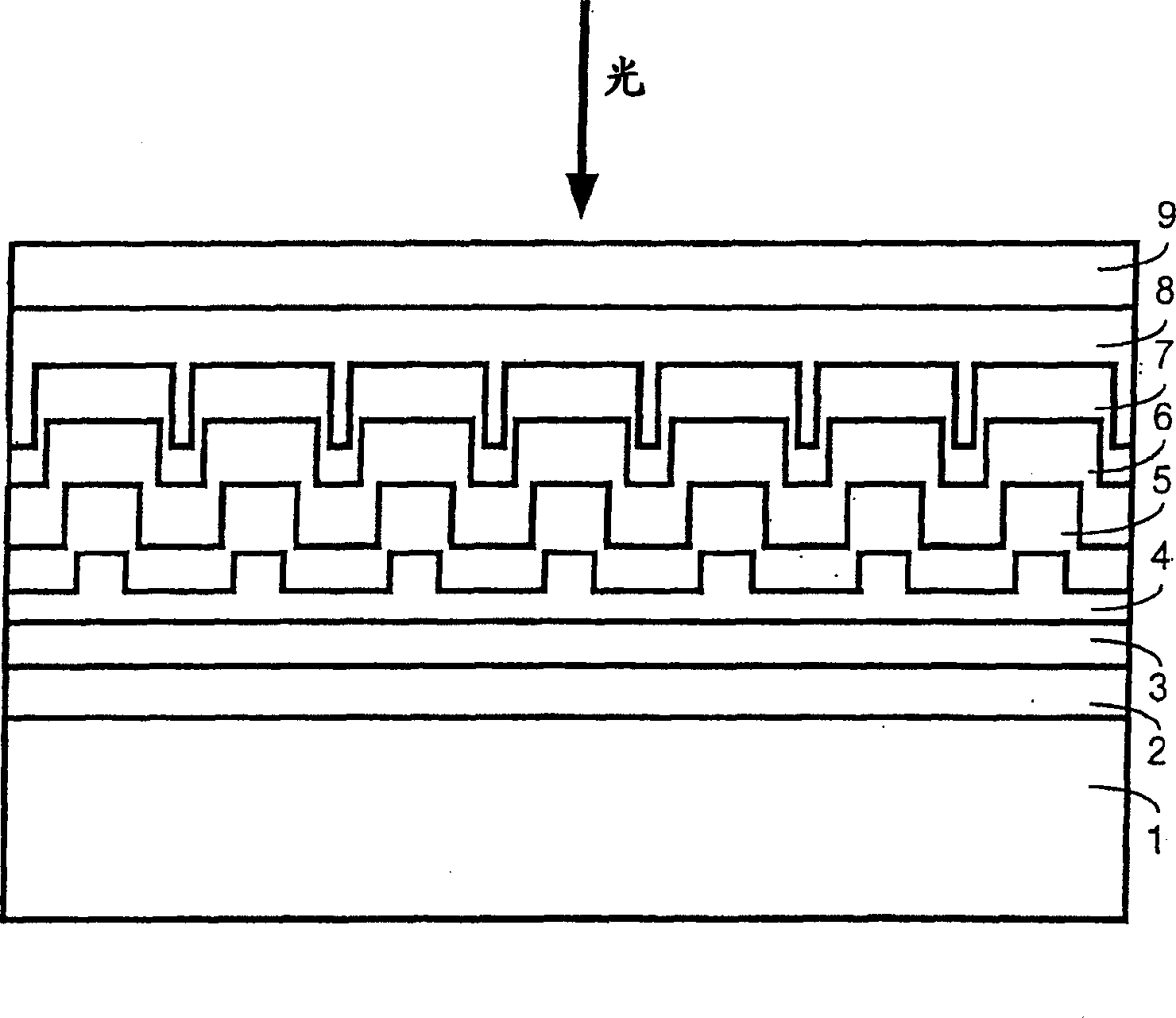

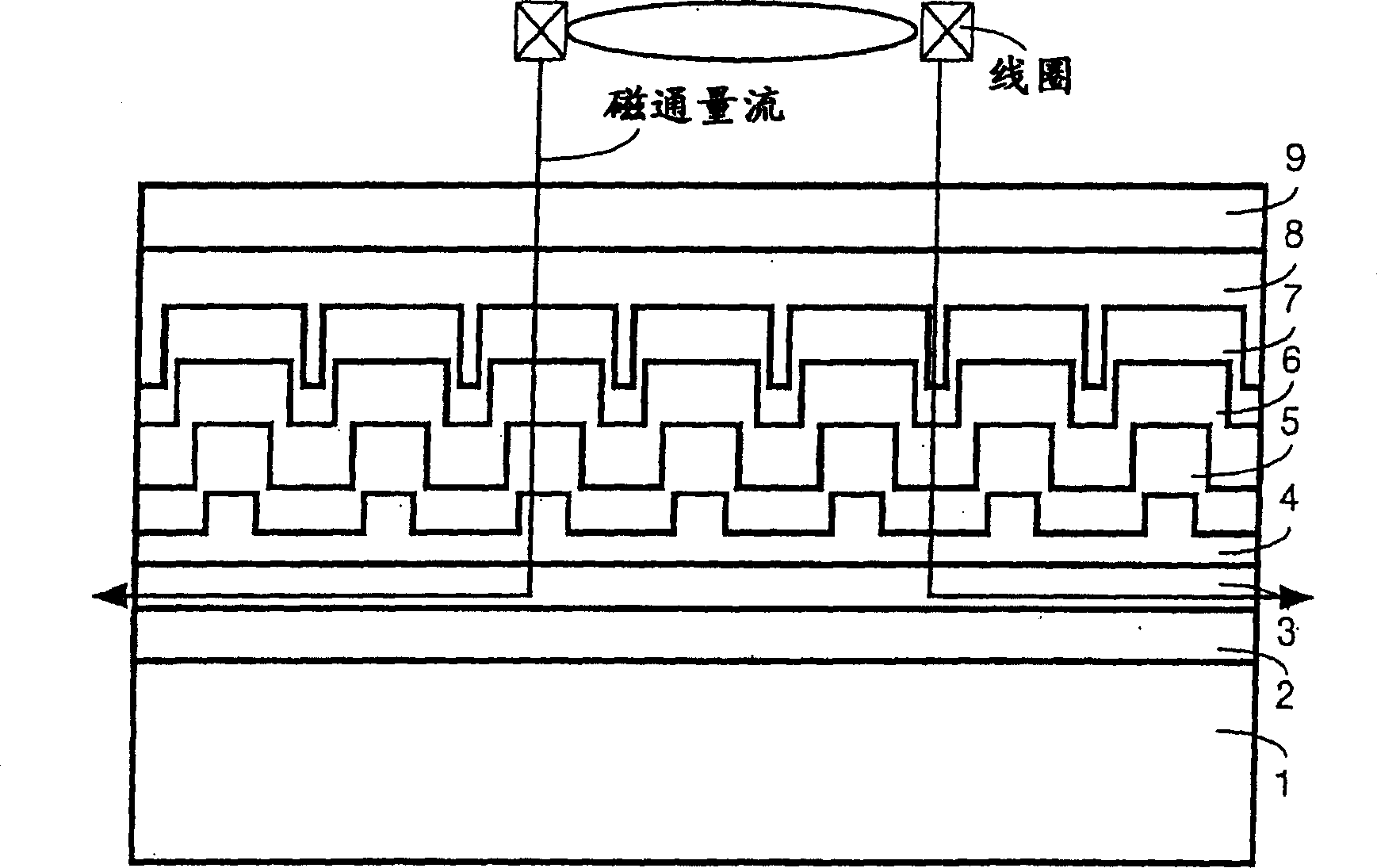

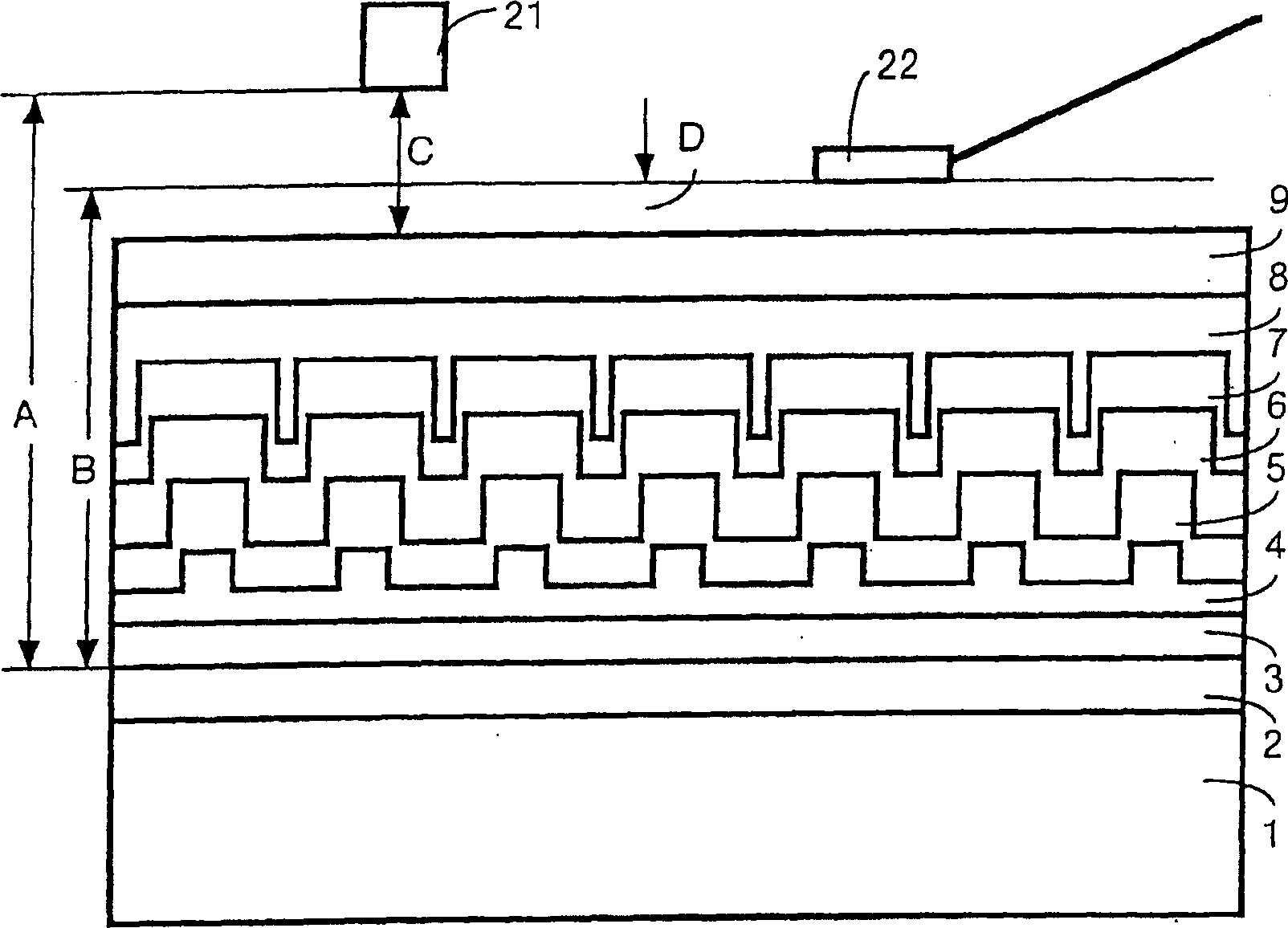

Optical magnetic recording medium

InactiveCN1582474APrevent oxidationPrevent nitridingLayered productsRecord information storageDielectricRecording layer

Owner:FUJITSU LTD

Mg-Sr alloy with extremely excellent die-casting performance

The invention discloses a magnesium-strontium alloy with extremely excellent die-casting performance when smelted between 700-800 degrees and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Sr: 1.0‑1.5wt.%, Ba: 0.4‑0.8wt.%, Co: 0.4‑0.9wt.%, Si: 1.2‑1.5wt.%, Ge: 0.6 ‑0.8wt.%, Gd: 0.1‑0.2wt.%, Ce: 0.2‑0.4wt.%, B: 0.3‑0.5wt.%, and the balance is magnesium. The magnesium-strontium alloy material has good casting properties and is suitable for pressure casting of thin-walled parts under a protective atmosphere. It is especially suitable for casting lightweight structural materials that require lightweight features, and has a huge market prospect.

Owner:GUANGZHOU YUZHI TECH CO LTD

A method for preparing boron-containing microalloy steel by using boron-containing pig iron as a boron-adding agent

The invention provides a method for preparing boron-containing micro-alloy steel by using boron-containing pig iron as a boron charging agent, and belongs to the technical field of metallurgy. The method comprises the following steps: (1) preparing industrial pure iron, the boron-containing pig iron, ferro-titanium, manganese metal, iron-carbon alloy, ferro-silicon alloy and pure aluminium serving as raw materials according to predetermined components; (2) adding the prepared industrial pure iron and iron-carbon alloy to an induction furnace, melting the materials, sequentially adding the ferro-silicon alloy, the pure aluminium, the ferro-titanium, the manganese metal and the boron-containing pig iron, melting under a vacuum condition, and feeding argon for refinement; (3) after ending refinement, casting into cast ingots, then heating to 1200+ / -10 DEG C, and preserving heat for 0.5-2 hours; (4) rolling the cast ingots subjected to heat preservation by two stages; and carrying out final rolling, thus obtaining roll steel; and (5) continuously cooling the roll steel to 530-560 DEG C at the rate of 40-50 DEG C / s, and then carrying out air cooling to room temperature, thus obtaining the boron-containing micro-alloy steel. The method has the advantages that the composite cost is low, the industrialization is easy to realize, and the prepared product has excellent performances and good application prospect.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com